For this month’s Shop Talk, we’ll look at a very simple sign project, but one that has significance for every sign shop that has limited means for welding aluminum, yet needs to make signs that are clean and professional looking and hide or minimize fasteners of any kind.

本文我们将通过一个非常简单的标识项目来讲述,如何在标识安装过程中隐藏紧固件。对于每个标识商店来说,焊接铝的手段都是有限的,要制作出一个干净而专业的标识,就必须掌握隐藏紧固件的多种方式。

This large 4’ x 8’ architectural sign, made from aluminum tubing and aluminum laminate sign face material, was fabricated using the most basic shop tools, and required no aluminum welding and almost no welding at all. The posts are secured without visible hardware, and the finishes are professional, or in the case of the faces factory applied.

在这个项目中,这块大型的4'×8'建筑标识是由铝管和铝合金表面材料制作而成,表面的处理非常专业,几乎没有可见的硬件显露,也几乎没有经过焊接步骤,当然,实际应用起来也是非常安全的。

Because aluminum laminate material lays very flat and has a durable factory finish, it is a favorite of sign makers today. But, having some thickness, unlike thinner prefinished aluminum sheet (.040 or .063), it is ideal for small counter-sunk fasteners. On this job the fasteners for the faces are exposed, but are so small and flush as to be almost invisible. Two faces back to back, sandwiching the framework, create a “stressed skin construction” that holds the sign together.

由于铝合金层压板材料的表面非常平整,具有耐用的外观,是当今标识制造商非常喜欢使用的材料之一。但是,与较薄的预制铝板(.040或.063)相比,不同的是,它具有一定的厚度,只适用于一些小型的紧固件。而在这个项目中,是将一个表面紧固件暴露的标识进行改装,虽然这个暴露的紧固件很小,可以说几乎看不见,但想要拥有一个完美的标识,即使细小的瑕疵,也是不被允许的,因此,他们在标识背对背的两面,用了一个框架,将标识夹在了一起。

The posts are aluminum square tubing, 4” x 4” in size, and the posts and their caps would get a durable powder coated finish in the end. But the actual internal frame parts would go unfinished, as the top of the sign is well above eye level, and the bottom edge below, and the ends will never be seen.

标牌柱子的尺寸是4”×4”的铝方管,并使用了粉末涂层。实际的内部框架部分是不完整的,因为标识的顶部远远高于人们的水平视线,下方的底部边缘将不会被看到。

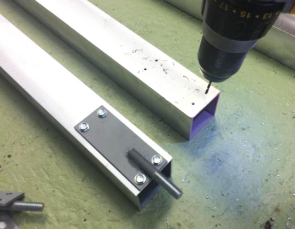

The posts were slotted on a wood cutting table saw, equipped with a fine-tooth carbide tipped blade. Studs of 3/8” diameter would secure the sign to the posts, so the groove we cut needed to be a bit over .375” wide. The slot or groove was cut slightly too long, and the posts would be trimmed to the exact length last. A tape mark on the posts and on the table saw were used to get the slot cut to approximately the right length.

当标牌柱子在木制切割台上,被精细碳化物刀片锯开以后,直径为3/8”的螺柱就可以将标识固定在支柱上了。此外,切割的凹槽需要超过3.75英寸的尺寸,可以使用柱子上的胶带标记切口切割的长度。

To slot the posts, a saw cut was first made in the exact center of each posts, and then the rip fence was moved over approximately 3/32” at a time, on either side of the saw cut. After a few passes, when a 3/8” diameter bolt would slide easily in the grove, that part of the job was finished.

值得注意的是,在每个柱子的中心要先确定好锯切,然后在切割锯的任意一侧进行移动,当移动到3/32英寸时,直径为3/8“的螺栓容易滑动时,该部分工作就算完成。

The internal framework, not welded at all but held together by the faces themselves, was made from 1.5” x 1.5” aluminum tubing with an .080 wall thickness, which is not expensive but plenty strong and rigid. These were cut on a miter box saw, which most shops would have. Four shop made fittings, two for each end, were made from a small strip of steel flat bar into which a hole was drilled near each corner. A 3/8” bolt, with its head cut off, was welded to each steel strip with the threads protruding about 1”. These fittings were screwed to the ends of the two long members, and turned toward the inside of the sign.

