UV-cure digital printing continues to be a fast-growing segment in the wide-format printing market. InfoTrends—an industry research firm based in Weymouth, Massachusetts—predicts that the total system revenue from wide-format UV-curable inkjet printing systems—which includes hardware and ink—will grow from just over $2.7 billion in 2015 to about $4.3 billion in 2020, for a compounded annual growth rate of about 10 percent.

UV固化数码喷印技术在宽幅喷印市场仍然是一个迅速发展的领域。InfoTrends是一家位于马萨诸塞州韦茅斯的行业研究公司,他们预测宽幅UV固化喷墨打印系统的总收益——包括硬件和油墨在内——将会从2015年刚超过270亿美元,到2020年上涨至大约430亿美元,其复合年增长率约为10%。

One of the key reasons for the rise of UV-cure inkjet technology is that it offers the widest range of printable substrates, which allows shops the option to expand their application offerings to their client base.

UV固化油墨技术迅速发展的一个关键原因是,它可以提供最大范围的承印物,帮助商铺扩展供应给客户群的应用产品种类。

The beauty of UV systems is that the ink remains uncured until exposed to UV light. Experts say this helps to keep the inkjet nozzles open and reduces the need for maintenance and maintenance cycles. The process can save ink and increase use time compared to that of solvent ink chemistry.

UV系统的优势就在于其油墨在UV照射之前都不会被固化。专家说,这样有助于保持喷嘴处于打开状态,减少维护需求和周期。与弱溶剂型化学油墨相比,该过程可以节省油墨,延长使用寿命。

Let's take a look at the current state of UV-curing systems in wide format production inkjet printers, how they work and where this technology is heading.

现在让我们来看看现阶段UV固化系统在宽幅喷印领域的发展状况、工作原理以及发展方向。

Versatile and Effective

通用性和有效性

Ken Hanulec, vice president of marketing, EFI Inkjet Solutions, Meredith, New Hampshire, reports that UV- and UV-LED curing are among the most efficient, versatile and effective methods for wide- and superwide-format imaging. “Digital UV inkjet ink formulas include reactive agents that cure the ink when exposed to a UV lamp mounted on the printer," he says, "UV-LED inkjet works in a similar way, but with reactive agents in the ink that respond to the narrower range of UV light waves emitted by an LED-based UV lamp.”

新罕布什尔州梅瑞狄斯的EFI喷墨解决方案公司营销副总裁肯·哈努拉称:“UV-和UV-LED固化在宽幅和超宽幅成像领域是最高效、通用性最高、最有用的方案。数码UV喷墨配方包括,固化在UV照射下的油墨的活性药剂,UV-LED喷墨的工作原理也是与之类似,但是带有活性药剂的油墨在用LED的UV光照时,会发出较窄范围的UV光波。”

Both UV and UV-LED systems give users the advantage of instantly dry prints, Hanulec continues. These can be immediately finished and/or delivered to customers right after printing. “Since this work often involves very large graphic prints," he says, "having instantly dried prints presents an extra benefit because it eliminates the tremendous amount of space that printed graphics might otherwise need to sit out to dry.”

哈努拉说:“UV和UV-LED系统都为用户提供瞬间干燥的喷印优势,这样就可以在喷印完成之后立即交付给客户。由于这类项目通常包含非常大的图文喷印作业,所以瞬间干燥的性能也会有额外的好处,它减少了大量风干喷印图文所需占用的空间。”

He adds that the other big benefit to both UV and UV-LED inkjet is the fact that they can adhere to a wide range of substrates. “Where some print technologies only work with flexible media, UV and UV-LED can be used with many different substrates, including specialty substrates such as glass and wood.”

他补充道:“UV和UV-LED喷墨系统的另外一大优势是,它们都能用于多种介质。有些喷印技术只能用于灵活的介质,而UV和UV-LED可以用于多种不同的介质,包括特殊介质,例如玻璃和木制品。”

How Inkjet UV-Curing Works

UV固化喷墨系统工作原理

“The ink consists mainly of photoinitiators, monomers and oligimers; and when together in an ink formula and they are exposed to UV light, it triggers a chemical (cross linking) process that transforms the ink into a solid film that tightly adheres directly onto the substrate’s surface," says Roberts. "This all happens within a fraction of a second."

