Grand-format textile printing was once the realm of a few shops, but as technology has come way down in price, it has made the technology more mainstream.

宽幅纺织喷印业务最初只有几家商铺在做,但是随着技术成本不断下降,它已经成为行业中的主流技术。

“We're printing at a higher resolution today, at faster speeds and at reasonable acquisition costs,” says Mike Wozny, senior product manager for EFI in Meredith, N.H. “It is really driving growth in this space. Each and every day new applications are coming online.”

新罕布什尔州EFI公司高级产品经理迈克·瓦兹尼说:“我们目前的喷印技术有着更高的分辨率、更快的速度和更合理的收购成本。它确实推动了该领域的经济增长,每一天都会有新的应用产品上线。”

From huge wall murals and awnings to umbrellas and backlit signs, grand-format textile printing is only limited by someone's imagination.

从巨大的壁画和遮阳篷到雨伞和背光标识,宽幅纺织喷印技术只是局限于人的想象力。

The prices of these machines have not come down, but instead of printing 200 to 400 square feet per hour, they can now print more than 8,000 square feet per hour.

这些设备的价格还没有降低,但是比起以前每小时200到400平方英尺的喷印速度,现在已经能达到每小时8000多平方英尺了。

“We're not charging 10 to 15 times the printer costs that we were 12 years ago. If you look at it from that perspective, we added value into the printer,” he said. “The total cost of ownership is a whole lot less today because of the square footage we are printing, at the acquisition prices we are charging.”

他说:“我们没有将喷印机的价格定为12年前的10到15倍。如果你从这个角度来看的话,会发现喷印机是有增值服务的。由于我们是以收购价格来定价喷印产品的,所以总资产成本少了很多。”

Jason Bartusick, president at Media One USA in Garden Grove, California, tells clients they should expect a three-month learning curve on this technology so they should budget between $15,000 and $20,000 for waste right off the bat. Even though that seems like a lot of money, Bartusick points out that sign companies need to make this move. “If they continue selling vinyl, they will get squashed,” he says.

加利福尼亚加登格罗夫Media One美国公司总裁杰森·巴图斯科告诉客户,他们应该制定一个关于这项技术的三个月学习曲线,这样他们就能立刻拿出15000到20000美元的预算。尽管这似乎是一笔不小的费用,巴图斯科指出,标识公司都需要这项投资。他说:“如果他们继续销售乙烯基,那么他们就会被其他竞争者比下去的。”

Dye sublimation transfer printing is the best option because the ink penetrates into the fabric and won't scratch off, like latex, he says.

巴图斯科说,染色升华传递喷印技术是最佳选择,因为油墨会渗透进织物内,不会像乳胶一样容易被刮掉。

At Media One, the cost to own a 10-foot printer is $250,000. The company sells 6-foot and 8-foot printers as well, which range from $50,000 to $110,000 apiece. It really depends on what market the sign shop is targeting whether it needs the grand-format printer.

Media One公司一台10英尺规格的喷印机成本为250000美元。该公司还出售6英尺和8英尺的喷印机,每台的价格为50000美元到110000美元不等。其喷印机价格实际上取决于标识商铺的市场定位,它是否需要宽幅喷印机。

Shops that move toward grand-format can produce all of the most popular items on the market today, including silicon edge graphics, trade show graphics, flags, table throws and architectural displays.

扩展了宽幅喷印业务的商铺,目前可以生产所有最受欢迎的产品,包括硅边缘图像、贸易展览图文、旗帜、架构展示等等。

“A lot of people are asking about it,” Bartusick says.

巴图斯科说:“很多人都在问这个问题。”

If a company moves into grand-format textile printing, they also should invest in an industrial sewing machine to finish off the pieces after they are done printing, he says. To cut the material, owners should look into a projection laser cutter. Unlike the i-Cut system, which uses dots to help align a graphic on paper and other substrates, a projection laser system projects the final image onto the cloth so that it doesn't stretch, warp or bow as it is printing. It stays exactly the right size, he says.

他说,如果一个公司开展了宽幅纺织喷印业务,那么他们还应该在工业缝纫设备方面进行投资,以便于能在喷印之后将其加工成成品。负责人可以考虑引进投影激光切割机来切割材料。与使用圆点来校准纸质和其他基质上图文的i-Cut系统不一样的是,投影激光系统将最终图像投影到布料上,保证其在喷印时保持合适的尺寸,不会拉伸、扭曲或弯曲。

If a shop only plans to print small things like flags or only sell to the retail market, they can get away with a smaller machine, he says.

他说,如果商铺只打算喷印旗帜类小物件,或其产品只出售给零售市场,那么他们配备较小规格的设备就可以取得成功。

“A lot of people getting into the 10-foot grand-format arena typically already have business,” says Ryan Burton, senior account specialist at Media One. They usually sub out this work to large wholesalers, but “once they get enough traction, they'll make the investment into grand-format.”

