UV-cure inkjet printing technology has steadily improved and developed since it was introduced more than a decade ago. With new developments in equipment technology, inks and media, UV-cure technology has matured and enjoyed rapid adoption in a number of markets over the past few years.

UV固化喷墨技术自十多年前推出以来就一直在稳步的改进和发展。随着设备技术、油墨以及媒介的新发展,UV固化喷墨技术已经逐渐成熟,并在过去几年中迅速在大量的市场中得到普及。

In the wide-format inkjet space, it has quickly evolved from mainly a flatbed inkjet printing technology to one that has become very versatile for a host of applications. Many believe that UV-cure technology offers graphics output providers the best mix of safety, reliability and material compatibility that the industry has seen in quite some time.?

在宽幅喷墨领域,它已经从主要的平板喷墨打印技术迅速发展成为广泛应用的多功能喷墨打印技术。许多人认为,UV固化技术为图形输出供应商提供了安全性、可靠性和材料兼容性的最佳组合。

As the industry continues to adopt UV-cure technology, an increasing number of print service providers are looking at high-speed UV-curing flatbeds and hybrids, as well as dedicated UV-curing roll-to-roll printers.

随着UV固化技术在行业的不断发展,越来越多的印刷服务供应商开始研究高速UV固化平板打印机和混合打印机,以及专业的UV固化卷对卷打印机。

Better ink formulations, new LED-based UV-cure lamps and new printhead technologies have come together to create a market that has made the segment much more cost-competitive with solvent inkjet printers. Today, most of the major wide-format equipment makers have some stake in the UV-cure inkjet market. And several printer manufacturers—including Mimaki, Roland and EFI—have become pioneering leaders within the newer LED-based UV-cure inkjet printer segment.?

更好的油墨配方、新型LED UV固化灯和新型打印头技术结合在一起,创造了一个能够与溶剂型喷墨打印机相比具有更高的成本竞争力的市场。如今,大多数主要的宽幅设备制造商都在UV固化喷墨市场中占有一定的份额。Mimaki、Roland和EFI等多家打印机制造商已成为新型LED UV喷墨打印机领域的先锋。

LED UV-Cure Technology Emerges

应运而生的LED UV固化技术

“The rapid adoption of UV LED curing technology is due to the inherent advantages of economics, new system capabilities, and environmental improvements,” says Chad Taggard, director of marketing and business development at Phoseon Technology, a UV cure-lamp manufacturer based in Hilllsboro Ore. “UV LED technology now has the performance to replace mercury vapor and metal-halide arc lamps used in virtually all UV-cure printing, adhesive and coating applications.”

位于美国俄勒冈州希尔斯伯勒市的UV固化灯制造商Phoseon Technology的营销业务开发总监Chad Taggard说:“LED UV固化技术的迅速普及归功于经济发展、新系统功能和环境改善等固有优势的延续,目前在所有UV固化打印、粘合和涂料应用中,UV LED技术拥有可替代水银蒸汽和金属卤化物弧光灯的性能优势。”

In fact, Taggard says, the adoption of LED-based UV-cure technology has become a major trend in the world of UV-cure inkjet printing, adding that the new technology allows printer manufacturers to offer lower operating costs, higher quality output and expanded printing capabilities. UV LED cure lamps, he says, have longer lifetimes, run cooler, contain no mercury, are less expensive to operate and generate no ozone, as do many conventional arc lamps. And Taggard is not the only one excited about LED-based printing technology.

事实上,Taggard表示,运用LED UV固化技术已成为UV固化喷墨打印领域的一大趋势,并补充说新技术使打印机制造商能够降低运营成本,提高产品质量并扩大打印功能。他说,UV LED固化灯寿命更长、运行温度低、操作成本低、不含汞、不产生臭氧,拥有许多能够和传统弧光灯相媲美的功能。而且Taggard并不是唯一对LED打印技术感兴趣的人。

“We are seeing more wide-format printer manufacturers considering and offering UV LED curing technology in newer devices,” says Paul McGovern, national sales manager at Mimaki USA, Suwanee, Ga. That’s because, “in addition to lower operating energy costs and faster start up times, LED cure lamps can last up to five years, and allow printing onto heat-sensitive substrates. This is a major influence in cost of ownership comparisons and is helping to move this segment to the forefront.?”

美国佐治亚州Suwanee市Mimaki USA全国销售经理Paul McGovern表示:“我们看到越来越多的宽幅打印机制造商正在考虑并在新设备中添加UV LED固化技术,这样做不仅能够降低能源运营成本和加速启动时间,LED固化灯使用寿命长达五年,并可以在热敏基板上打印。这将对打印成本产生重要影响,并有助于将这一细分市场推向前沿。”

“Still, conventional arc lamp technology continues to be a factor for the speed of curing in higher-speed printers equipped with multiple printhead arrangements. And conventional inkjet UV-cure lamp enclosures are now more compact and lighter, and are equipped with more efficient air and liquid cooling systems.”