内部框架是不进行焊接的,由面部保持在一起,面部由厚度为.080的1.5“×1.5”的铝管制成,铝管经济适用,而且具有刚性。另外,在四组配件中,每组两个,由一小块扁平钢筋制成,这些配件被拧到两个长部件的端部,而且方向要朝向标识的内侧。标识每个角落都有一个钻孔,一个3/8“螺栓,螺栓的头部被切断,焊接到每个钢带上,螺纹需要突出约1”的长度。

The vertical members of the frame were cut to loosely fit between the long members and not attached to anything but the faces. Again, no welding would be needed, the critical measurement was that the long members were exactly 96” long to fit the faces perfectly.

接下来是将框架的垂直构件进行切割,然后放置在长构件之间,不依附到标识面部之外的任何东西。在这个过程中同样不需要焊接,但关键的测量长度需要达到96“才能适合标识面部。

The aluminum laminate faces sandwiched the four frame members together and some special rivets were used to secure everything together. These very low-profile rivets are made to be counter sunk, and lay really flat when installed correctly. After a hole is drilled, it is carefully countersunk, and the installed rivets seat down into the surface flush and smooth. When painted to match the face, these countersunk rivets are truly insignificant, and at any distance virtually invisible.

铝层压板将四组框架构件夹在一起,并使用了一些特殊的铆钉将所有东西固定在一起,这些不太引人注意的铆钉在正确安装时,需要平坦放置。在钻孔后,安装的铆钉下垂到表面,在与标识匹配好之后,几乎是看不见的。

Once the sign was assembled, the unpainted posts are put temporarily in place, and the exact top of the posts are marked, just short enough of the top of the sign to allow for a 3/16” thick post cap. After marking the posts, they were neatly trimmed on a metal bandsaw, but can be cut just as well using a miter box saw and a slow hand. A miter box saw with a fine-tooth blade will cut a true 90-degree cut better than any bandsaw.

标识组装完成后,未上漆的部分需要暂时放置,先对标识顶部进行标记,只有足够小的标识顶部才能使用3/16“厚的柱帽。标记完成后,在金属带锯上进行整齐地修剪,当然,也可以使用斜切的盒子锯来切割。

The post caps would be basically glued in place with a small amount of silicone after the sign was installed. The caps were shop-made from scrap pieces of 3/16” thick aluminum bolted together with small countersunk flathead stainless steel machine screws.

标识安装完成后,柱帽会少量的粘贴到硅胶上,柱帽是由3/16“厚的铝制小件制成,由小不锈钢机械螺丝固定在一起。

Before sending the posts and caps to the powder coating shop, the slots in the posts were sanded and filed smooth inside and out so the sign mounting bolts, with their nuts and washers in place, would slide through them easily. The posts were powder coated a Tiger-Drylac “Steel Rack White,” which matched the pre-finished sign faces almost perfectly.

粉末涂层Tiger-Drylac是制作完美标识表面的作用物之一,在将喷头和柱帽送到粉末涂料车间之前,柱帽上的槽会被磨损,从而影响内部和外部的平整度,所以在安装标识时,要注意螺栓的垫圈,它们很容易滑掉。

The assembly in the field literally takes minutes, and no post mounting hardware is visible. Over the protruding studs at each end of the sign, a locknut -- with a flat washer -- is treaded into place. The top nut can be tightened after the fact, but the bottom nut has to be adjusted fairly snug to begin with since it cannot be reached after the sign slides in place on the posts. Soapy water is used as a lubricant to ease the job of sliding the posts onto the ends of the sign, and once the sign is in place on the pots, both top locknuts are tightened securely to permanently attach the posts.

该组装实际上只需要几分钟,并且没有后置的硬件可见。在标识的每一端突出的螺柱上,都有一个带有平垫圈的锁紧螺母,顶部的螺母可以拧紧,但底部的螺母必须紧密地调节好。 使用肥皂水作为润滑剂,以便将柱子能滑动到标识的端部,当标识在罐上就位时,两个顶部的锁紧螺母就能永久地附着柱子了。

This type of no weld sign construction is a quick build project, but it produces a sign that has a clean appearance, is extremely strong and will last for many years. For the client, or the sign maker, what’s not to like about that?

这种没有焊接标识的施工是一个快速的可建设项目,它能产生了一个干净外观的标识,不仅非常坚固,还能持续多年。对于客户来说,他们非常喜欢。