Engravers can help improve a sign shop’s productivity, efficiency and profit margins. They handle work that would otherwise need to be outsourced, for example, and they enable new revenue streams by allowing shops to offer new products to their existing customers. With the enhanced graphic capabilities of three-dimensional (3-D) design software, engravers not only expand upon a shop’s past capabilities, but also enhance its workflow and allow it to respond to last-minute opportunities with better control of finished product quality and delivery.

无可置疑的是,一个功能强大的雕刻机可以有效地提升标识制作的生产力、效率以及利润率,例如,一些标识制作商可能会将项目外包出去,并通过向现有客户提供新产品来实现收入来源。现在,凭借三维(3-D)设计这个新的功能,雕刻机不仅扩展了过去的功能,而且还强化了工作流程,能更好地控制成品的质量,按时交货。

One of the first challenges, however, is to choose between a laser or rotary engraving machine. This will depend on which technology best meets a specific sign shop’s needs, so it is important to explore the differences between them.

然而,在制作标识时选择激光雕刻机还是旋转雕刻机,取决于标识商店和客户的特殊需求,因此,分析好它们之间的区别非常关键。

Laser

激光雕刻机

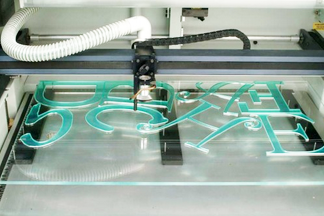

Laser engraving is the preferred process for cutting acrylic for dimensional letters, signs and architectural elements with a flame-polished edge. Its ability to control fine-detail product quality makes it well-suited for cutting tactile lettering for accessibility signage and inlays, without the need to clean up chips after processing.

激光雕刻机用于切割字母尺寸的大小,同时也是带有火焰抛光边缘的建筑标识的首选设备。它具有强大的控制产品细节和质量的能力,其最大的优点是,在应用后无需清理芯片,非常适合切割盲文标识。

Laser engravers excel at productivity, achieving processing speeds up to 4 m (157 in.) per second. They are well-suited for producing large quantities of small items—such as name badges—at the same time and enable fast collection of the cut pieces.

此外,激光雕刻机在生产效率方面也表现得非常优异,它能实现每秒高达4米(157英寸)的加工速度,能快速地整合切片,一般适合于生产大批量的小物品,例如徽章等。

In addition to acrylic, wood and other rigid sign materials, they offer the versatility of cutting fabrics and papers. Some sign materials, such as Lexan polycarbonate, do not lend themselves to laser engraving and will end up with tanned or browned edges. Laminated plastics can show a ‘smoke trail.’ While the level of heat relates directly to the creation of burn marks, ultimately the material itself determines the finish.

除了能较好地处理亚克力、木材和其他刚性材料之外,它还能发挥多功能性来切割织物和纸张等材料。但是,还是有一些材料不适用于被激光雕刻机操作,例如Lexan聚碳酸酯,如果被激光雕刻机处理,会容易变成黑褐色。另外,使用激光雕刻机在层压塑料上会产生多样化的痕迹,痕迹的产生不仅跟热量设置的高低有直接关系,起决定性因素的还是本身的材料。

Larger laser machines can accommodate full-size sheets of engravable materials, with pass-through options that allow for the processing of oversized sheets. One of the issues in this regard is safety. Class 1 offers the safest configuration, whereby the laser is contained within a protective cabinet and the operator cannot be exposed directly to it. This has proven popular with small to midsized sign shops.

大型激光雕刻机非常受中小型标识商店的欢迎,它可以容纳尺寸较大的可雕刻材料,具有处理超大尺寸片材的选项,并且拥有1级安全配置,使激光被包含在保护柜内,操作人员不能直接将它暴露。

With Class 4, on the other hand, the safety precautions are removed by opening the engraving machine’s panels to accommodate oversized materials. The machine can still be safe to use, as long as the operator has received additional training. For this reason, it is common to set up security codes, so only the more seasoned operators can access a Class 4 configuration when needed.

