Most sign companies order their channel letters from wholesalers due to the cost and machinery involved. If you’ve ever wondered what goes on behind the scenes, here’s a look.

考虑到成本和设备的问题,大多数标识公司都会从批发商那里订购发光字材料。如果你想知道幕后发生了什么,请接着往下看。

One ofDirect Sign Wholesale’sclients, Kerley Signs (Landover, MD) , recently ordered an interesting channel letter sign: Café Roma. This sign included a number of custom elements (including a logo box, vinyl overlays and a custom-paint color) which made for a detailed production process.

标识批发商的其中一位客户,克利标识(兰德,马里兰州),最近被要求为罗马咖啡厅制作一个有趣的发光字标识。这个标识包括许多自定义元素(包括标识灯箱、乙烯基覆盖层和定制颜色),这些自定义元素都是为了后期详细的生产过程而准备的。

“This project was a direct result of relationship building,” said Patricia Kerley Rust, head of sales/business development for Kerley Signs. “My father, Tom, has known Lenny Romano of Nardi Construction [Kerley’s client] for 20 years, and we have worked with them on several signage projects. When their company requested this sign, we relied on our relationship with Direct Sign Wholesale.” And so, our job began.

克利标识的销售/业务发展主管Patricia Kerley Rust说:“这个项目的建立是出于友情的关系。我的父亲汤姆和我的这位客户相识已有20年,我们也曾经和他们一起为建立几个标识牌项目而合作过。当他们公司需要制作这个标识时,我们便向我们的标识批发商寻求帮助。”相关的标识制作工作也由此展开。

ROUTING THE LETTERS

切割发光字的外形

One of the initial channel letter production steps is routing both the acrylic letter faces and metal backs. The letter faces are produced from acrylic and the backs from aluminum. Routing cuts specified shapes from various material sheets using a CNC interface.

制作槽型发光字的第一步是对字体的亚克力材料表面和金属材料背面进行切割。用亚克力材料来制作发光字的表面,用铝材来制作发光字的背面。使用CNC设备可以将各种板材切割成指定形状来为后期的工作提供便利。

This sign’s custom font was an important production consideration. For channel letter signage, specialized fonts can be an issue. Clever as some of these letter designs may be, they’re not always configured with electrical signage construction in mind. Due to the relatively slim design of this sign’s letters, for the face we utilized “sign grade” (a type of impact-modified) acrylic. This material is stronger than standard acrylic and is often used for letters with a relatively thin stroke (or width).

标识的定制字体是一个重要的考虑因素。对于槽型发光字标识来说,专业的字体设计可能就是一个需要好好考虑的问题。一些发光字的字形设计虽然精美,但它们并不适合电子标识设计的结构理念。由于这个发光标识的外壳设计相对较薄,因此我们选择使用一种冲击改性的亚克力材料作为表面。这种材料比常规的亚克力更坚固,通常用于制作相对较薄(或较宽)的发光字。

An entire channel letter set can sometimes be cut from a single material sheet depending on the quantity and size of the sign elements. For this project, the letter faces and logo box were both routed from a single 60 x 120-in. acrylic sheet with a thickness of 3/16 in. We routed the backs from two 48 x 22-in. (0.063-gauge) aluminum sheets.

根据标识的质量和大小,有时候我们可以从单个板材上切割下一套完整的发光字字形。就目前这个项目而言,发光字表面和标识灯箱的切割大小都是60×120英寸。我们选择的亚克力板材厚约3/16英寸,背部的材料我们则是选择两个48×22英寸(0.063规格)的铝板。

A REVEAL-VINYL FACE

一个精致的发光字表面

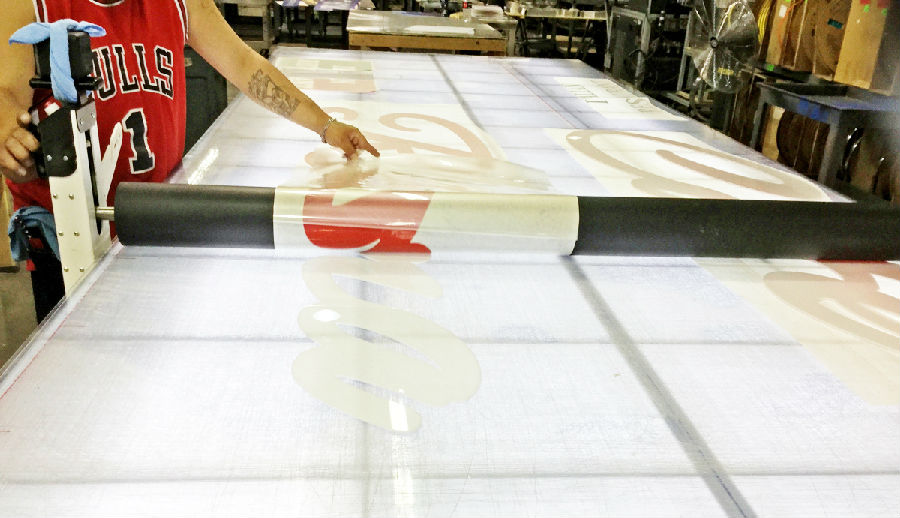

The next step was the cutting and application of the vinyl for both the letter faces and the logo box. This sign’s design included a “reveal” face vinyl configuration for the letter faces, and that composition required that the vinyl be precisely placed.

接下来的步骤就是对乙烯基材料进行切割,并将其应用到发光字表面和标识灯箱上。这个标识的设计要求将一个“暴露”的乙烯基材料精确地安装在发光字表面。

A reveal-vinyl configuration does not cover the entire letter face. Rather, the vinyl is positioned inside the letter stroke using an illuminated CWT work table and an accompanying roller gantry, so an acrylic border around the vinyl is visible. This con-figuration outlines the letter shape for increased sign legibility, particularly at night.

