James Cross is North American product manager at AdamsTech located in Boulder, Colorado, distributor of the SDS ChannelBender Series machines throughout the Americas.

James Cross担任科罗拉多州博尔德AdamsTech公司北美产品经理,它是整个美洲SDS ChannelBender系列设备的分销商。

Though not always called "channelletters," fabricated or illuminated letters have been with us for nearly 100 years. Adolph Gast applied for the first patent for an illuminated letter on December 26, 1924. Since the 1920s, a seemingly limitless number of channel letters have been built using a variety of tools, materials, and techniques, but one thing is certain: illuminated letters have come a long way in what has been nearly a century of evolution.

尽管不总是被叫做“槽形发光字”,装配式或照明的发光字已经伴随我们将近100年了。1924年12月26日,阿道夫·盖斯特申请了第一个发光字专利。自20世纪20年代以来,用各种工具、材料和技术已经制作了大量的槽形发光字,但是有一件事是肯定的:发光字的发展已经走过了漫长的道路,将近一个世纪的进化演变。

Change is Slow

发展变化缓慢

Historically speaking, change has come about as a slow process inspired by creative artistic vision and facilitated by gradual improvements in materials and technologies. Generally speaking, groundbreaking innovations in channel letters and their fabrication have been few and far between. However, a handful of innovations introduced in recent years have been so paramount that nearly every sign manufacturer has had no choice but to adopt them in order to remain competitive.

从历史的角度来说,通过材料和技术方面的逐步改进和创造性的艺术眼光,改变发展发光字是一个缓慢的过程。一般来说,槽形发光字行业的突破性创新以及它们的制作方式少之又少。然而,近年来该行业推出的少数创新形式如此宝贵,以致于几乎每个标识制作商别无选择,只能采取这些方式来保持竞争力。

Old-school channel letter fabrication was a time consuming, cumbersome, laborious process of template making, measuring, notching and bending, nearly all of which was done by hand or with manually operated hand tools. For decades, a jigsaw was about the only power tool used in the channel letter building process. Essentially each letter or logo was a custom, one-off piece of fabricated art representing the blood, sweat, tears, arthritis, and carpal tunnel of a skilled craftsman.

老式的槽形发光字制作是一个耗时、繁琐、费力的过程,其中包括模板制作、测量、刻凹痕和折弯过程,几乎所有的制作都是徒手或用手动的工具完成。几十年来,用在槽形发光字制作过程中的唯一电动工具就是镂花锯了。基本上每个做成的发光字或商标,都代表着一个熟练工匠忍受着鲜血、汗水、泪水、关节炎以及腕管综合征,定制的一次性制作艺术。

The Old-School Process

老式发光字制作

For about 50 years, the fabrication process went as follows: a template would be drawn on paper and traced onto sheet metal, which would then be cut by hand to make the back panel of a letter using a jigsaw, scroll saw, or even hand shears. Then the wall of the letter would also be formed with heavy paper, the bending locations marked on the paper, and then the markings were transferred to a flat strip of metal, so the fabricator could identify the location of sharp corners, straight sections, gradual curves, and small, tight arcs on the wall of the letter, which is known as the “return.”

近50年来,发光字制作过程大致如下:在纸上画出模板,将其放置在金属板上,该金属板之后要用手切成字母的后部支撑板,字母用镂花锯、曲线锯或用手来切割成形。然后字母的槽壁也要用厚纸制作,在纸上标出折弯的位置,然后标记位置被转移到平坦的金属上,因此制作商可以识别出字母槽壁上尖角位置、直线部分、曲线部分和小弧形。

Once the return was marked, the fabricator could finally begin the tedious, manual process of shaping and forming signs and letters. Typically, sharp angles were bent one at a time using a hand brake or finger brake, then curves or arcs were formed using a number of different tools or jigs, depending on the fabricator’s preference.

一旦这些位置被标记好之后,制作商就可以开始乏味的手工标识、字母成型过程。通常是用手闸一次折弯一个棱角,然后根据制作商的偏好,用许多不同的工具或夹具来做出曲线形或弧形。

A few common tools used in forming curved sections of channel letters included “pipe trees,” or specially designed bending tables. Pipe trees were stands that were usually fabricated in-house that contained what resembled tree branches. The "branches" were made from various diameter steel pipe which the fabricator pushed the material against to create smoother, more consistent curves of different radii in the letter return.