罗伯特说:“该油墨主要是由光引发剂、单体和低聚体组成的,当这些物质合成在一起形成油墨并暴露在UV光照下时,它会触发一个化学(交联)过程,将油墨直接粘附在介质表面形成结实的贴膜,通常这个过程很快就可以完成。”

Heather Roden, product marketing manager, FujiFilm North America Corporation, Graphic Systems Division, Hanover Park, Illinois, puts it this way: “Photoinitiators in the ink react to UV light, which triggers the cross linking, or polymerization—the monomers and oligimers in the ink come together to form a dry film," she says.

伊利诺斯州汉诺威公园富士北美公司图文系统部门的产品经理希瑟·罗登对这个化学过程做了解释:“油墨中的光引发剂在UV光照下起了反应,从而触发交联过程或聚合作用,油墨中的单体和低聚体结合在一起形成干燥的贴膜。”

“Perhaps you’ve heard the term ‘Instantaneous Cure’ inks,” adds Jay Roberts, product manager, UV Products at Roland DGA Corp., Irvine, California. "This is the precise difference between the UV-curable and solvent ink families. UV-curable inks are ‘cured’ once they are exposed to wavelengths of UV light.

加利福尼亚欧文罗兰DGA公司UV产品部门经理杰伊·罗伯特说:“你或许听说过‘瞬时固化’油墨,它是UV固化油墨和溶剂型油墨之间最显著的区别点。UV固化油墨暴露在UV光照下立即就会被‘固化’”。

Conventional UV-curing Vs. UV-LED

传统UV固化系统Vs.UV-LED系统

Roberts points out the two main types of UV lamps being employed in large-format UV-curing printers include mercury vapor UV lamps and the LED-based UV lamps which rely entirely on LED lamps for the source of UV radiation.

罗伯特指出,这两种主要用于宽幅UV固化喷印机的UV照射系统,包含汞蒸气UV照射器和完全依靠LED灯来获取UV辐射源的照射器。

“Unlike most mercury vapor UV lamps, LEDs come to full brightness immediately without need for a warm-up time or ‘burn in’ time as we call it in the printing world," Roberts says. "The other dramatic difference is the UV wavelength produced by the lamps. In digital printing, the mercury-vapor UV lamps produce light waves in the 365nm spectrum (Type D lamps), while the LED-based UV lamps produce wavelengths at about 390nm.”

罗伯特说:“与大多数汞蒸气UV照射器不一样的是,LED无需预热时间或喷印行业所谓的‘煲机’时间。它们之间另一个显著差别是照射器会发出不同波长的UV光波。在数码喷印领域,汞蒸气UV照射器发出的光波波长在365nm范围内(D型照射器),而基于LED的UV照射器发出的光波波长约为390nm。”

This means that the intensity of the radiation is dramatically less with LED-based systems. He says it can be illustrated two ways: First, the LED lamp produces less heat and second the LED uses less energy to illuminate. The ink that is used to print with mercury vapor lamps is quite different than the UV-LED system's inks as well. The chemical make-up directly corresponds to the light intensity (wavelength) and as such, the inks cannot be intermingled. They are developed specifically for the light wavelength of either mercury vapor or UV-LED that the particular system employs.

这就意味着,基于LED的UV照射系统辐射强度会明显降低。它有两种照射方式:产生更少热量的LED照射器,消耗更少能源的LED照射器。用于汞蒸气照射器喷印的油墨和用于UV-LED喷印系统的油墨也是不一样的。油墨中的化学成分直接对应于光照强度(波长),因此油墨不能混合使用,必须专门生产用于特定波长的汞蒸气或UV-LED系统的油墨。

Technical Similarities and Differences

技术的相似性与差异性

“As discussed, the mercury-vapor UV lamps use a greater intensity light wavelength. With this greater intensity, there are the two major drawbacks. The lamps use much more power and they are significantly larger than the LED lamps, says Roberts.

