LED illumination has progressed substantially as a sign lighting media, and is now generally regarded as the primary illumination product for channel letter signage. However, LED must be configured and installed properly to generate optimal channel letter illumination. This article details some of the “best practices” associated with the use and placement of LED modules in channel letter signage.

LED作为一种照明,应用在标识中,已经取得了长足的发展,通常被认为是发光字的主要照明源,因此,正确的配置和安装LED变得格外重要。本文将通过实际操作,详细介绍在发光字中,如何正确地使用和放置LED模组。

What is accomplished when these best practices are used? They are:

首先,正确配置和安装LED需要具备以下条件:

· Illumination Brightness – the letter luminosity is clean and vivid

· 照明亮度 - 字母的亮度清晰

· Illumination Evenness – light dispersion is equal across the entire letter face or halo

· 光照均匀 - 整个字母的表面或光晕部分分布均匀

· Lighting Consistency – each sign element (letters and/or logo box) has equivalent brightness

· 照明一致性 - 每个元素(字母和或标识框)具有相同的亮度

· Color Optimization – the LED configuration utilized is appropriate for the face color

· 优化颜色 - 所配置的LED适合标识面部的颜色

· No Module Visibility – LED mounting locations are not visible when viewing the illuminated sign

· 模组的隐藏性 - 查看照明标识时,LED模组安装的不可见性

Proper execution of these practices produces a compelling and vibrant letter sign that will generate referrals for your signage business.

无论如何,只有正确的配置LED,才能制作出一个精美的发光标识,为您的标识业务带来更多口碑。

Module Placement Planning

模组的整体布局与规划

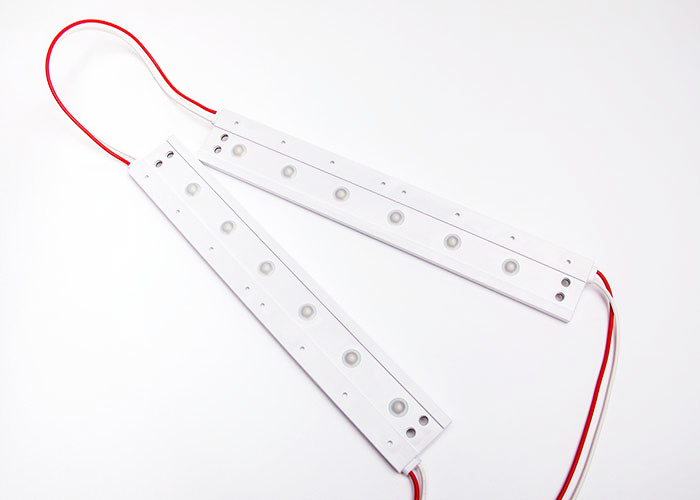

First, the initial best practice is to review the LED module manufacturer specifications prior to planning the module placement. Many LED producers provide a “single stroke” recommendation for their modules (in this context, a “stroke” is the side to side width of the letter return.)

首先,在规划模组的布局之前,需要先审查LED模组的规格,许多LED制造商为他们的模组提供了有关描边厚度的标注。

For example, if your channel letter has an 8” stroke width (which is large) and the manufacturer recommends a maximum 6” stroke for a single strip of LED modules, then two strips of LED would be necessary for bright letter illumination.