几种常见的用于制作槽形发光字曲线部分的工具包括“管树”或专门设计的折弯台面。管树通常是用于室内的架子,包含像树枝一样的分支。这些“分支”是由各种直径的钢管做成的,制作商将其制成更光滑、更一致的不同半径曲线的字母。

Other fabricators preferred to use a bending table with either vertical metal spindles of different diameters, or metal pipes of various sizes which stowed one inside the other. When needed, the fabricator would telescope the appropriate diameter pipe outward and form the curve by working the material against the pipe.

其他制作商倾向于使用折弯台面做成不同直径的垂直金属轴,或一个套一个的各种尺寸金属管。在需要时,制作商会将外面的管子压缩成适当的直径,然后在管子上做出曲线。

Bending and notching of the “flange,” which was used to connect the wall of the letter with the back panel, was also done by hand. These notches numbered in the dozens—if not hundreds—per letter, depending on its size. Needless to say, this was quite an arduous task. Regardless of a channel letter fabricator’s preferred tools and methods, the process was almost entirely manual, and therefore agonizingly slow and costly for both the sign company and the sign client.

边缘折弯和切割的作用是将字母槽壁和后部支撑板连接起来,同样是徒手完成。每个字母上的切口如果不足一百个,就根据它们的尺寸进行编号。毋庸置疑,这是一个相当艰巨的任务。不管槽形发光字制作商的首选制作工具和方法是什么,其制作过程几乎完全是手动的,因此制作十分缓慢,且对标识公司和客户来说成本都极高。

The Modern Era

现代发光字制作

The mid-1990’s introduced the first truly groundbreaking advancement in the fabrication of channel letter returns in about a half century: automation. The first machine designed and built exclusively for the automation of bending channel letters was the Accu-Bend machine from Computerized Cutters Inc (CCI). The Accu-Bend went on to become the industry benchmark in the sign industry for a number of years.

20世纪90年代中期,经过大约半个世纪的时间,槽形发光字制作行业取得了真正突破性进展:自动化。Computerized Cutters Inc (CCI)公司的Accu-Bend设备,是第一台专门为槽形发光字自动折弯过程设计和建造的。Accu-Bend设备也成为多年来标识行业的行业标杆。

Shortly after the introduction of the CCI machine, a company called Arete was formed. Arete operated under a very different business model. Rather than a single, integrated channel letter solution like Computerized Cutters' Accu-Bend, Arete offered several different machines, each of which performed an individual task, thereby offering a more affordable, a-la-carte alternative to channel letter automation. For example, a customer could purchase an Arete machine that only performed the task of notching of the channel letter. The customer could later add a trim cap machine, or a flanging unit. Many sign shops found this more economical, piecemeal approach to be quite attractive from a capital investment perspective. Arete did well for a number of years until the company was dissolved in 2010.

在CCI设备推出后不久,Arete公司成立。Arete以一种极其不同的商业模式运营。与Computerized Cutters的单一集成槽形发光字折弯设备Accu-Bend不同的是,Arete供应几种不同的设备,每个设备执行一个单独的任务,从而为槽形发光字自动化提供更实惠、有针对性的选择。例如,客户可以购买一台专门用于切割槽形发光字的Arete设备,之后也可以添加一个封盖设备或翻边装置。从投资的角度来看,许多标识商铺发现这种更经济分散的方式相当具有吸引力。Arete公司在2010年解散之前的很多年都发展的很好。

Later, around 2005 a company called CLN of South Florida introduced two machines for the automation of channel letters. One would notch and flange the coil material, and the second machine could be programmed to bend the already notched and flanged material.

之后在2005年,南佛罗里达一家名为CLN的公司引进了两台槽形发光字自动化设备。一台设备可以对卷材进行切割和装凸缘过程,另一台设备则用来折弯已经切割和装好凸缘的材料。

Around 2007, the South Korean company named SDS introduced their ChannelBender brand machines to the sign industry for the notching, flanging, and bending of traditional channel letters as well as Trimless channel letters. SDS had previously established automated metal bending expertise in 1995 with machines designed for other applications, so the move to channel letter forming machines for signage was a natural progression. AdamsTech is the exclusive distributor and technical support provider for the SDS Easy Bender and ChannelBender Series machines throughout the Americas.

