One thing I have been focusing on in my car wrap workshops for both full print and color-change wraps the past year is ways of increasing quality and durability while lowering install times by 20 to 50 percent. Most people immediately think this is achieved solely through the installation portion of the wrap but it’s actually primarily achieved through good preparation.

在过去一年里,在全列印和变色车身贴制作方面,我比较关注的就是将安装时间降低20%到50%的同时,提升车身贴的质量和耐用性的方法。大多数人立即就会想到,只要安装过程做得完美就可以了,但是事实上,主要是通过充分的准备工作来实现。

Here are several simple rules for full print and for color-change wraps that will help increase your profits, and make for happy, faster wrap installers.

这里有一些关于全列印和变色车身贴制作规则,可以帮助商铺增加利润、使得安装过程更愉悦、迅速。

Receive the Vehicle the Day Before

提前一天接收车辆

This rule applies for both full print and for color-change wraps. Every installer or wrap shop has waited for clients to show up on the day of install (often times for hours). This delay on starting the wrap causes stress that leads to installers making mistakes as they try to get the job done by the end of the day.

这些规则适用于全列印和变色车身贴。所有安装人员或车身贴商铺都会在安装前一天(通常几个小时)等着客户出现,这就延迟了车身贴安装时间,会给安装人员造成压力,因为他们如果要在截止日期前完成安装,期间可能会出现工作失误。

If the vehicle is dropped off the day before then when the installers show up at 9 am the next morning the car is there at the proper temperature and is fully dry. This means they can get to work right away, or, with a color change, hardware can be removed from the car the day before so that installers can simply wrap instead of prep.

如果车辆在安装前一天到位,处于适当的温度且完全干燥的情况下,那么第二天早上9点,安装人员一上班就可以立刻开始安装车身贴。或者说,如果想要安装变色车身贴,可以在前一天将车辆上的硬件暂时拆卸下来,这样安装人员就可以不用做准备工作,直接开始安装。

Rules for Full-Print Wraps

全列印车身贴规则

#1 – Smart Designs

#1-巧妙的设计

Keep your wrap designs smart. An example of a smart wrap design, is the one made by Stephen Sinek that was used for the Avery Dennison/Mutoh School of Wrap workshops this year (see Image A). It’s a very cool design aesthetically that would satisfy the client and also works very well in terms of install.

保证车身贴有一个巧妙的设计方案。举个例子,今年用于艾利·丹尼森/武藤车身贴学院制作车间的车身贴设计地就很巧妙,是由斯蒂芬·西内克设计的(如图A)。从审美的角度看,这是一个非常酷炫的设计,一定会获得客户的肯定,并且安装也很简便。

The hood, roof and trunk don’t connect to the sides which makes them islands. The hood has to only be centered and straight, the text on the roof simply has to be made straight and there is no text or numbers on the trunk which means it’s just wrapped with no measuring required.

车辆的引擎罩、顶篷和后备箱部分贴膜的设计是独立于整个车身贴的。引擎罩必须居中且笔直,顶篷上的文字也必须是连续的,后备箱上没有任何文字或数字,这就意味着这些部分不需要测量就可以安装。

The front bumper has matching design elements to the rest of the overall design but they don’t literally connect to the front fenders which saves the installers huge amounts of stress and time.

前保险杠部分贴膜设计与剩下的车身贴总体设计是匹配的,但是它们与前挡泥板是没有关系的,这就节省了大量的安装压力和时间。

The driver and passenger sides are the same so the installers can reference both sides (once the first side is done there is no guessing where the second side goes). The Avery Dennison text on the doors is easy to measure as the bottom of the door is straight so it makes a great anchor to balance the wrap. The sides were also printed horizontally on 60" wide material so there is no need to register panels or apply a separate piece for the rocker panel which would be the case if it was printed on 54" wide material.

驾驶座一侧和副驾驶座一侧的贴膜都是一样的,因此安装人员可以以一侧作为参照进行设计(一旦有一侧设计完成,另一边就无需其他设计了)。车门上的Avery Dennison文字所在位置很容易确定,因为车门的底部是笔直的,因此它是协调车身贴的标准参照物,这些都是在60英寸宽的材料上横向打印的。

The back of the bull graphic goes from the rear fender to the back bumper. This would be very difficult to line up if the image had to be matched up with separate panels. However, this was avoided by printing the back bumper only in red. This means the back bumper is put on first and the back of the bull is applied as an overlay. It’s a connecting design without having to actually connect anything.