例如,如果字母有8行程的宽度,制造商会建议对于单个LED模组最多设置6行程的宽度,对于字母的照明,只需要两条LED灯条即可。

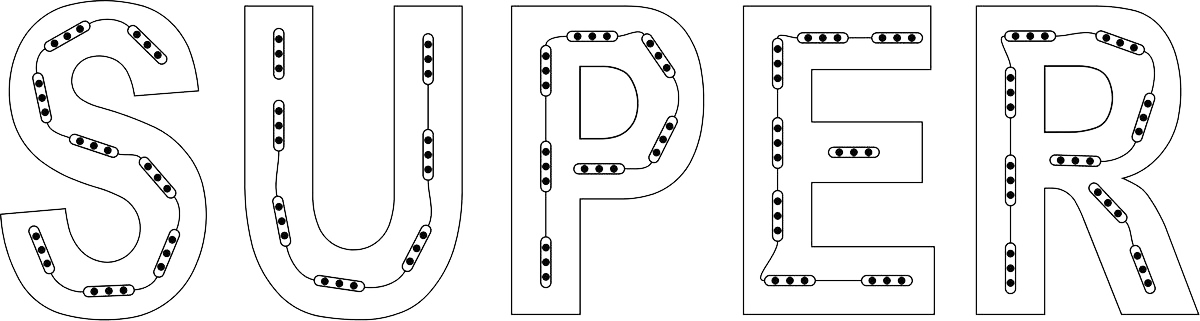

LED Module Placement Diagram

LED模组的放置

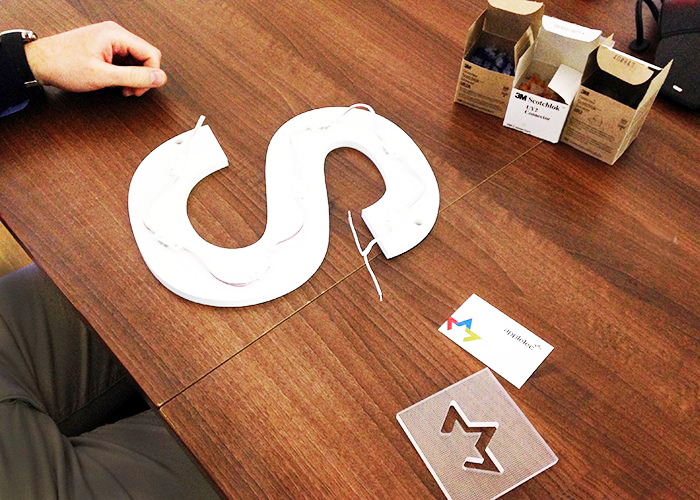

One excellent practice is to produce and illuminate a test letter when populating a new brand of LED. The completed initial letter is then evaluated for luminance, evenness and lighting consistency prior to populating the remainder of the sign.

在填充一个新的LED模组时,先进行测试,然后在填充字母的其余部分之前,对完成的首个字母的亮度、均匀度和光照的一致性进行整体评估。

Finally, a quality LED layout plan will also include a review of the letter structure and design prior to deciding on the quantity and position of the modules. If the letters include serifs or other decorative elements, the LED placement must be adjusted to account for any potential lighting issues resulting from the channel width variance.

此外,LED的布局还包括在决定模组的数量和位置之前,对字母的结构和设计进行审查。如果字母的衬线或其他装饰元素没有协调好,应调整LED的位置,描边宽度的变化会影响潜在的照明效果。

How to Generate Even Face Illumination

如何生成连续的面部照明

Another illumination objective is even illumination across the entire letter face (i.e., the entire face acrylic or halo area is equally bright.) For front-lit letters, two lighting conditions to avoid are “tiger striping” and hot spots.

正确配置LED需要注意的另一个点是,在整个字母上生成连续的面部照明(即整个标识面部的丙烯酸或晕圈区域都有同样的亮度)。对于字母的正面,需要避免虎纹和斑点的出现。

Both of these issues refer to one area of the face being significantly brighter than an adjacent area. A “tiger stripe” refers to an entire strip of the letter face that is visibly brighter than a bordering strip.

出现虎纹和斑点这两个问题都会导致一个区域比邻近区域的光源明显更亮。虎纹指整个字母表面呈现的条纹。

Tiger striping is typically observed when the LED modules have a viewing angle that is too narrow. If too much of the “sweet spot” (brightest part) of the illumination is focused on a narrow vertical strip, then it may take on a brighter appearance than an adjacent strip of the face. Using an LED with a wider viewing angle will typically solve this issue.

当LED模组的视角过窄时,通常就会观察到虎纹。如果标识面最亮的部份过多地聚焦在狭窄的垂直边上,也会产生比面部相邻边更明亮的外观,因此,需要使用具有更宽视角的LED模组来避免此问题的产生。

By comparison, a “hot spot” can mean one of two different conditions. It may refer to a smaller face area that is significantly brighter than an adjacent area, or it may mean that the LED modules are actually visible through the face acrylic.

相比之下,产生斑点意味着有两种不同的问题所在,第一种情况是,可能指该区域比邻近区域或较小面部区域的光源更亮,第二种情况可能意味着LED模组通过面部的丙烯酸就可看见。

Smaller hot spots (one area brighter than the next) can have several causes. One potential cause is the sign did not receive a power supply that is capable of delivering enough power to properly illuminate the entire module population. Modules that are further down the LED series may not be receiving sufficient current. This scenario is more likely with constant voltage LED (instead of constant current.) A power supply with sufficient current may address this problem.