大约在2007年,韩国一家名为SDS的公司引进了标识行业ChannelBender品牌设备,用于传统槽形发光字和无边槽形发光字的切割、装凸缘以及折弯过程。SDS公司此前在1995年推出自动化金属折弯技术和为其他应用设计而成的设备,因此发展成为槽形发光字成型设备是一个自然而然的过程。AdamsTech公司是SDS公司Easy Bender和ChannelBender系列设备在整个美洲的独家经销商和技术支撑提供者。

Lighting Options Through the Years

多年来的照明选择

From the 1930s through the mid-1990s the only lighting options available for signage were neon, incandescent, or fluorescent. The limitations of these channel letter illumination solutions available at the time dictated the size and depth of channel letters for decades. Typical letters were 4” to 8” deep and about 16” tall or taller.

从20世纪30年代到20世纪90年代中期,可用于标识照明选择的只有霓虹灯、白炽灯和荧光灯。几十年来,这些槽形发光字照明选择的局限性决定了发光字的尺寸和深度。一般情况下,字母都是4英寸到8英寸深、16英寸高或更高。

Then along came LED technology which spawned another groundbreaking revolution in channel letters. LED technology began developing in the mid-20th century, but it wasn’t until after the year 2000 that LED illumination truly became a serious rival to traditional lighting methods. Since that time LED technology has evolved about as rapidly as that of the microprocessor. LEDs have become smaller, more effective, more versatile, lighter, brighter, less expensive, and more reliable.

随之而来的LED技术是槽形发光字另一个突破性进展。LED技术在20世纪中期开始发展,但直到2000年之后,LED照明才真正成为传统照明方式的劲敌。从那时起,LED技术的发展就和微处理器的发展一样快。LED变得更小、更高效、更通用、更轻便、更亮、更便宜、更可靠。

Today, this reliable, long-lasting light source can produce a broader range of colors with much greater consistency and a much improved accuracy of light dispersion. Today's customers look for smaller, sleeker, low-profile letters, and sign manufacturers are simultaneously looking for anything to make their operations more efficient, while also reducing costs. Longer burning LEDs, and smaller, lighter letters all mean lower shipping and packaging costs. Warranty and maintenance costs are likewise reduced by the longevity of LED lighting.

现如今,这种可靠持久的光源可以产生更宽范围的颜色,这些颜色有更高的一致性和改进的光弥散精确度。如今的客户寻求更小、更时尚、低调的发光字,同时标识制作商也在寻找提高运营效率、降低成本的方式。发光更持久的LED和更小、更轻的发光字都意味着更低的运输和包装成本。LED的寿命同时也降低了保修和维护成本。

Efficiency = Profitability

效率=利润

Sign manufacturers today are under tremendous pressure to be exceptionally efficient in everything they do in order to compete in what is now a global marketplace for channel letters. Lean manufacturing technologies and processes are essential to sign companies’ profitability and ultimately, their survival.

为了使得产品的性能超常高效,从而能在槽形发光字全球市场中极具竞争力,标识制作商目前承受着巨大的压力。高效的制作技术和过程对标识企业的盈利能力和生存来说是极其重要的。

Universally, they are finding that the now antiquated bending machines that have served them well for 10 or 15 years are significantly slower and less efficient than new channel letter forming machines that use more modern technologies, advanced engineering, and more precise manufacturing tolerances.

通常情况下,他们发现用了10到15年的老式折弯设备,与那些采用更现代化技术、更先进工程和更精准制造公差的新型发光字成型设备相比,其速度和效率都明显地下降了。

For example, old bending machines would waste three or more inches of material per letter, whereas some new bending machines using more modern technology have reduced waste per letter significantly by reducing waste to as little as 1/4” of material. This may not sound significant, but for shops turning out a few hundred letters every day, the savings is huge.

例如,老式折弯设备会浪费每个字母三英寸或更多的材料,而一些使用更现代化技术的新型折弯设备只会浪费每个字母1/4英寸的材料。这听起来或许差得不多,但是对商铺来说,每天制作几百个字母的话,节省下来的材料就会有很多。

Some modern bending machines produce output that is so much more accurate that hand finishing labor has been reduced by 30 to 40 percent relative to early generation automatic benders. Older machines simply can’t bend stainless steel with any degree of accuracy. Some of today's higher-end machines can even process unforgiving materials like #8 polished stainless steel, as well as increasingly popular Trimless materials.

