The LED boom for new cabinet sign production is here. The signage industry has enjoyed the advantages of using LED in channel letters for years. However, until recently, using LEDs in a cabinet sign just did not make financial sense.

新型灯箱标识中LED的繁荣发展就在眼前。在槽形发光字中使用LED照明技术已经风靡了多年,标识行业公司从中获取了很多好处。然而,直到最近,在灯箱中使用LED照明技术才有了实际意义。

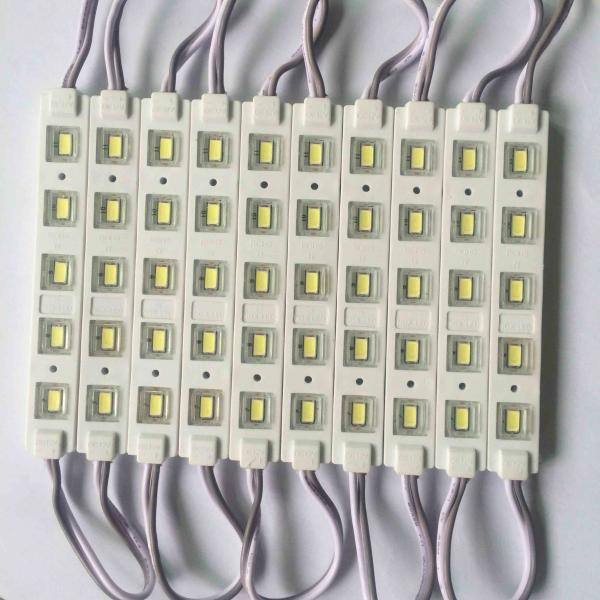

Traditional LED chain modules, like those used in channel letters, have limitations in sign cabinet applications. The install process is lengthy to layout, tape, and glue each and every little module. The high labor and component cost of using traditional channel letter LEDs has been a road block for general acceptance of LEDs as a suitable light source for cabinet signs.

传统LED链模组在灯箱应用中有一定局限性,譬如那些用于槽形发光字中的LED模组。其安装过程是冗长的,需要把所有小模组布局、捆扎,然后粘合在一起。高劳动力成本和使用传统槽形发光字LED组件的成本,已经阻碍了LED成为灯箱标识中合适的光源。

The good news is that everything has changed! Today, sign manufacturers using proper LEDs specifically designed for sign cabinets enjoy substantial advantages over sign manufactures continuing to use fluorescent or standard LED chain modules.

好消息是一切都改变了!现如今,使用专门用于灯箱标识中LED的标识制造商比那些使用荧光或标准LED链模组的标识制造商享受到了更加实质性的好处。

Simpler and Less Costly

更简便、更便宜

Sign manufacturers using high performing box sign LEDs are winning more projects, increasing margins, increasing production capability and simplifying manufacturing and purchasing processes. Even more importantly, the appropriate LED allows sign manufacturers to sell LED cabinets at a price comparable to fluorescent signs.

使用高性能的灯箱标识LED的标识制造商赢得了更多项目、增加了利润、提高了生产力、简化了制作过程和采购流程。更重要的是,合适的LED使得标识制造商销售LED照明灯箱的价格与荧光照明灯箱的价格具有可比性。

Box sign LED modules, while considerably less costly than traditional LED modules, may in fact be less costly than fluorescent. The following example with a 4’ x 8’ sign cabinet will illustrate how a box sign LED lighting solution can be competitive versus traditional LED and fluorescent using the following design concepts.

灯箱标识中的LED模组与传统LED模组相比,其成本大大地降低了,事实上可能比荧光照明的成本更低。下面的例子中是一个4英尺×8英尺的灯箱标识,接下来会为大家说明,参照以下设计构思的灯箱标识LED照明方案,如何能够与传统LED和荧光照明方案相媲美。

Minimize the Number of Modules

最小化模组数量

One solution to reduce lighting installation time is to minimize the number of modules required to evenly and brightly light a cabinet face. A 4’ x 8’ cabinet only needs 15 modules (three rows of five) for both single and double-sided cabinets using LED modules specifically designed for sign cabinets. In contrast, a standard LED chain module with six-inch pitch (module to module spacing) would require approximately 105 modules in single-sided cabinet and 210 modules in a double-sided cabinet.