过热部位的光比其他区域的光更亮可能有几个原因所致。其中,一个潜在的原因是,该标识没有获得足够的电流,来供整个模组的电源。另一个原因是,位于LED模组下方可能没有接收到足够的电流,这种情况更可能与恒压发光二极管有关,而不是恒定电流。

The visible module hot spot condition is typically observed with specific shades of blue, green and yellow letter face acrylic. Certain shades within that color set have a high degree of translucency, and an illuminated LED module may actually show through the face.

另外,带有蓝色、绿色和黄色亚克力材料的字母通常容易显示出模组的轮廓。由于这些颜色设置中的某些阴影具有高度的半透明性,LED模组实际上可以通过面部的材料就能显示出来。

Low acrylic density is another potential cause of LED module visibility. Face acrylic is available in both 1/8” and 3/16” thickness. Lower density face acrylic (1/8” thickness) is obviously more susceptible to LED module visibility.

低密度的丙烯酸是LED模组可见的另一个潜在原因。较低密度的丙烯酸的厚度为1/8“,这种厚度非常容易受到LED模组的影响。

One approach to addressing visible modules is placing diffuser film on the letter face interior. This material helps to control the light distribution within the letter and produce an even illumination appearance.

解决可见模块的一种方法是,将漫射膜放在字母的内部,这种材料有助于控制发光字内部的光线分布,并产生均匀的照明外观。

Colored LED Illumination

如何配置彩色LED照明

Another LED product can increase the intensity and effectiveness of a channel letter set – colored illumination. Some LED producers offer modules which emit colored lighting instead of standard white, and professional usage of that product can also be an illumination best practice. However, colored LED modules often have a higher cost than standard white.

LED通常还能增加发光标识的强度和耐用性。一些LED制造商所提供的彩色照明并不是标准的白色模组,它们使用起来产生的效果并不输给白色LED,但是,彩色LED模组通常比标准白色模组的成本高。

However, that scenario assumes the entire sign has the same red acrylic face layout. The situation changes if one part of the sign has standard acrylic while another part has a vinyl face pattern (such as a logo box mounted adjacent to a letter set.)

但是,在另外一种情况下,当整个标识具有相同的红色亚克力面孔布局时,如果标识的一部分具有丙烯酸,而另一部分具有乙烯基(例如,在字母边上安装标识盒),情况则会发生变化。

In that example, using red LED throughout the entire sign is probably not a good idea – it will benefit the letter faces but could cause a problem within the logo box. White LED may produce a superior logo box appearance. So, for optimum illumination this sign would include both white and red LED modules.

所以说,并不一定是整个标识使用红色LED就能发挥好的效果,这仅仅只是有利于字母的表面,但对于标识框的内部,则会出现其他问题。在标示框的内部,还是需要用到白色LED,才会产生出众的外观。所以,为了达到最佳的照明效果,有时标识需要同时用到白色和红色两色LED模组。

Also, the practice of matching the LED color to the face color does not necessarily carry over to other configurations. For example, some LED producers offer modules with orange illumination. However, orange acrylic does not typically require orange LED for effective lighting. White LED usually works fine for orange face acrylic illumination. In this case, the higher cost of colored LED is typically not warranted.

此外,将使用LED的颜色与标识面部的颜色相匹配不一定牵扯其他的配置。例如,一些LED生产商能提供橙色照明模块,而橙色丙烯酸酯制作的发光标识通常不需要橙色LED来作为照明,它们需要白色LED,白色LED才适用于橙色亚克力制成的发光标识。

Blue LED is one more example. This color can also present challenges when improperly used. Dark blue acrylic already has an inherent issue of absorbing much of the letter illumination rather than emitting it, and can result in a dark letter appearance. Combining blue LED with dark blue acrylic may compound this problem.