“尽管如此,传统的弧光灯技术仍然是高速打印机为增加固化速度而配备多个打印头装置的一个因素。而现在的喷墨UV固化灯更加简洁轻便,并配备了更加高效的空气和液体冷却系统。”

Hiroshi Ono, group product manager, Roland DGA, Irvine, Calif., also agrees that recent developments in LED-based UV-cure lamp technology have been a real game-changer in that product category.?

加州欧文市Roland DGA集团产品经理Hiroshi Ono也同意上述观点,LED UV固化灯技术的最新发展成就已经成为该产品类别中真正改变实际规则的产品。

“LED-based UV-cure technology is revolutionizing the production process and is opening up new markets,” Ono says. “There is such a wide range of applications for UV-LED technology, the opportunities are endless. This is especially true when the technology is paired with other advanced features, such as integrated contour cutting capabilities and specialty inks.”

Ono说:“LED的UV固化技术正在彻底改变生产过程,并开辟了新的市场。UV-LED技术的广泛应用也带来了更多的机会。特别是当该技术与其他高级功能配合使用时尤其如此,例如集成轮廓切割功能和特殊油墨性能。”

Pros and Cons

优点和缺点

There are pros and cons for both approaches to cure lamps in today’s UV-curing printers. Experts say that conventional metal-halide and mercury vapor arc-type UV-cure lamps, though very effective, are expensive to replace, lose curing efficiency over time, and, when in use, release ozone into the work environment. Another downside to conventional UV-cure lamps is the intense heat generated that can warp or damage heat-sensitive substrates.?

如今的UV固化技术仍存在优点和缺点。专家表示,传统的金属卤化物和水银蒸汽弧形UV固化灯虽然效果显著,但是更换费用昂贵,并且随着时间的推移会失去固化效果,使用时会将臭氧释放至工作环境中。传统UV固化灯的另一个缺点是产生的强热会使热敏基板翘曲或损坏。

“Some inkjet manufacturers, in response to concerns about escalating costs and environmental issues, have gone to LED,” says Larry D’Amico, VP of digital imaging for Agfa Graphics North America, Ridgefield Park, N.J. “The major advantage would be that the cooler operating temperature provides greater media flexibility. However, if speed needs to be sacrificed in order to accomplish some of these goals, then it is not yet a legitimate alternative. As such, LED seems to be more popular on slower, lower-end devices.”?

新泽西州里奇菲尔德公园Agfa Graphics北美公司数字成像副总裁Larry D'Amico表示:“一些喷墨制造商为了应对成本和环境问题不断升级的担忧,已经转向投入进对LED的研究之中,LED的主要优势在于其冷却器工作温度能够提供更大的媒介灵活性。但是,如果为了实现一些目标,设备的速度不得不随之降低,因此它还不是一个完美的替代方案。因此,LED似乎在较慢的低端设备上更受欢迎。”

But Roland’s Ono states that newer LED-based UV-cure lamps are redefining the UV world. “UV LED lamps last up to 10,000 hours—10 times longer than conventional UV lamps—for dramatically lower operation and maintenance costs. They also emit very little heat, which makes them much more versatile with respect to the media they support. And while UV LED printers may take longer to print than conventional UV-curing printer systems, they require no warm-up time, so they are ready to start printing immediately after being powered on. They are also more energy efficient, and are completely ozone-free, making them a safer alternative to conventional UV-cure lamps. For these reasons, LED UV technology presents a much better overall value to the print service provider.”?

但Roland公司的Ono表示,LED的UV固化灯正在重新对UV领域进行定义。“UV LED灯的使用寿命长达10,000小时,是传统UV灯的10倍,大大降低了运营和维护成本。它们散发的热量非常低,这使得它们对于它们支持的媒介更加通用。虽然UV LED打印机可能需要比传统UV固化打印机系统更长的打印时间,但它们不需要预热时间,因此它们可以在打开电源后立即开始打印。它们也更节能,完全不含臭氧,使其能成为传统UV固化灯的更安全的替代品。由于这些原因,LED UV技术为印刷服务供应商带来了更好的整体价值。”

Ink Trends

墨水趋势

On the ink side of things, leading ink manufacturers see the great potential for the growth of LED-based UV-cure printing.?

在油墨方面,领先的油墨制造商看到了以LED为主的UV固化打印的巨大潜力。

“We have seen huge advancements in UV-cure technology in the last 10 years,” says Ken Kisner, President of INX Digital International, San Leandro, Calif. “At INX Digital, we’ve developed inkjet inks that work well on a wide variety of substrates. We have also produced very focused formulations that perform specifically well for certain substrates like glass, tile, plastic and corrugated packaging and others.”

加州圣莱安德罗INX数字国际公司总裁Ken Kisner表示:“我们已经看到过去10年中UV固化技术取得了巨大进步,在INX Digital,我们生产的喷墨墨水广泛使用于各种基材。我们还生产了一些非常重要并且用途广泛的配方,特别适用于如玻璃、瓷砖、塑料和瓦楞包装等基材。”

Kisner points out that his company has developed four specific base formulas of UV-curable ink: Stretch INX for wrap applications, Rigid INX for rigid substrates, Multi-Flex INX for hybrid applications and Flex INX for roll-to-roll materials.?