缩短安装时间的一种方案是将均匀照亮灯箱表面所需的模组数量最小化。一个4英尺×8英尺的灯箱只需15个模组(三排,每排5个),因为单面和双面灯箱使用的都是专门为其设计的LED模组。相反地,对于标准6英寸(模组之间距离)LED链模组,单面灯箱需要大约105个,双面需要210个。

The lighting installation time is greatly reduced using a box sign LED system. Traditional channel letter LED installation takes much longer considering that you need to measure, lay out the modules, peel tape and mechanically fasten or silicone each tiny module into place. Using a reduced number of box sign LEDs provides an approximate 80 percent reduction in lighting installation time in a 4’ x 8’ sign cabinet, lighting a 4’ x 8’ sign in about 15-20 minutes.

使用灯箱标识LED系统之后,大大缩短了安装时间。传统槽形发光字LED的安装时间更长,因为你需要测量、为模组布局、剥胶带,还要机械地将每个小模组固定住。灯箱标识中使用的LED数量减少之后,会缩短4英尺×8英尺灯箱约80%的安装时间,可以照亮4英尺×8英尺灯箱大约15-20分钟。

Box sign LED modules that are double sided offer greater advantages over traditional LED modules. Lighting a double-sided cabinet with traditional LEDs requires double the amount of LEDs compared to a single-sided box. Doubling the number of LEDs also directly doubles the required amount of labor to finish the cabinet. On the other hand, using box sign LED modules in a double sided box sign still only requires the same 15 modules with about 20-30 minutes of labor time.

用于双面灯箱标识的LED模组比传统LED模组能提供更大的优势。照亮一个双面灯箱所需的LED数量是单面灯箱所需数量的二倍。LED数量翻倍直接导致完成灯箱安装工作的劳动力翻倍。相反地,双面灯箱中只需使用15个灯箱标识LED模组、20-30分钟的劳动时间就可以完成。

Utilize a Snap-Track System

使用瞬时跟踪系统

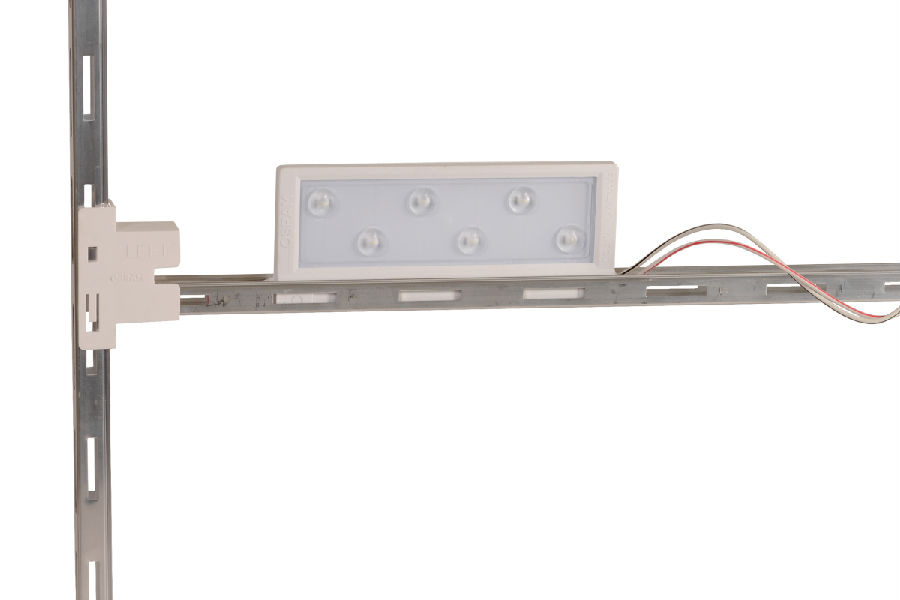

Snap-track systems provide greater time savings when installing your LED lighting system in both single- and double-sided sign cabinets.

安装单面和双面灯箱标识的LED照明系统时,使用瞬时跟踪系统可以节省更多时间。

The snap track completely eliminates the need to peel tape, silicone and/or mechanically fasten the modules into place. The modules compress into the track and click into place with the squeeze of your hand. No more rivets, screws, silicone, tape peels or wasted time.