相对于初代自动折弯设备,一些现代折弯设备产生的输出更准确,以致于徒手加工劳动减少了30%到40%。老式设备无法折弯任何准确度的不锈钢,而一些现代高端设备甚至可以处理棘手的材料,像#8抛光不锈钢,以及越来越流行的无边材料。

Trimless Materials

无边材料

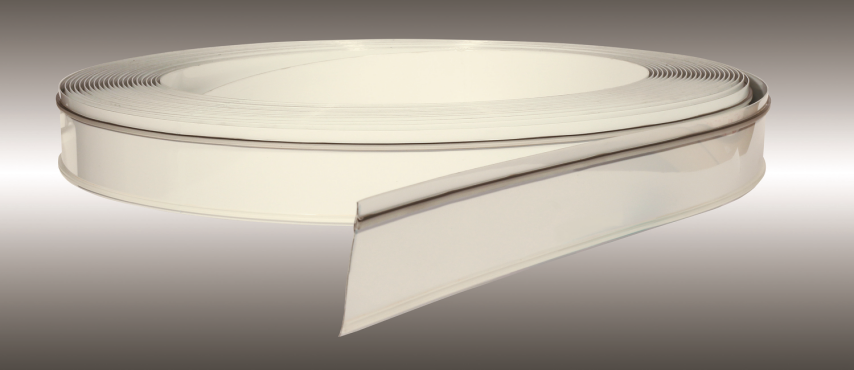

These Trimless materials can eliminate the need for the trim cap, which has been used to attach the letter face to the letter return for decades—and everyone despises working with it. These new Trimless technologies allow sign companies to produce cleaner-looking letters faster and more efficiently than old-school trim capped channel letters.

几十年来,这些无边材料消除了封盖的需要,封盖的作用是将字母表面贴在字母折弯部分,没人愿意做这项工作。这些新型无边技术使得标识企业能够更快更高效地制作表面更洁净的发光字。

The win-win for manufacturers is the fact that Trimless letters are seen as a premium product and can therefore command a premium price, regardless of the fact that the costs to produce them are the same or even less than traditional letters. Lastly, modern bending machines have a much smaller footprint than the larger earlier units from the mid-'90s. Today’s fully automatic machines require an entire working area as small as 6’× 12’.

无论生产无边发光字的成本与传统发光字一样还是更低,将其当做高端产品、定为高价格就是制作商之间的双赢局面。最后,现代折弯设备比90年代中期大型设备的工作区域小得多。现今的全自动设备的整个工作区域仅需6英尺×12英尺。

Even the trim cap process has been successfully automated to a degree. Though many have tried and failed at manufacturing a trim cap processing machine that actually works, there are one or two that work quite well. For example, the Easy Trimmer from SDS/AdamsTech processes trim cap extremely quickly. This kind of performance goes a long way toward eliminating the bottlenecks that occur at the trim cap station of nearly every sign manufacturer around the world.

就连封盖过程都已经实现了自动化,尽管许多人都尝试制作封盖加工设备,但是做成的只有一个或两个。例如,SDS/AdamsTech的Easy Trimmer封盖处理设备就非常迅速。这种性能在很大程度上消除了世界各国标识制作商在封盖处理方面遇到的瓶颈。

Signs and channel letters in particular have become such an integral part of people’s daily lives, that many people outside the industry simply take for granted the role channel letters play in helping customers find their way, and identify the business or destination they are trying to locate. From the largest professional sports stadiums and big box stores to the local dry cleaner, bistro, veterinarian, or post office, people have come to depend on channel letters to help them find and identify buildings, businesses and shopping centers they frequent throughout their daily lives. Likewise, businesses have come to trust their corporate identities to signs and logos manufactured as channel letters. The law of the jungle is the survival of the fittest, and the key to staying fit for sign manufacturing companies is to improve manufacturing techniques, invest wisely in new, more efficient equipment, and utilize innovative materials and processes that help make their products stand out.

标识和槽形发光字已经成为人们日常生活中不可或缺的一部分,许多标识行业外的人只是理所当然的认为槽形发光字的作用,就是帮助客户找到他们要走的路,确定他们想要到达的目的地。从最大的专业体育场和超级广场,到当地干洗店、小酒馆、兽医诊所或邮局,人们都是依靠槽形发光字来帮助其确定目的地的。同样地,企业也是将标识和商标做成槽形发光字来表明身份的。弱肉强食,适者生存,标识制作商保持健康发展的关键,就是改进制作技术、明智地投资新型高效设备、使用创新性材料和处理过程,从而使其产品脱颖而出。