Media One公司高级客户专家赖安·伯顿说:“许多进入10英尺宽幅喷印领域的商铺通常是已经有了相关业务。他们通常将这项工作外包给大型批发商,但是一旦这类业务有足够的吸引力,他们就会在宽幅喷印领域进行投资。”

Burton suggests that people just starting out in the textile printing industry should start off with a smaller unit. Spend time building up that business and when they reach capacity, expand up into a larger machine.

伯顿建议人们刚开始进入纺织喷印行业时,应该用较小的设备来开展业务,当创建业务一段时间并达到极限时,就可以引进大型设备了。

There are a lot of advantages to going with fabric, he adds.

他补充道,织物喷印行业是有很多优势的。

“You can basically do any type of application you can do on a UV, solvent or inkjet machine, Burton says, including backlits, SEG framing systems, flags and point of purchase displays for retail stores. Textiles are higher quality in both look and feel. It costs about the same to print on textiles as it does to print on vinyl, and fabric has the added benefit of being lightweight, so it packs small and can be shipped across the country. It also doesn’t crack or bend if it is folded so it can be reused over and over again, unlike many vinyl signs.

伯顿说:“你可以在UV、溶剂型或喷墨设备上做出任何类型的应用产品,包括背光产品、SEG框架系统、旗帜以及零售商店的采购显示器。纺织品在外观和触感上都有较高的质量保证,它的成本与喷印在乙烯基上是一样的,并且织物的附加好处就是质量轻,因此它可以被包装成小包裹运往全国各地。同时,将织物折叠打包之后它也不会裂开或弯曲,因此它可以被重复利用,而乙烯基标识就不能这样做。”

Another benefit is that the dye sublimation inks used in textile printing are water-based so they are environmentally friendly. There are no toxic volatile organic compounds released during printing.

织物的另一个好处是,织物喷印使用的染色升华油墨是以水为基础的,因此它们很环保。在喷印期间不会释放出有毒挥发性有机化合物。

“That's why you see the market doubling and tripling year-over-year. I’ve been in the industry 20-plus years. I started out doing black and whites. I have watched it evolve. There is no question that the hottest thing is printing on fabric,” Burton says.

伯顿说:“这就是该市场利润同比增长两倍到三倍的原因。我在该行业已经20多年了,最开始做的是黑白喷印产品,我见证了它的发展历程。毫无疑问,目前最热门的业务就是织物喷印。”

Silicon edge graphics are the most popular application currently because retail establishments can change out the graphic every month or every three months and they don’t require a special company to come and make the switch. Any employee can switch out the silicon edge graphics. Airports, train and bus stations, sports venues and auditoriums have all moved in this direction.

硅边缘图像是目前最受欢迎的应用产品,因为零售机构每个月或每三个月都可以更改图文信息,并且他们不需要特定公司来更换其图文,任何员工都可以变换硅边缘图文信息。机场、火车站、汽车站、体育场馆和礼堂等都在朝着这个方向发展。

The graphics they want to hang around their venues are usually so large that printed vinyl just wouldn't work. They are too heavy to hang from the ceiling. Fabric makes that side of things much easier, says Michael Maxwell, senior manager marketing and business development at Mimaki USA, Inc. in Atlanta.

亚特兰大Mimaki公司市场营销高级经理迈克尔·麦克斯韦说,安装在现场的图像通常都很大,而乙烯基产品就不适宜做此项目,它们太重而不能悬挂在天花板上,织物产品则可以很容易地完成这个项目。

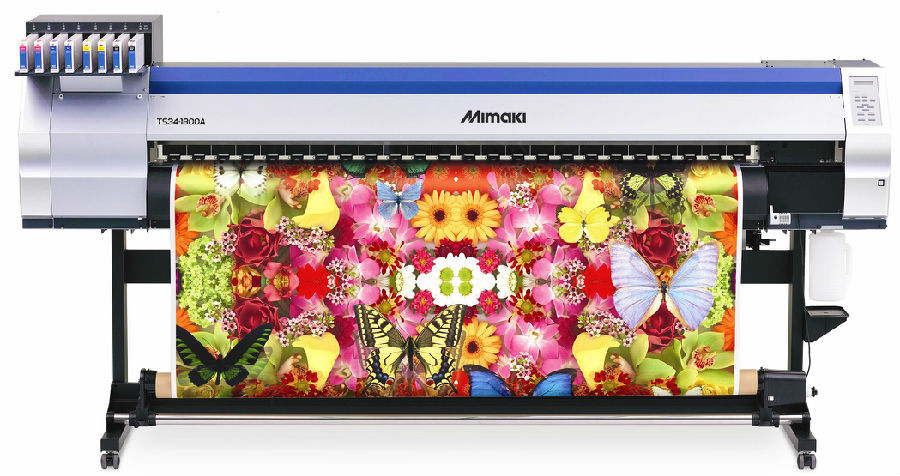

The move to SEG is making it hard for sign shops that rely on installation charges or bucket truck rental fees to make ends meet, he says. Mimaki is uniquely positioned in the grand-format textile printing industry because it offers all of the different textile printing techniques, including sublimation, solvent, UV curable and textile pigment.