罗伯特说:“如前所述,汞蒸气UV照射器采用的是更大的光照强度。在这种光照强度下,会有两个主要缺陷。UV照射器会消耗更多的能源,并且它们的尺寸比LED照射器大得多。”

“The mercury-vapor lamps are powered by 220-volt power, while the UV-LED lamps are powered under 110 volts. While the more powerful mercury-vapor lamps produce better adhesion on some materials, they may sometimes blister and warp other materials which might be sensitive to the heat the vapor lamps generate," he says. "The average mercury vapor lamp produces temperatures up to 200 degrees Fahrenheit, while UV-LED produce 104 degrees Fahrenheit.” He points out that this temperature difference allows UV-LED inkjets to print on sensitive films and generally a wider range of substrates, even without adhesion promoters, which are used with both lamp sources.

他说:“汞蒸气照射器是由220伏电源供电,而UV-LED照射器是由110伏电源供电。在较高电源供给下的汞蒸气照射器会更好地粘附在一些介质上,但是它们可能会在其他对蒸汽热度敏感的介质上,产生水泡或变形。汞蒸气照射器产生的平均蒸汽温度可以达到200华氏温度,而UV-LED则只有104华氏温度。这种温度差异使得UV-LED喷墨系统在没有助粘剂的情况下,也可以在敏感贴膜和更大范围的介质上进行喷印。”

An Integrated Approach

一种综合方案

But not all perspectives on cure systems are alike. Christopher Guyett, sales and marketing coordinator at printer manufacturer Durst Image Technology U.S., LLC, Rochester, New York, points out that Durst’s approach to LED has been to integrate it where it can solve a problem or advance the technology. “Some industrial Durst innovations have integrated LED to some extent," he says. "The strongest advantage to LED is the reduction of heat when compared to high-energy UV. In cases where excess heat has an adverse effect on the substrate being used and the underlying hold-down method is insufficient to overcome the problem, LED-based lamps can be a solution.

然而,并不是所有人对固化系统的看法都是一样的。纽约罗契斯特市的Durst图像技术公司喷印机生产部门销售经理克里斯托夫·盖耶特指出:“Durst推出一种综合LED方案,它能够解决问题或推进技术发展。Durst的一些行业创新技术在某种程度上将LED集成在一起。LED与高能量的UV相比最大的优势就是其热量的减少。多余的热量会对所使用的基质产生不利的影响,并且底层压紧方法并不能解决这个问题,因此在这种情况下,基于LED的照射器就是一个好的选择。”

"The disadvantage is that specially formulated inks are then required [that can react to the narrow wavelengths produced by the LED] and may not perform on as wide an array of materials. Further, as production speeds increase, there is reduced ability to obtain the cure level necessary for some materials.”

盖耶特说:“基于LED照射器的缺点是,它需要特殊配制的油墨[对应于LED照射器发出的光照强度],且不能用于多种材料。此外,随着生产速率的提高,一些材料可能达不到它们所需要的固化水平。”

He adds that Durst also has been on the leading edge of one “big” trend—a progression to digital imaging based on aqueous inks, as another option to conventional UV-curable and solvent-based inks. “The name of the program is Durst Water Technology," Guyett says. Development of the system, "is largely driven by two factors," Guyett continues. "New governmental 'green' directives (such as the European REACH regulations) and further growth into the interior-print, point-of-sale packaging, and P.O.P. segments.”

他补充道,Durst正处于一个“大”趋势的最前沿——基于水性油墨的数码成像技术,以及传统UV固化和溶剂型油墨技术。盖耶特说:“该项目的名字为Durst水技术。这项技术主要是由两个因素驱动而成。最新官方‘绿色’指令(例如欧洲REACH规定),以及内部喷印、销售点包装和P.O.P. 的进一步发展。”

New Developments

新的发展方向

At the same time other printer manufacturers are building on UV-LED technology and incorporating other advancements—such as a nitrogen gas blanket built into the printing zone—to develop a truly high-speed LED-based UV-cure printer. With this system the nitrogen blanket inhibits the presence of oxygen which hampers curing—allowing the ink to fully cure and at much faster speeds. Such is the case with EFI's new VUTEk GS5500LXr Pro, which offers printing speeds of 2,000-4,000 square feet an hour.