另外一个要说的例子是蓝色LED。深蓝色的压克力容易吸收字母的光,从而导致字母的外观变得黑暗,这是蓝色LED与深蓝色丙烯酸结合起来所产生的问题。所以说,如果这种颜色的LED使用不当,会产生很大的影响。

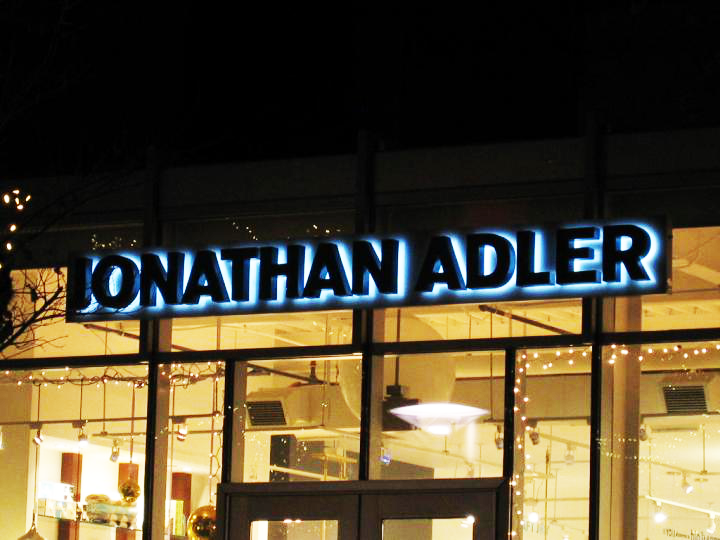

However, blue LEDs can present a striking appearance for halo lighting of reverse-lit channel letters. So a blue LED certainly has legitimate applications but it must be used with caution for front-lit channel letters.

此外,蓝色LED对于发光字的光晕效果能呈现惊人的表现。所以蓝色LED必须针对性的进行应用。

Interior Can Treatments

内部结构的处理

The composition of the letter return itself also contributes to the LED illumination performance. Reflective paint for the return interior (inside of can) is available for the purpose of both increasing and improving letter illumination.

除了以上所提到的,字母本身的组合也有助于LED照明的性能提升。反光涂料的内部可用于改善文字照明的强度。

Traditional channel letters have a standard 5” return depth. That means the illumination must travel a full five inches from the module prior to reaching the letter face. That seemingly small distance may actually have serious implications.

例如,传统发光字有一个标准为5“的深度,这意味着LED模组到字母表面必须满足五英寸的距离,这个距离看似很小,实际可能产生重要的影响。

First, the LED light actually “bounces” from side to side of the letter interior prior to reaching the face. If the letter can interior is untreated, that bounce can mean the light luminosity received by the acrylic actually decreases prior to reaching the face.

另外一个方面值得注意的是,如果发光字的内部未经处理过,丙烯酸接收光的亮度会减少。

Ricochet lighting occurs because of the LED module viewing angle, or “fan of light” produced by each module. Some of that light fan will bounce – possibly repeatedly – off the return wall prior to reaching the face. That internal ricochet can produce a compromised level of face lighting consistency and brightness if the interior of the return is untreated (standard aluminum.)

LED模组的可视角度,以及每个模组产生的光扇,都会影响照明的稳定性。如果内部未经处理,那么内部的弹性可能会导致面部照明的一致性和亮度降低。

A painted letter interior will help to increase the lighting ricochet and take full advantage of the LED capabilities. This configuration will typically have a superior illuminated appearance compared to a set with an unpainted interior and can be a best practice when used properly.

一个彩绘字母的内部如果能充分利用LED,将有助于增加照明的稳定性。与没有上漆的内饰相比,它具有优越的照明外观,但有正确使用了LED,才能产生最佳效果。

White is the interior color of choice because of the high light reflectance value (LRV). Typically white has an LRV of over 80 percent, and this means a bright reflection of the interior light and subsequent brighter face illumination.

由于高反光值(LRV)的限制,白色是标识内部颜色的合适选择。通常情况下,白色LRV超过80%,内部光线的反射和面部照明都会非常明亮。

In addition, demand for 3” channel letter returns (rather than 5” depth) has been increasing. This shallower distance reduces the internal light bounce and focuses more of the “prime” LED illumination onto the acrylic face.

此外,发光字折弯深度的需求正在增加,也因此从5”变成了3”,这个较浅的距离减少了内部光线的反射,将更多LED照明源聚焦到了丙烯酸的面板上。

Conclusion

总结

LED modules have evolved into the primary source of illumination for channel letter signage. However, they must be used properly for clean, even and bright letter signage illumination. Following these practices increases the chances that your client will receive a professional and well-illuminated channel letter set.

LED模组已经发展成为发光字的主要照明源,它们必须正确使用,才能发挥干净明亮的照明效果,增加了您的客户对成品的满意程度。