这个大型图文贴膜最艰巨的部分是从后挡泥板到后保险杠之间。如果图像是由好几块单独的面板拼成,那么就会很难将每块面板边缘对齐。但是,只将后保险杠喷印成红色就可以避免这种情况的发生。这就意味着要先安装后保险杠部分的贴膜,然后再做其他的。

#2 – Smart Layout

#2-合理的布局

What slows down installers the most is getting the registration right, and overlaps that pop out of recessed areas that can affect durability long terms if they are not properly post heated.

拖慢安装进程的最主要原因是需要将贴膜重合部位做好,因为凹陷部位的重叠贴膜,如果没有经过适当的加热后处理,就会影响贴膜的长期耐用性。

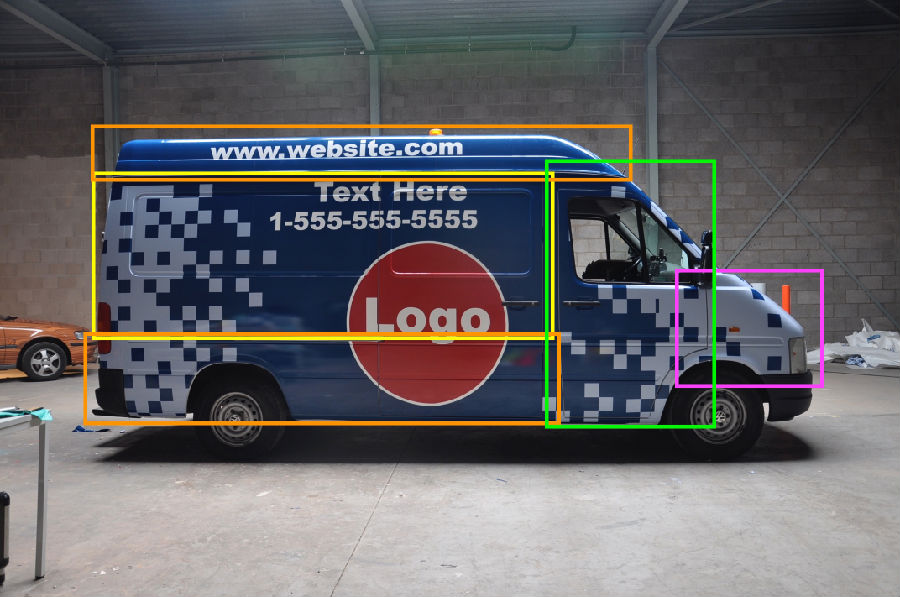

Based on this, it’s best to avoid making all the panels vertical (still the norm for vehicles like Sprinter vans). Instead, it’s best to use a combination of vertical and horizontal panels. In the illustration below (see Image B), the main panel on the back section bridges the recessed area which means no registration on those tricky areas. It also means that the overlaps are hidden in the recessed areas and will have zero stress as they will be fed in instead of bridges and pushed in.

在此基础上,最好避免将所有面板竖直放置。相反地,使用竖直和水平相结合的放置方式是最佳的。在下面的例子中(如图B),车尾部分主要面板填充了凹陷区域,即该位置没有难处理的贴膜重合部位。这也意味着重叠部位被隐藏在了凹陷区域,那么在填充时就无需桥接器来完成。

#3 – Choose the Right Material

#3-选择最佳材料

I went to around 40 wrap shops this year teaching workshops and often saw installers wrapping vans with deep recessed areas using the improper print and lamination combinations. This leads to longer installs as the installers have to often feed the material in these areas and often the wraps fail and have to be either fixed or replaced. The key is to use the most flexible combination—like Avery Dennison 1105 with 1460z or 3M IJ480. Using these materials might seem costlier (generally around 10% extra) but if it speeds up installs and insures no failures then it’s a bargain in the long run.