与此同时,其他的喷印机制造商也正在发展UV-LED技术并整合其他先进技术——例如在喷印区域设置氮气层——制作一台真正高速的基于LED的UV固化喷印机。在这个系统中,氮气层会抑制阻碍固化过程的氧气含量,这样油墨就能以更快的速度完成固化过程。这种情况就适合用EFI公司的新型VUTEk GS5500LXr Pro喷印机,它的喷印速度可以达到每小时2000到4000平方英尺。

“LED inkjet used to be limited in speed capabilities," Hanulec says. "Printer manufacturers had not devised a way to cure ink fast enough using LED-based UV systems compared with other curing methods,” says Hanulec. “Our engineers created a system that removed oxygen from the surface where ink and substrate meet, replacing it with nitrogen, which allows the ink to cure more thoroughly and at faster speeds. This ‘nitrogen blanket’ process was a breakthrough for us in terms of bringing LED inkjet imaging into the high production space. But in the time since we first introduced production-speed LED inkjet printing to the marketplace, our engineers have also established ways to still maintain high quality and production speeds without a full nitrogen blanket process.”

哈努拉说:“LED喷墨系统过去的喷印速度是有限的。与其他固化方案相比,喷印机制造商还没有想出,适用于基于LED的UV系统的快速固化油墨方案。我们的工程师设计了一个系统,它可以将油墨和介质接触表面的氧气替换为氮气,这样就能以更快的速度使得固化过程更彻底。该‘氮气层’处理方案是我们将LED喷墨成像系统带入高产率领域的一个重大突破。但是在我们首次将高生产速度引进到市场中之前,我们的工程师也在不断地探索新技术,就是在没有氮气层处理方案时,仍然能够保持高质量和高生产速度。”

He points out that this process enabled them to also create a lower-cost production LED inkjet device, the EFI H1625 LED printer. “Today that model is a top seller among smaller businesses seeking to offer the versatility of LED as an entry point into the growing digital print display graphics space,” he says.

他指出,这个处理过程使得他们能够制造出一台更低成本的LED喷墨设备——EFI H1625 LED喷印机。他说:“目前这个模型在许多小型企业中是最热销的产品,企业用它来展示LED的通用性,作为跻身于高速发展的数码喷印领域的切入点。”

EFI Rolls Out New Inkjet Technology

EFI公司推出新型喷墨技术

As for future developments, Hanulec says that EFI has recently unveiled its own new water-based inkjet platform that also employs UV lamps. “Our AquaEndure inkjet technology is a water-based inkjet platform that really addresses what signage and graphics companies need to do in digital printing," he says. "Because it is economical and offers high-quality imaging with strong color fidelity. Part of the advantage of the new ink is that it has a low-energy, which means it can be used with a wide range of substrates. It also has a very eco-friendly profile and no odor.”

关于未来的发展方向,哈努拉说:“EFI公司最近推出新型以水为基础的喷墨平台,同样适用于UV照射器。我们的AquaEndure喷墨技术是以水为基础的喷墨平台,能够真正处理标识公司在数码喷印中的需求。它经济合算,可以提供高质量的图像,且图像有很强的色彩保真度。这种新型油墨的优点是,它的能耗很低,这意味着它可以用于多种基质,同时它还很环保、且没有气味。”

He explains that starting out, AquaEndure will address the roll-to-roll market for grand-format interior décor applications, wall coverings and more. “But we intend to expand this technology to many future generations of printers, including hybrid roll/flatbed printers," Hanulec adds. "Ultimately, the ink will be an ideal fit for just about anything that is currently printed today with UV, LED or latex across the signage and graphics and packaging spaces.”

