Channel letters can be seen in millions of highly visible places around the country—on everything from plazas to hotels, restaurants, malls and corporate signage. They can be illuminated brightly during evenings, and don colorful sign faces for day viewing. And though some of the actual channel letter bending work can be done by hand, much of it today is performed by machine.

你可以在任何一个高度可见的建筑物上发现发光字标识的存在——比如随处可见的广场、酒店、购物中心和企业高楼上的标识。这些标识在夜晚点亮时可以为人们提供指引,在白天则可以凭借其丰富的外壳色彩来装点店面。尽管一些槽型发光字可以通过手工完成,但如今越来越多的工作都开始交由机器来完成了。

“Ninety-five percent of the letters can be formed and bent much more accurately and faster using an automated channel letter machine,” says Carl Ondracek, president, Computerized Cutters, Plano, Texas, manufacturer of the Accu-Bend channel letter bending machine.

德克萨斯州普莱诺市的Accu-Bend发光字折弯机制造商Computerized Cutters公司总裁Carl Ondracek说:“95%的发光字都可以通过使用全自动标识折弯机进行快速地折弯和成型。”

Like many facets of the sign industry, channel letter production improved throughout the years. Sign makers now have a way to finish the job accurately and with the highest level of quality, especially when fabricating multiple letters for several projects.

和标识行业许多其他方面一样,发光字产品在近几年来一直在不断地改进。标识制造商现在可以顺利地完成工作并且使产品达到非常优越的质量水平,特别是在为好几个项目制作多样化的发光字时。

Precision Machinery

先进的设备

With the advanced equipment that is available for all channel letter bending needs, users need to understand what to use and how to use it. Machine manufacturers can provide a breadth of knowledge in this area, and are happy to assist sign makers with equipment decisions. In some instances, becoming a trusted partner of sign shops.

目前借助先进的生产设备几乎可以满足任何槽型发光字折弯的需求,因此用户需要了解他们想要生产什么产品以及如何使用它。设备制造商可以在这方面为用户提供相关的知识科普,并积极协助标识制作者做出设备的购买决定。在某些情况下,他们可以成为标识商店值得信赖的合作伙伴。

“In my opinion, it is never appropriate to not use automated equipment,” states Trea Sciortino, owner, Letter Fab LLC, a wholesale channel letter provider in Crested Butte, Colorado. “The equipment available is CNC router tables, CNC letter bending machines and clinch machines, to name the most important. There are many custom-made tools in our shop as well as a skilled group of tradesmen to make a superior product.”

位于科罗拉多州克雷斯特德比特的发光字批发供应商Letter Fab LLC的老板Trea Sciortino说:“在我看来,自动化设备应该得到推广和普及。可以使用的设备包括数控平板切割机、数控折弯机和铆接机,这些都是很常用的设备。我们店里拥有许多定制工具,还培养了由一批熟练工匠组成的队伍来生产优质的产品。”

Before automated letter bending product lines existed, sign makers were content with performing each job by hand. But when the need for mass production and replication increased, today’s equipment filled a gaping need.

在出现自动化标识折弯生产线之前,标识制造商通常是自己亲自完成每项工作。但是当大规模的批量生产需求增加时,如今的自动化设备就填补了这些需求的空白。

“Now, we use a machine to do all that work,” says Kevin Kane, owner, CLN of South Florida, a manufacturer of a variety of automated channel letter equipment. “A channel letter machine and router table and a Quick Trim machine; this has let sign makers make more money than ever, producing letters faster than ever. Even the smallest shop can take advantage of this equipment, getting off the metal bench and back to a new customer. What’s your time worth?”

南佛罗里达州的CLN公司(生产各种自动化标识折弯机的制造商)的所有者凯文·凯恩说:“如今,所有的工作我们都可以使用机器来完成。一台发光字折弯机、一台平板切割机和一台快速切割机共同工作就可以使得标识制造商赚取比以往任何时候都多的利润,生产发光字的效率也比以前更高效。即使是最小的商店也可以利用这些设备,这样就可以解放劳动力并更多地为客户服务。时间对于每个人来说都是非常宝贵的。”

Channel letter bending machines bring necessary advantages to the sign maker including greater speed, accuracy and overall productivity.

标识折弯机为标识制造商带来了更大的优势,包括更快的速度、更高的准确性和生产力。

“Most letters that take an average of 45 minutes to layout, notch, flange and bent to shape can be done on the Accu-Bend machine in about three to four minutes,” says Ondracek, pointing to the speed of this equipment.