瞬时跟踪系统完全消除了剥胶带、机械地固定模组过程,直接用手将模组折叠起来并压进凹槽中。没有多余的铆钉、螺钉、硅胶、胶带皮或浪费时间的工序。

The snap track allows for very quick row spacing adjustments to accommodate specific project requirements. To make quick adjustments, simply unclick, relocate, and click the track into its new position.

瞬时跟踪系统使得调整行间距速度更快以适应特定项目的需求。它可以实现迅速调整、简单反选、重新定位并跟踪到其新位置的功能。

Use Brighter Modules with Advanced Optics

使用高等光学照明模组

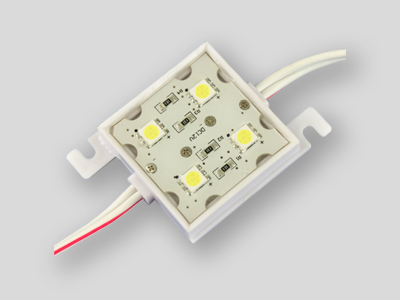

The use of fewer modules is made possible by significantly increasing their brightness. The module must also use a superior optic to spread the brighter light uniformly over a wider area of the sign face. The optic is the key feature that allows brighter modules to be spaced further apart. Without an enhanced optic, there would be hot spots and shadowing.

通过显著增大亮度可以使模组数量最小化成为可能。模组也必须使用高等光学透镜在标识正面形成更大的照明区间。光学透镜的关键特性是允许照明模组间距进一步加大。没有增强型光学透镜,就会产生潜在的危险区域和阴影。

LED Must be Competitive with Fluorescent

LED必须与荧光照明有竞争力

Box sign LED solutions have already proven to be significantly more advantageous than traditional LED chain modules when it comes to lighting a sign cabinet. However, depending on how many signs your shop builds, box sign LED lighting systems can actually rival the manufacturing cost of using fluorescent and, in some cases, may actually cost less.

在灯箱照明中,已经证实了灯箱标识LED解决方案比传统LED链模组更有优势。然而,根据商铺生产标识的数量,灯箱标识LED照明系统的成本可以与使用荧光照明的制作成本相匹敌,在某些情况下,或许会花费更少。

There are a variety of costs associated with manufacturing sign cabinets. In order to evaluate the true cost and savings of lighting a sign cabinet with box sign LEDs it is imperative to consider all manufacturing costs.

制作灯箱标识包含各种各样的成本。为了估算使用灯箱标识LED的真实成本和能源节省总量,必须将所有的制作成本考虑在内。

Cost of Components

组件成本

Let’s start by looking at the cost of components for a 4’ x 8’ sign, single- and double-sided for both fluorescent and LED cabinet sign systems.

我们先来看看一个4英尺×8英尺灯箱所有组件的成本,包括单面和双面的荧光照明以及LED照明灯箱。

• Fluorescent Components—Keep in mind that the costs are the same for single- or double-sided applications. Four pairs of sockets, four 8’ lamps, one electronic ballast, plus raceway aluminum, wires and connectors.

·荧光照明组件——注意,单面和双面灯箱应用的成本是一样的。四排插座、四个8英尺照射器、一个电子镇流器,再加上铝电缆管道、电线和连接器。

• Box sign LED Components—To light a double-sided cabinet you will have an increased module cost by switching from single- to double-sided modules. Additionally, there are track, connectors and an additional power supply that will add to the component cost. Again, the module count stays the same at 15. Fifteen modules and one power supply (add five tracks, three pairs of connectors, and a power supply for double sided cabinet)

·灯箱LED照明组件——为了照亮双面灯箱,要将单面模组转换成双面模组,这样其成本就会增加。此外,跟踪系统、连接器和额外的电源也会增加组件的成本。同样地,模组数量仍然是15个。十五个模组和一个电源(加上五个追踪系统、三对连接器、以及一个双面灯箱电源)

I invite you to do a little calculation of your component costs for your personal reference. For a single-side box sign, the LED components may cost a little more than the fluorescent components. The component cost of fluorescent is clearly less than a double-sided LED solution. Keep in mind that the component cost is only one aspect of production cost. We must look at labor as well.