他解释说:“一开始,AquaEndure喷墨技术针对的是宽幅室内装饰、墙纸等应用的卷对卷市场。但是我们打算扩大这项技术在许多未来喷印机中的应用,包括混合卷筒式/平板式喷印机。我们的最终目标是,使得该油墨成为标识领域目前所有UV喷印、LED或乳胶技术的理想选择。”

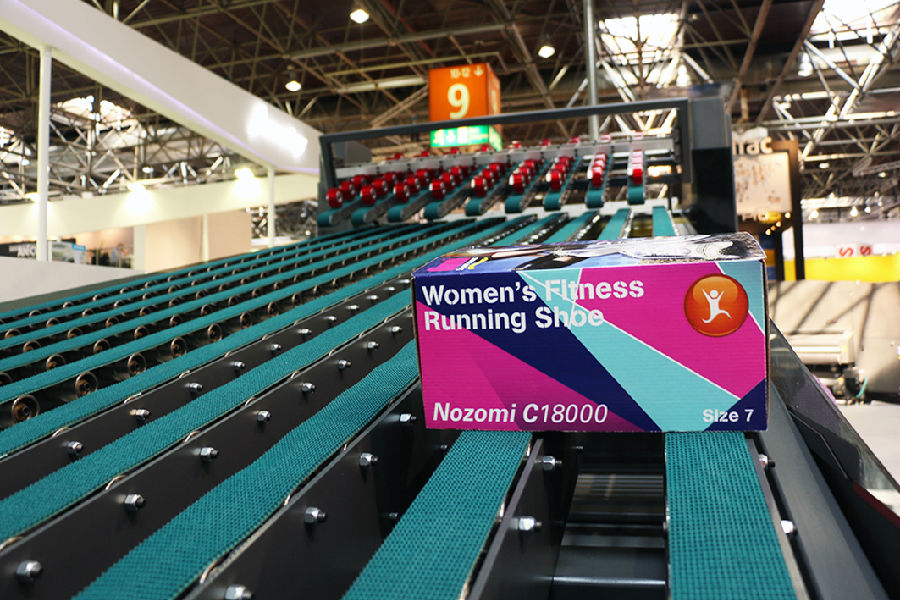

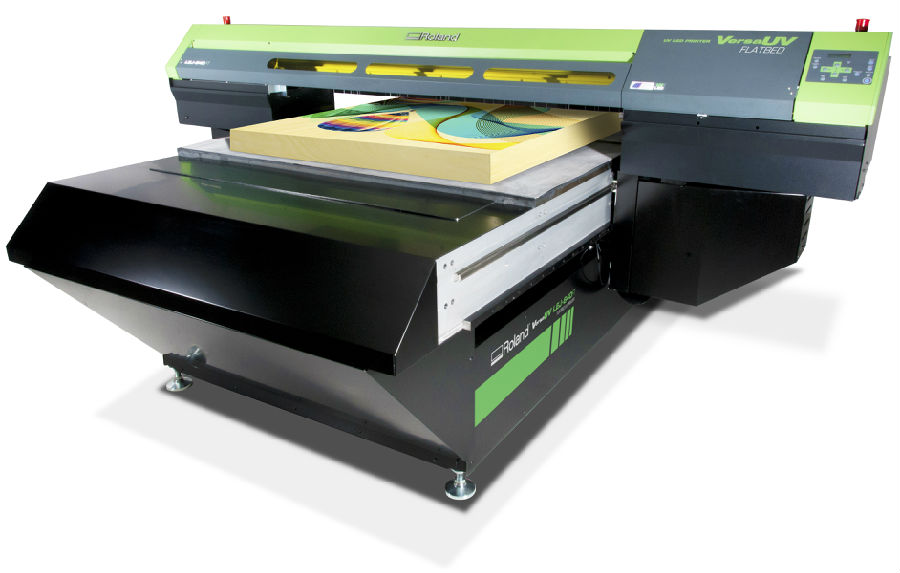

EFI did a live demonstration of its AquaEndure ink system at the recent drupa show this year, where it also debuted the company's new Nozomi C18000 single-pass LED press. The high-volume, high-speed flatbed printer employs a UV-LED curing system and is aimed at high-productivity corrugated board work. But future versions of the unit will be aimed at the sign and graphics markets, Hanulec says, adding that "in the future our AquaEndure inks will run in the Nozomi platform."