他说,开展SEG业务使得标识商铺依靠安装费用或卡车租赁费用难以维持生计。Mimaki公司在宽幅纺织喷印领域处于独特地位,因为它提供所有不同的纺织喷印技术,包括升华、溶剂型、UV固化以及纺织染料技术。

The company assesses each client’s business to make sure the printer chosen fits the 80/20 rule. If 80 percent of a shop's business is geared toward one product line, they should purchase the printer that helps them achieve that.

该公司会评估每个客户的业务,以确保其喷印机的选择符合80/20规则。如果商铺业务的80%都是面向同一条产品线,那么他们就应该购买能帮助其实现这个目标的喷印机。

“If they are coming from a cut vinyl traditional, very small printing scenario, then they should look at solvent and latex where those two give them the ability to continue to manufacture on vinyl and things they are comfortable with,” Maxwell says. “If they are coming from textile sublimation, display graphics and backlits, then they’ve already got stuff in place that would give them the ability to branch into vinyl graphics.”

麦克斯韦说:“如果它们是传统很小的喷印产品,那么他们应该考虑使用溶剂型和乳胶这两种油墨,它们可以继续在乙烯基上作业;如果它们是织物升华、显示图文和背光产品的话,他们就能够随时用现有油墨进行乙烯基喷印。”

He points out that there isn't just one answer to the question of what type of printer to buy.

他指出,对于购买何种类型的喷印机,答案不止一个。

If a large sign shop would like the flexibility of being able to print trade show graphics, they should look at UV curable, solvent or latex technology “to give them that flexibility to go into soft signage and [continue to] manufacture things that are at the core of their business,” Maxwell says. “We’re able to steer customers in many different directions, not just funnel them into one specific technology.”

麦克斯韦说:“如果大型标识商铺想要使得喷印贸易展览图文更加灵活,他们应该考虑UV固化、溶剂型或乳胶技术,这些技术可以让他们更灵活地进入软性标识领域,[继续]经营他们的核心业务。我们可以引导客户向不同的方向发展,而不只是局限于一项特定技术。”

When a company moves into grand-format textile printing, it means they can produce more at a faster speed. If the company is printing mostly flags, they can use the grand-format textile printer to double up on the print orders, meaning they can print three to four times faster than smaller machines.

当公司进入宽幅喷印领域之后,就意味着他们能以更快的速度生产制作。如果公司主要是喷印旗帜,那么他们可以使用宽幅织物喷印机使得订单翻倍,这意味着它们比小型设备的喷印速度快三到四倍。

Shops also need to align with a company that doesn't just sell them a printer.

商铺还需要与那些不卖给他们喷印机的企业结盟。

“There's a lot that goes into being able to produce … good color consistently, roll to roll, batch to batch, job to job,”says EFI's Wozny.“That provides a significant competitive advantage once you have that knowledge. The quicker you have that, the quicker you have a competitive advantage in the market.”

EFI公司的瓦兹尼说:“许多商铺都想要生产具有色彩一致性、卷对卷的产品,一旦你掌握了这项技能,你就会有一个显著的竞争优势。你掌握地越快,你在市场中越快拥有竞争优势。”

He adds that shops should not ignore the finishing side of the business.

他补充道,商铺不应该忽视业务的进一步加工。

“When you are printing 8,000 square feet per hour, you can produce quite a large amount of material,” he says. That means shop owners need to spend just as much time investigating the backside options as they spend looking into which textile printer to buy.

他说:“当你以每小时8000平方英尺的速度喷印时,你可以生产大量的材料。这就意味着,商铺负责人需要与做调查花费同样多的时间,来仔细研究购买哪种织物喷印机。”

The margins in grand-format are still fairly healthy because not everyone is doing it, Wozny says. As long as companies utilize their grand-format machine 10 to 15 percent of the time, they can still make money.

瓦兹尼说,宽幅喷印领域的利润还是相当可观的,因为并不是所有人都在做这类业务。只要公司花10%到15%的时间来使用宽幅喷印设备,他们就能赚到钱。

“We were one of the early ones to get into this market and help drive its acceptance,” says Wozny. “With our purchase of Reggiani, we see this as a significant market opportunity.”

瓦兹尼说:“我们是最早进入该市场的企业之一,并且推动了它的发展。在购买Reggiani设备之后,我们将其看做一个巨大的市场机会。”