这个暴露的乙烯基材料外壳并不能覆盖住整个发光字的表面。相反,乙烯基材料是被固定在发光字的内部,并使用一个照明的CWT工作台和一个附属的滚筒门架进行固定和发光,所以乙烯基周围的亚克力材料边界是可见的。这种搭配可以使发光字的外形更明显,增加了标识的可视性,特别是在夜间,非常容易被看见。

With the letter-vinyl application complete, we placed the vinyl in the logo box, which included three vinyl elements – the red and green side colors and the words “Italian Restaurant.” For this configuration, the separate vinyl pieces were laid down in stages. The side colors were dropped onto the acrylic sheet first, then “Italian Restaurant,” followed by a quality-control check for positioning.

当发光字表面的乙烯基材料安装好之后,我们将乙烯基材料安置在包含有三种乙烯基元素的标识灯箱里——这个标识灯箱的两边颜色分别是红色和绿色,并且在表面标明着“意大利餐厅”的字样。针对这种外形结构,分开的乙烯基材料被分阶段放置进灯箱中。首先将两边的材料安装在底层的亚克力板上,然后对“意大利餐厅”这几个字进行精确的定位和检查。

RACEWAYPRODUCTION

灯箱字槽的产生

This letter set also specified raceways. A raceway is an optional external mounting structure for a channel letter set (as opposed to flush mounting). Raceways are typically painted a similar color to the building façade to blend in with the mounting location.

这个发光字系列对字槽的设计也有要求。与埋入安装不同,这个字槽管道是在外部安装发光字的一种结构类型。字槽通常被涂上与建筑表面类似的颜色以保持与安装位置毫无痕迹的契合。

The total raceway length specification was 231 in. This overall length was subdivided into three separate sections – one with a length of 93 in. (for the word “Café”), one of 88 in. (for the word “Roma”) and one 50-in. raceway for the logo box. Raceway construction also involves a router. An aluminum sheet isrouted to the correct length, and the mounting and electrical pass-through holes (on the raceway front) are also cut at that time. We then bend the finished sheet into a raceway shape using a CNC Brake.

字槽的总长度约为231英寸,并且分为三个单独的部分。一个长度为93英寸(安装“咖啡”一词),一个长度为88英寸(安装“罗马”一词)和一个长约50英寸标识灯箱的字槽。字槽在安装前同样需要进行切割,将铝板切割至合适的长度,同时切割掉多余的材料和电气通孔。最后,我们使用CNC设备将成品板材折弯成适合字槽的形状。

When clients specify a custom raceway color, using the appropriate type of paint is vital for a long-lasting letter set. The paint must be able to handle prolonged outdoor exposure without fading, chipping or peeling. The raceway color specification was SW 6108 Latte. We used Sherwin-Williams Genesis LV, a low-VOC urethane coating with a chemical/solvent resistant finish, ideal for the conditions this sign would endure.

当客户指定字槽的颜色时,为发光字挑选适当的颜色对于其使用时间的长短是至关重要的。选用的颜料必须能够长时间的暴露户外而不会褪色、碎裂或剥落。字槽的颜色规格是SW 6108拿铁。我们使用了具有化学/耐溶剂表面的低VOC的聚氨酯涂料Sherwin-Williams Genesis LV,这种颜料非常适合标识表面的装涂,并能够帮助标识抵抗天气条件所带来的不确定因素。

Next, a 60W Optodriver power supply was placed in each raceway. The raceway structure also received electrical and grounding wires along with a disconnect switch. (As a side note, one advantage of raceway-mounted channel letters is easy wiring accessibility simply by removing the lid.)

接下来,在每个字槽上放置一个60W的Optodriver电源。字槽还可以通过断路开关将电线和接地线连接起来。(这也是槽型发光字的一个优点,即只需要简单的取下盖子就可以直接接线。)

TRIM CAP AND RETURN BENDING

修剪帽和反复折弯

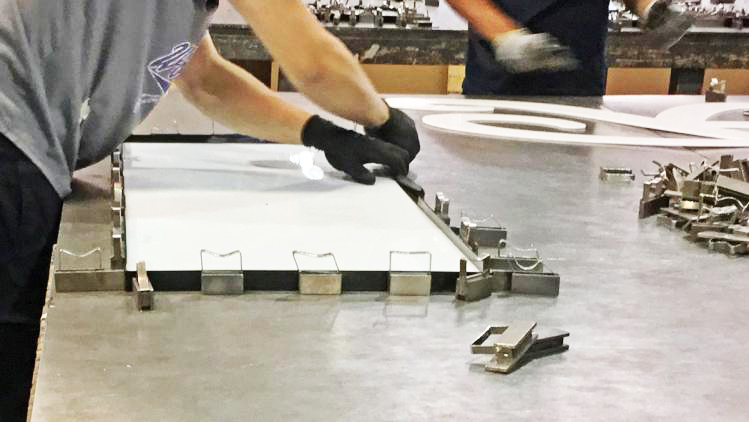

The next step was bending and attaching the channel letter trim caps, the plastic molding that affixes the acrylic faces to the letter returns. This project specified a standard prefinished black trim cap. An SDS trim cap machine notches the caps which are then permanently attached using Weld-On #3 and #16 adhesives.

下一步是进行折弯操作和为发光字添加装饰帽,将成型的亚克力材料和发光字表面黏合在一起。这个项目指定了一个标准的预制黑色装饰帽。使用SDS装饰帽切割机对指定的材料进行切割,然后使用Weld-On#3和#16粘合剂进行永久的黏合固定。