EFI公司在今年的德鲁巴展会上,对AquaEndure油墨系统做了现场演示,另外,它还推出新型Nozomi C18000单程LED喷印机。这个大容量、高速率的平板喷印系统采用UV-LED固化系统,用于高产量的波纹纸板生产,但是该公司未来的产品将会针对标识图文市场。哈努拉说:“在未来,我们的AquaEndure油墨将会用于Nozomi平台。”

“AquaEndure extends the benefits even further than traditional UV-LED," he continues. "It will have a cost advantage over several other types of imaging technologies where printing companies are finding that ink prices are really cutting into margins. AquaEndure will also have some applications in food packaging that are not possible today with UV or UV-LED inks, so that creates a whole new opportunity for a range of applications where high-quality and value are important,” he concludes.

他说:“AquaEndure比传统UV-LED技术进一步扩展了优势,它和其他几种成像技术相比,在成本上有明显的优势,因为喷印公司发现油墨价格降低了企业的利润率。AquaEndure在食品包装领域也有应用,而目前的UV或UV-LED油墨却不具备这个性能,因此它为许多高品质和高价值应用创建了一个全新的机会。”

Durst Water Technology

Durst水技术

Guyett says that Durst’s water-based Functional Aqueous (WT Inks), and its related printers, produce a litho-like print quality at production speeds. “These systems offer odorless operation and are more eco-friendly than existing solutions," he says. "Printers include the Rhotex 322 and Rhotex HS soft-signage printers, and the new Rho WT 250 HS and Rho 180 TR aqueous printers. The Rho WT 250 HS and Rho 180 TR are not yet available in every region where Durst does business.

盖耶特说:“Durst以水为基础的功能水性油墨(WT油墨),及其相关喷印机,会生产出与平板喷印类似的产品质地。这些系统提供无气味的操作环境,比现有解决方案更加环保。这些喷印机包括Rhotex 322、Rhotex HS软性标识喷印机,以及新型Rho WT 250 HS、Rho 180 TR水质喷印机。Rho WT 250 HS、Rho 180 TR在Durst已开展业务的地区尚不可用。”

“Durst's Water Technology utilizes a new proprietary Quadro Array piezo inkjet printhead technology, that generates minimal heat and features a circulating ink system. It prevents the vaporization of the water molecules within the ink, eliminates premature ink curing and clogging of nozzles to ensure operational readiness. Durst’s aqueous-ink systems can print on coated and uncoated materials, both rolled and rigid substrates.”

他说:“Durst水技术采用新专利Quadro Array压电式喷墨喷头技术,它产生的热量最低,并且以循环油墨系统为特色。它可以防止油墨中的水分子蒸发,避免油墨固化过早,堵塞喷嘴以确保操作步骤准备就绪。Durst的水性油墨系统可以用于涂层材料和无涂层材料,包括卷材和硬性材料。”

He adds that Durst Water Technology is not seen as a replacement technology—at least not for the foreseeable future. But as technologies advance and demand for more “friendly” print processes grows, aqueous-based imaging will take a more prominent place in the industry.

他补充道,Durst水技术不是一种替代技术——至少在可预见的未来。但是随着技术的不断进步和对更“友好的”喷印过程需求的增长,以水为基础的成像技术将会在行业中占据更重要的地位。

“Durst’s Functional Aqueous (WT Inks) have a more complex formulation and dry quicker than latex ink systems, which results in considerably higher productivity," Guyett adds. "These inks, which are priced similarly to Durst’s other UV-curable inks, combine the benefits of UV-reactive molecules—adherence, durability, flexibility, low migration—with the advantageous properties of water. However, they are not subject to labeling requirements regarding environmental or health impact,” he explains.

盖耶特说:“Durst以水为基础的功能水性油墨(WT油墨),它的配方更加复杂且比乳胶油墨系统干得更快,这样就会大大地提高生产力。这些与Durst其他UV固化油墨价格相当的油墨,结合了UV反应分子的优越性能——依附性、耐用性、灵活性、低迁移性。然而,它们并不会受到环境或健康要求的制约。”