另一方面,在处理超大尺寸的材料时,通过打开雕刻机的面板,可以消除安全防范措施。如果操作人员接受了额外的培训,就可以安全使用机器。因此,在配置上通常会设置安全代码,只有经验丰富的操作人员才能在需要时访问Class 4配置。

The accompanying software can help increase efficiency through ‘nesting.’ This is the process of maximizing the use of the material for the least amount of waste. The optimization of the toolpath is automated and the production time is minimized, too. Nesting can also be used when registering and laser-cutting printed media.

激光雕刻机的随附软件可以最大化提高生产效率和处理材料,刀具路径也能自动优化,最小化地缩短生产时间。

Lasers also enhance graphic capabilities, as they can process high-resolution raster images, photos and special elements like Quick Response (QR) codes, unique device identifiers (UDIs) and bar codes. They can also be deployed for intricate specialty design projects, enabling greater creativity and commanding a premium price. And compared to rotary engravers, they require fewer consumables.

激光雕刻机还具有增强图形效果的功能,能雕刻出快速响应代码,以及独特的设备条形码。它可以处理高分率光栅图像、照片和特殊元素,也可以部署在复杂的设计项目中,实现更完美的创造力,产生更高的价值。此外,与旋转雕刻机相比,它消耗的能源也非常少。

Rotary

旋转雕刻机

Rotary engraving machines have also significantly increased productivity for the sign industry. A single router can automate the entire process of producing braille signs, for example, by routing the sign’s pictogram and text, drilling raster braille pockets and, finally, inserting the rasters into the sign.

同样,旋转雕刻机也能提高标识制作的生产力。单个旋转雕刻机能自动化生产盲文标识的整个过程,例如,通过标识的象形图和文本,雕刻光栅盲文,最后将光栅插入标识中。

Routers are well-suited for engraving metal, polyvinyl chloride (PVC), high-density urethane (HDU), medium-density fibreboard (MDF) and wood. Indeed, they are the best choice for processing the widest range of substrates. And with the use of a long plate, they can enhance workflow further by handling oversized materials.

旋转雕刻机非常适合雕刻金属、聚氯乙烯(PVC)、高密度聚氨酯(HDU)、中密度纤维板(MDF)和木材等一系列材料。实际上,它是处理广泛基板的最佳选择。通过使用长板,它可以较好地处理超大尺寸的材料,来进一步提高工作效率。

Besides engraving, of course, routers are commonly used to cut already-printed substrates. Sign shops have also found new revenue streams by using routers for personalization, promotional and other specialty engraving applications. They can engrave on uneven surfaces, ‘deep engrave’ metal for industrial plates and part marking or even engrave elegant and ornate jewellery and awards with faceted toolmarks.

除了使用雕刻机在材料上进行个性化设计,和专业雕刻以外,标识商店还发现了新的收入来源,利用雕刻机,还可以在不平坦的表面上进行雕刻,例如,在工业板材和零件标记、华丽的珠宝或是刻面上进行雕刻。

Routing is the most efficient engraving process for large, filled text. There are ‘2.5-D’ and 3-D options for sign elements, moulds and dies. Another advantage is no exhausting or filtration is required.

旋转雕刻机是大型填充文本最有效的设备,元件不仅具有“2.5-D”和3-D选项,操作时还不需要过滤。

Working together

共同作用

In the final analysis, while laser and rotary engravers offer different strengths and capabilities, they also complement one another and can prove useful together in a high-volume production environment. They have both proven themselves beneficial, for example, in the design and production of creative point-of-purchase (POP) displays.

归根结底,激光雕刻机和旋转雕刻机各具有不同的优势和功能,但它们也可以相互补足,并在生产环境中一同作用。例如,在POP显示器的设计和生产中,它们一同作用能实现更好的效果。

Similarly, productivity can be further increased with the addition of bevelling machines, metal or plastic shearing tables, cutter-grinders, saws, corner shapers and engraving enamel. All of these tools and consumables have helped modernize production processes in the sign industry and optimized profits, while still fostering artistic creativity.

同样,通过增添斜切机、金属或塑料剪切台、切割机、成型器和雕刻搪瓷,也可以进一步提高生产率。尽管这些工具已经能优化标识的生产过程,帮助企业实现最大化利润,但科技没有终点限制,仍需要继续创新。