Ondracek说:“在大部分情况下,手工制作一个发光字,从设计、切割、折弯直至成为一个形状完整的发光字标识大约需要45分钟,而这一切仅仅需要3~4分钟就可以通过Accu-Bend公司的设备来完成。”

Quickness in channel letter bending is something that is vital to sign makers. In the event that they are fabricating letters on tight deadlines, they need to know that they will get the job done correctly and efficiently.

对于标识制作者来说制作折弯标识时的速度至关重要。如果在截止日将近之前他们还未完成标识的制作,那么他们就需要知道如何才能正确有效地完成工作。

“The fastest equipment I’ve seen is our CLN Auto Bender,” says Kane. “It has roll forming technology; this allows the radiuses to be formed with rollers that produces a smooth and fast radius.”

凯恩说:“由我们公司生产的CLN Auto Bender,是我见过的效率最高的设备。它具有滚压成形技术,在进行滚压的同时可以快速地形成一个平滑的半径。”

With the benefit of the machine forming the arc radius and following specific measurements, a significant amount of time is saved in the sign shop. Additionally, compatible software programs greatly simplify the processes.

利用机器形成圆弧半径以及获得的具体测量结果,标识商店可以节省大量的时间。另外,兼容的软件程序大大简化了制作过程。

“Just import a .DXF file, select the letter, and press go,” Kane sums up.

凯恩表示:“你只需导入一个.DXF格式的文件,选择一个字体,然后按下去就可以了。”

Sciortino runs through the process of how software feeds channel letter bending machines the job details, explaining the “abracadabra” part of the method.

Sciortino观看了软件如何为标识发光字折弯机提供工作细节的过程,解释了该方法令人困惑的部分。

“We have to have a vector-format file to produce what is called a .DXF file, which the CNC equipment can then read lines and arcs. there are many sensors, motherboards, and highly engineered components to drive these machines.”

“我们必须有一个矢量格式文件来生成.DXF格式的文件,使数控设备可以读取标识的线条数据和外观弧线数据。这些设备由大量传感器、主板和高级设计软件共同工作来达到驱动的目的。”

Ondracek agrees, “Most files are .DXF files sent from the same sign software that is creating and sending the files to the router table for cutting the aluminum backs and plastic faces.”

Ondracek对此表示赞同:“大多数.DXF格式的文件都由同一个标识软件发送而来,这些软件在创建好相应的格式文件之后,将文件发送到平板切割机的数据库中,用以切割成型标识背面所需的铝制材料和正面所需的塑料材料。”

Again, this helps sign makers save time and allows them to handle more profitable high-volume projects—which should ultimately be the goal.

通过这种运作方式,设备的使用可以帮助标识制造商节省大量的时间,而标识制造商就可以利用好这部分时间来处理更多可盈利的工作——这应该成为标识制造商们最终的目标。

“Low volume channel letter manufacturing is not acceptable for wholesale manufacturing,” explains Sciortino. “The only way to provide a living for the staff—and pay the government—is through high volume. A speedy turnaround would be three days. Some larger channel letter jobs can take up to three weeks.”

Sciortino解释说:“对于批发制造业而言,低批量的标识发光字订单是远远不够的,要想为员工提供更优质的生活和向政府交纳相应的税款,唯一的办法就是大批量地进行标识生产。流程快速的工程大概需要三天,而一些大型的标识发光字制作项目也可能需要长达三周的时间。”

In order to get the most out of the machine, and complete a project in a timely manner, it is important to understand all of the parts of the channel letter.

为了充分利用机器,并及时完成工作,了解发光字的所有构成部分非常重要。

Letter Characteristics

标识发光字的特征

“A plastic face channel letter has three components,” explains Kane. “The back, which is usually aluminum, but sometimes it could be made out of Dibond material; the return, which is aluminum and is cut off a coil roll; and the face, which is a translucent material, usually a plastic like acrylic, and lets the light shine through.”

凯恩解释说:“一个表面外壳由塑料材料制成的标识发光字由三个部分组成。这种标识的背部材料通常是铝制的,但有时也可以使用铝塑板制作而成;标识内部的反射通道由铝材制成,并且被切割成一个卷曲的断面;而标识的表面则多使用半透明的塑料材料制成,比如亚克力材料,这种材料可以非常轻易地让光线通过。”

So, let’s take a look at each one of these elements individually to break down what sign makers should consider while handling a channel letter project.