我请你做一个简单的供你个人参考的组件成本计算。对于单面灯箱标识,LED照明组件可能比荧光照明组件更贵一点。而荧光照明组件的成本显然比双面LED照明组件低。注意,组件成本仅仅是生产成本的一部分。我们还要考虑劳动力成本。

Cost of Labor

劳动力成本

Now let’s compare labor costs. I believe the LED option offers a substantial labor reduction when compared to fluorescent.

现在我们来比较一下劳动力成本。我认为与荧光照明相比,LED照明的劳动力会大幅下降。

• The fluorescent labor time will come from designing, measuring, cutting, bending and installing raceways. Furthermore, there is punching and wiring sockets and installing the lamps. It can take three to four hours to design, produce and install every component of a fluorescent lighting system in a 4’ x 8’ cabinet.

荧光照明劳动时间主要花费在设计、测量、切割、折弯和安装电缆管道上。此外,还有钻孔和接插板以及安装照射器的工作。通常会花费三到四个小时来设计、生产和安装4英尺×8英尺灯箱上的每个荧光照明系统。

• The LED solution should take about 15-25 minutes for a single-sided sign, and about 20-30 minutes for a double-sided one. Labor savings using LED is substantial and can add up to significant savings.

·在单面灯箱上安装LED照明系统会花费15-25分钟,在双面灯箱上大约需要20-30分钟。使用LED照明方案会节省大量劳动力,其节省总量是惊人的。

Increased Profits Through Faster Production

快速生产增加利润

Sign manufacturers routinely over-emphasize component cost when comparing LED systems with fluorescent systems and often choose fluorescent simply because the component cost is $50-$150 less. However, the amount of labor saved by choosing LED could negate that $50-$150 component cost difference.

将LED照明系统和荧光照明系统作比较时,标识制造商通常都会偏重组件成本,并且常常会选择荧光照明系统,因为其组件成本比LED照明系统少了50-150美元。然而,选择LED照明系统节省的劳动力成本刚好抵消了50-150美元的组件成本。

Sign manufactures should place more emphasis on increasing profitability by increasing production rates. Let’s imagine that a sign company profits $500 on every 4’ x 8’ sign that it can push out its shipping doors. Using fluorescent, one skilled laborer could install lighting in three 4’ x 8’ box signs during the course of one eight hour workday. At this rate, the sign company is limited to shipping out three signs and will average about $1,500 for that day.

标识制造商应该更加重视通过提高生产率来增强盈利能力。假设一个标识公司输出一个4英尺×8英尺灯箱可以获利500美元。如果使用荧光照明系统,一个技艺娴熟的工人可以在八小时工作日内,完成三个4英尺×8英尺灯箱的安装工作。以这种安装速率来计算的话,该标识公司一天只能输出三个灯箱,平均获利1500美元。

Using LED, that same employee can now install lighting into 10 signs and enjoy a 15-minute break in between each install project. Furthermore, the same sign company can ship out 10 signs and make $5,000 that day. Moving from fluorescent to LED has increased the sign company’s daily profit by $3,500. Continuing to use fluorescent in this case actually stalls production and costs the sign company $3,500 per day. The appropriate sign cabinet LED can simply be more profitable than using fluorescent.

如果使用LED照明系统,同一个工人一天内可以安装10个灯箱,完成一个灯箱之后,还可以休息15分钟。此外,同一家标识公司一天之内可以输出10个灯箱,获利5000美元。从荧光照明系统到LED照明系统,标识公司日利润增加了3500美元。在这种情况下,如果继续使用荧光照明系统,该公司每天会损失3500美元。合适的灯箱标识LED照明系统比使用荧光照明系统更有利可图。

The Results

结论

Sign manufacturers may not need to produce 10 electric signs per day, but it is clear that there are major benefits that sign companies enjoy by switching to LED for production. Using LED in cabinets frees up employees to work and complete other projects that will help bring in additional revenue. Often in smaller sign shops, the owner is also the sign manufacturer. Imagine how much more available time the owner has to go make sales calls, work on other sign projects and grow the business.

标识制造商或许不需要每天生产10个灯箱,但是使用LED照明系统来生产灯箱,标识公司从中获取的好处是显而易见的。在灯箱中使用LED照明系统可以解放工人的双手,使得他们可以完成其他项目,从而带来额外的利润。通常情况下,较小的标识商铺店主就是标识制作人员。想象一下,如果解放了该店主的双手,他会有多少时间来打销售电话、做其他标识项目、增加业务量呢?