我今年参加了大约40家贴膜商铺的教学研讨会,经常看到安装人员用错误的喷印和层压组合方式来填充凹陷区域。这样就会导致安装时间更长,因为安装人员需要频繁地对这些位置进行填充,而且贴膜如果损坏,就需要修理或更换。避免产生这种情况的关键就是要使用最灵活的组合方式——比如艾利·丹尼森公司1460z型1105号材料或3M公司的IJ480号材料。使用这些材料可能会很昂贵(通常超出平时成本的10%),但是如果它能加快安装进程并且确保不会失败的话,从长远来看,它就非常划算了。

#4 – The Three-inch Rule

#4-三英寸原则

All designers should create a three-inch buffer for any important text and images from hot spots like door handles, lights, wheel wells and license plate areas. This buffer allows installers to adjust placement and avoid having to take extra time measuring. This year I visited a wrap shop where the installers were wrapping a Hummer H2 that had all the text about half an inch from all these hot spots (see Image C).

设计师都应该为所有较难处理区域的重要文本和图像预留3英寸的缓冲区,譬如车门把手、车灯、车轮和车牌位置。这个缓冲区方便安装人员调整位置,且避免了额外的测量时间。今年我到一家贴膜商铺参观,发现他们的安装人员为一辆悍马H2安装车身贴,贴膜上所有文本距离这些难处理区域只有半英寸(如图C)。

I asked the designer why he did this and his reply was, “I wanted to challenge the guys.” I told the installers that they should challenge the installer by putting his desk out in the parking lot on a 100-degree day. What the designer doesn’t understand is that by laying out the text this way it slowed down the install by 15% and ran the risk of a reprint if it didn’t fit. This is a risky move all around and is a quiet drain on profits for a wrap shop owner.

我问设计师这样做的原因,他说:“我想要考验一下安装人员。”我告诉安装人员,他们应该在100华氏度下的停车场里工作来应对这个考验。这个设计师不理解的是,这样的文本布局会将安装进程拖慢15%,如果贴膜不合适,就要面临重印的风险。这对整个安装过程来说是一个冒险的举动,对贴膜商铺店主来说其利润会流失。

Rules for Color-Change Wraps

变色车身贴准则

#1 – Don’t Over-Remove Hardware

#1-无需拆卸硬件

One big thing I pushed in my workshops this year was not over-removing hardware. Instagram and Facebook are filled with pictures of color changes that have the bumpers and head lights removed. These removals can take a long time, result in broken clips and lead to overwrapping. I show a variety of techniques in the workshops that demonstrate how to wrap these areas perfectly without hardware removals. The result looks exactly the same but the amount of time saved is astronomical, especially when you consider that the bumper doesn’t have to be removed a second time when the wrap is removed.

今年我在商铺中做出的一项重大决定是不拆卸硬件。Instagram和Facebook上所有关于变色车身贴图片都是将保险杠和车前灯拆卸下来。这些拆卸工作会花费很长时间,造成车身贴损坏以及需要进行外部包装。我在制作车间展示了各种安装技术,实现在无需拆卸硬件的情况下完美地安装车身贴。拆卸硬件和不拆卸硬件的最后安装结果看起来是完全相同的,但是不拆卸硬件节省的时间可以说是天文数字,尤其是在移除车身贴时,无需二次拆卸保险杠。

#2 – Let the Installers Just Install

#2-让安装人员仅做安装工作

There are a lot of mechanics in the world but not a lot of people who can wrap a bumper in one piece. If an installer removes hardware, cleans and cuts down the panels before a wrap they are tired when they begin wrapping, which is where the money is at.

世界上有很多技术人员,但是并没有很多可以将保险杠完好无损地安装好贴膜。如果一个安装人员将硬件拆卸、面板清洁和切割工作都做了,那么他在开始安装车身贴之前就疲惫不堪了,这就解释了高额成本都花在了哪里。

Hiring a mechanic for these tasks is more economical than paying an installer to remove the hardware. A mechanic can be taught to clean and cut down panels. This means the installers simply wrap, which lowers installer times dramatically. I have seen several wrap shops that employ this concept and it creates a very efficient workflow and quicker turnaround times.

雇佣一个做这些工作的技术人员比支付安装人员拆卸硬件的费用更合算,我们可以教会技术人员清洁和切割面板,这意味着安装人员只需进行安装工作,会极大地减少安装时间。我见过几个车身贴商铺都采用这一想法,并且都实现了非常有效的工作流和更快的周转时间。