因此,为了让标识制造商在处理标识项目时考虑得更全面,下面让我们分别来了解这些每一个元素的特点。

The Return

反射通道

Depth is a big consideration with channel letters. It makes up the sides of the letter and determines its depth.

发光字标识的深度通常是一个重要的考虑因素,它将影响发光字两侧的材料选择和制作深度。

“Standard channel letters are typically five inches deep because of the history of neon illumination in the letter,” explains Sciortino, but with the popularization of LEDs, these measurements can be much lower. “Even though we still make many five-inch deep channel letters with LEDs, we also have manufactured many four-inch and even three-and-a-half-inch deep letters which, in turn, puts the face closer to LED module making for a better-illuminated letter.”

Sciortino解释说:“从标识分类中的霓虹灯照明历史出发,发光字的标准深度通常为5英寸,但随着LED的普及,这些测量值可能会低得多。尽管我们仍然使用LED制作了许多5英寸深的发光字标识,但我们也制造了许多4英寸甚至3.5英寸深的发光字标识,这反过来又使得发光字面板更接近LED模组,由此发光字也获得了更好的照明效果。”

Kane confirms that the depth of the return is dictated by the illumination source, and that “Neon for example, throws off more illumination so the return needs to be deeper so that the light source is further away from the plastic letter face. This ensures that the plastic has an even distribution of light, and no hot spots.”

凯恩证实,标识内部的光线反射深度是由照明源决定的。“例如,霓虹灯照明亮度更强,因此光源的反射通道也需要更深一些,以便光源远离标识的塑料表面。这确保了光源照射在塑料外壳上的光线分布均匀,不会产生光斑。”

And when moving to an LED lighting configuration, the depth of the return can be much less. “The LEDs are attached at the rear, on the letter back, and the light is further away from the plastic face,” says Kane. “With neon we have to mount the glass on tube supports, which pushes the illumination closer to the face requiring a deeper return.”

当我们开始讨论LED照明的结构时,光源内部的反射深度就会浅得多。凯恩说:“LED模组通常安装在标识和发光字的背面,因此光线离塑料表面的距离较远。而针对霓虹灯而言,我们必须将玻璃管安装在支架上,照明光源也会更接近标识表面,因此发光字就需要更深的反射深度。”

Quality is another consideration with the return. As Sciortino mentions, “Not all channel letters are made the same,” which can impact the actual bending process.

质量问题是计算反射深度的另外一个考虑因素。正如Sciortino所提到的:“并非所有的发光字都是一模一样的,其反射深度会受到标识实际折弯程度的影响。”

“Only companies with accurate CNC equipment can play in the same league for consistent quality and speed of getting sign projects to the consumers in a timely manner,” Sciortino says.

Sciortino说:“一个公司只有拥有精密的数控设备才能在同行中脱颖而出,并且应该及时向消费者提供保质保量的标识产品。”

In general, the return depth “ranges from two inches to six inches for 95 percent of the channel letters,” Ondracek says. “Material thickness ranges from 0.032 to 0.063 inches. Most machines cannot handle the 0.063-inch, especially for notching and flanging; this would be important in selecting a machine.”

Ondracek说:“一般情况下,95%的发光字的反射深度范围在2~6英寸之间,材料厚度在0.032~0.063英寸之间,由于大多数设备不能处理0.063英寸厚度的材料,尤其是标识的折边和切角,因此选择合适的设备就显得尤为重要了。”

Flanging/Notching

发光字的折边和切角

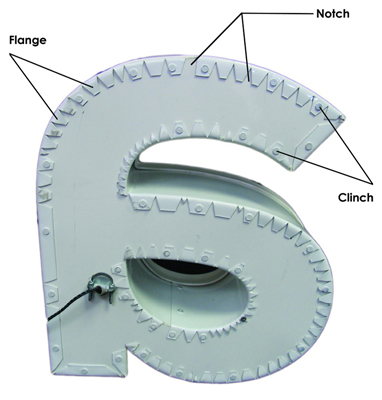

Speaking of notching and flanging, this is a practice that is necessary in channel letter production. In order to secure the letter back to the return, the bottom of the return must be notched and flanged to match the curve of the letter shape.

折边和切角是制作发光字时的必要程序。为了使发光字内部的反射通道能够正常运作,发光字的底部必须有切角和折边来使材料更贴合发光字外观的曲线。

“In the past, this was done with tapes, strings and metal shears until the ‘hand notcher’ tool was invented for the channel letter craftsman making this product completely by hand,” explains Sciortino. “Nowadays, to be competitive, we must use automated equipment.”

Sciortino解释说:“在过去,这一步骤是由胶带、绳子和金属架来完成制作的,直到帮助这些手工制作标识发光字的工匠们的‘手工刻槽工具’被发明出来。在现在这个社会,想要具备竞争力,我们就必须使用自动化设备。”

Sign makers can rely heavily on this equipment to perform the necessary functions that ultimately lead to shaping a channel letter.

标识制造商可以充分信赖设备所具有的相关功能,并设备的帮助下生产出发光字产品。

“Channel letter machines drive aluminum coil through the mechanisms in the machine,” Sciortino continues, “which measure, notch, flange and bend the shape of the letter. Some machines are better than others for this process.”

Sciortino继续说:“标识折弯机通过设备内部的运作将铝材卷曲成型,再对发光字进行测量、切角、折边和折弯等处理,制作出成品的发光字。有一些设备比其他设备能够更好地进行此项操作的处理。”

Overall, the machine works to “put notches in the material where needed, and the machines will bend the bottom 0.5 inch at a 90 degree angle to form a flange for attaching to the back of the letter return,” says Ondracek.

Ondracek说:“总之,该设备的工作原理是将切角连接在材料需要的地方,随后设备可以将切角材料底部0.5英寸的部分以90度的角度进行折弯以形成折边来贴合发光字的背面材料。”

The Letter Back

发光字的背面

When the flange and return have been completed, it’s time to assemble the rest of the letter.

当发光字的折边和反射通道都处理好之后,我们就可以开始对发光字的剩余部分开始进行组装了。

“The letter backs are attached by using either clinching, rivets, staples, or welding,” states Ondracek.

Ondracek说:“发光字的背面将使用铆钉、U形钉或是焊接的方法将材料牢固地拼合在一起。”

“Good quality channel letters are typically made with .063-inch aluminum backs,” says Sciortino. “They are also mechanically fastened to the flange of the return with aluminum rivets and a high-pressure clinch machine.” He emphasizes that attaching the backs mechanically is the preferred method.

Sciortino说:“使用0.063英寸的铝板材料可以制作出质量非常好的发光字标识,使用铝制铆钉和高压铆接机可以将铝板材料牢固地固定在标识的背面。”他强调,这是将材料安装在标识背部最好的方法。

“Some letters are stapled together, but this would be in the lower-quality category,” Sciortino adds. “Quality letters are then caulked inside the letter for weatherproofing, with siliconized caulk, which has much better adhesion components than just ‘painters caulk.’ The LEDs are then installed inside the letter with the provided double-stick tape.”

Sciortino补充说:“如果只是简单拼凑起来的发光字,通常质量就很差。为了制作出优质的发光字,应该对发光字内部进行防风防雨处理,再使用比普通‘油漆填缝剂’附着力更好的硅化填缝剂进行黏合,最后使用现有的双面胶带将LED安装在发光字内。”

“Proper LED installation does not stop there though,” Sciortino continues. “Companies performing good work will insure their LED install with 100 percent silicone to provide extra hold to the module. This is essential to make sure the modules don't fall off the lettetr back due to extreme temperature changes, which causes a poorly lighted product if the LED releases itself from the back of the letter.”

Sciortino继续说:“正确的LED安装方法并不止于此。一个优秀的公司应该确保他们的LED将使用100%硅胶进行安装,并提供额外的模组材料以备不时之需,这对于确保模组不会由于极端的温度变化而在发光字内部失去效用非常重要,因为LED光源从发光字背面亮起的产品,通常亮度效果都很不理想。”

The Letter Face

发光字的表面

Like the letter back, the face is necessary to close the opposite side of the letter. This is the element that allows the light to diffuse into an even illumination.

就像发光字的背面一样,发光字的表面也需要靠近其两边的边缘。这是为了使发光字能够散发出更均匀的照明效果。

“When making a plastic face channel letter this process has come a long way,” recounts Kane. “When I first started, we cut the backs by hand. Then we would layout the return with a tape measure and transfer the numbers to a 10-foot return that had a half-inch, 90 degree bend on one side. Then took a hand notcher and started to notch the return.”

凯恩回忆说:“我曾经有很长一段时间都在为发光字制作塑料外壳。当我第一次开始制作的时候,发光字的背面材料是由我自己切割的,随后我使用卷尺来测量光源的反射通道,并将测量出来的数据以10英尺为单位进行换算之后,每半英寸就将材料以90度的角度进行折弯,最后使用手工切角器对材料进行切角处理。”

Moving on to the face, Kane recalls, “The plastic face was cut from the letter that was flipped upside down. Using double-stick foam tape and a hand router with an offset bit, we cut the plastic.”

凯恩回忆到:“现在回想起来,当时的塑料表面材料是从翻转过来的发光字上切割下来的。我们还使用了双面的泡沫胶带和一个带偏置钻头的手动切割机对塑料进行了切割。”

Ondracek states that today “98 percent of sign faces are acrylic,” which allows for durability and lighter weight.

Ondracek表示,今天“98%的标识表面使用的都是亚克力材料”,这种材料耐用性较长且重量更轻。

“Good quality channel letters are typically built with 3/16-inch impact-modified plastic or polycarbonate,” suggests Sciortino. “Acrylic is fine as well as long as its 3/16-inch thick. You will find lower quality letters using 1/8-inch acrylic faces along with their .040-inch aluminum backs giving the letter a much flimsier character.”

Sciortino建议:“优质的发光字通常使用3/16英寸冲击改性塑料或聚碳酸酯材料制作而成,使用3/16英寸厚的亚克力材料也是不错的选择。但你会发现劣质的发光字通常使用1/8英寸厚的亚克力材料制作发光字的表面,使用0.04英寸的铝质材料制作发光字的背面,这样会使发光字更加的脆弱。”

When the face is in place and the letter has the look of being close to completed, “The last stop for this letter is the trim-cap,” states Kane. “This product allows you to fasten the plastic letter face to the return. It also allows you to have a creative design with your letters. For example, a red plastic face with gold trim cap and black returns will stand out a lot. While a red plastic face with red trim cap and black returns makes the face blend into the next letter. Forget about using a red return with a red plastic face and red trim cap, you’ll have a big red blur when driving by this sign.”

凯恩说:“当外壳安装好之后整个发光字就已经接近完成了,最后一步是对发光字进行铝边条的贴合。这个步骤能够将你的塑料标识外壳与标识的反射通道牢固的拼接在一起,同时使你的标识拥有一个富有设计感的外观。例如,当标识的正面塑料外壳选用的是红色,而相应的搭配也是金色的侧边装饰材料和黑色的反射通道内衬时,红色的塑料外壳就会显得非常突兀。而当侧边装饰材料的颜色是红色,反射通道内衬的颜色是黑色时,红色的塑料外壳就能与整体的发光字达到一个统一的状态。但是红色的标识反射通道内衬不能和红色的外壳及侧边装饰材料一起使用,当你驾车经过这种标识时,你往往只能看到一大块模糊的红色图案。”

Finishing Touch

画龙点睛

When it comes down to employing a channel letter bender versus manual bending for this type of work, it really isn’t a “good versus evil” discussion. It’s more about choosing what is most practical and offers premium advantages.

当你进行发光字处理的工作涉及到是使用设备进行折弯还是使用手动折弯的问题时,这实际上并不是一个关于对或错的讨论,而是要看哪种方法更实用,更有优势。

Ondracek points to “The cost savings, the quality of an American-made machine, and the service,” as key benefits of using a channel bending machine. It’s hard to argue that these elements aren’t enormously important to sign makers. Timeliness is also an essential advantage.

Ondracek指出“能够节约成本,拥有美国制造的设备质量和优质服务”是购买标识折弯机的关键优势,这些元素对标识制作者来说非常重要。及时性也是一个重要的优势。

“Retail sign companies appreciate that we can provide them with a superior product because of our skill level and state-of-the art equipment within a week or two, in turn keeping shops busy with selling and installing,” says Sciortino. “We are their manufacturing facility.”

Sciortino说:“由于我们拥有先进的技术水平和相关制造设备,零售标识公司很高兴我们可以在一两周内为他们提供优质的产品,这也使商店忙于销售和安装。我很高兴我们可以成为他们的制造工厂。”

Which properly illustrates how much equipment manufacturers and sign makers work together for the common goal of providing the best products. Kane shares in this belief and suggests to his customers, “Remember that when buying equipment, one day you will need tech support. Pick a company that has a great reputation for customer service.”

这恰好说明了设备制造商和标识制造商为了提供最佳产品的目标而共同努力。凯恩坚信这一点并向他的顾客建议:“请记住,在购买设备时,总有一天你需要技术支持。选择一家在客户服务方面享有盛誉的公司往往会事半功倍。”