Kisner指出,他的公司开发了四种特殊UV固化油墨的基础配方:Stretch INX用于包装应用、刚性INX用于刚性基材、Multi-Flex INX用于混合应用、Flex INX用于卷对卷材料。

“Each of these categories can be aligned to the specific needs of a market and can be optimized for a set of substrates,” he says. Kisner says as markets for specialized inkjet inks continue to grow, they are seeing more dedicated machines for single purposes.?

他说:“这些类别中的每一个都可以根据市场的特定需求进行调整,并且可以针对一组基材进行优化。”Kisner表示,随着专业喷墨油墨市场的持续增长,他们看到更多专业的机器有了特定的服务用途。

“Advancements in LED curing technology allow these systems to have lower energy use and constant light output,” Kisner says. “Also important is the significant introduction of low-viscosity monomers that give ink chemists more latitude in their formulations. INX Digital is now able to develop inkjet inks with extremely high pigment density and to integrate other types of polymers to get unique attributes. Many of these new attributes lend themselves to fixed-array, high-speed printing.”?

Kisner说:“LED固化技术的进步使这些系统具有更低的能耗和恒定的光量输出,同样重要的是大量引入低粘度的单体,使油墨在搭配时拥有更大的自由度。INX Digital现在能够开发具有极高颜料密度的喷墨墨水,并集成其他类型的聚合物以获得独特的属性。许多这些新属性都适用于固定阵列的高速打印。”

McGovern is excited about new inks being developed for LED curing.?

McGovern对为LED固化开发的新油墨非常感兴趣。

“Today they are making LED cure UV inks that are chemically ‘matched’ to the waveform properties of the LED lamps that manufacturers are currently offering for inkjet printing,” he says. “These new inks allow much faster cure rates; and that enables much faster operating speeds and increased production without the need of post-curing methods (a second dose of UV light).”

他说:“如今,这些油墨与制造商正在制造LED UV固化油墨,目前他们为喷墨打印提供具有波形特性的LED灯进行化学‘匹配’。这些新油墨的固化速度很快,这样可以实现更快的操作速度和更高的产量,而无需后期的辅助固化(即二次UV光源照射)。”

EFI’s Faster LED Printer Speeds?

EFI的高速LED打印机

“In the early time, we introduced the EFI VUTEk GS3250LX,” says Ken Hanulec, VP of Marketing, EFI Inkjet Solutions, Meredith, N.H. The 126"-wide LED UV-curing printer is capable of 1,000 dpi and eight-color (plus white) speeds of up to 1,200 square feet an hour. “It’s a fully loaded, production-level hybrid printer that extends the range of supported substrates and features an innovative ink curing technology.?

新罕布什尔州Meredith的EFI喷墨解决方案市场营销副总裁Ken Hanulec说到:“早些时候,我们推出了EFI VUTEk GS3250LX,这是一款126英寸宽的LED UV固化打印机,它能够达到1,000 dpi和支持八色(包括白色)打印,速度高达1,200平方英尺/小时。”这是一款完全装载的生产级混合打印机,它不仅扩展了基材印刷的范围,并采用了创新的油墨固化技术。

Hanulec points out that PVS In-Store Graphics, located in Portland, Ore., installed the GS3250LX. According to PVS co-owner Wes Shinn, the company has already seen the benefits of their investment.?

Hanulec指出,位于俄勒冈州波特兰市的PVS In-Store Graphics安装了GS3250LX。PVS的老板Wes Shinn表示,这项投资对公司而言是非常有利的。

“We’ve been able to print on a much wider range of materials than ever before, opening up new opportunities we couldn’t pursue previously,” Shinn says. “Equally important has been the benefits of the new ‘Cool Cure’ technology. For example, with a much lower UV cure temperature, we have been able to use thinner styrene sheets at half the cost of what we previously were using, literally cutting our material costs in half. The key advantage is our ability to run different types of materials and thinner materials at a much lower cost without sacrificing any quality or speed.”

Shinn说:“与过去相比,我们能够对更广泛的材料进行印刷,这也让我们得到了很多以前无法得到的机会。同时新型的‘冷固化’技术也带来了诸多的好处。例如,在UV固化温度低得多的情况下,我们能够使用更薄的苯乙烯板材,成本只是我们之前使用的成本的一半,从而将材料成本降低了一半。关键的优势是我们能够以更低的成本运行不同类型的材料和更薄的材料,而不会牺牲任何质量或速度。”

Roland Opens 3-D Opportunities

Roland引领3D打印风潮

Roland’s Ono explains that UV inkjet ink traditionally has had a fairly rigid composition, which had limited the range of applications for it.?

Roland的Ono解释说,传统的UV喷墨油墨具有相当严格的成分制作标准,这限制了它的应用范围。

“Now, with more flexible inks, including Roland’s new ECO-UV S ink, UV inkjet technology not only supports a wide range of materials, but can effectively wrap a product’s contours, corners and indentations,” Ono says. “ECO-UV S stretches up to 220 percent, allowing it to conform to even the most complex surfaces. This new advancement is opening up several markets, including the design and production of packaging prototypes of virtually any organic shape. New ink formulations can even be used to print on vacuum forming materials commonly used in the production of control panels, automotive parts including dashboard components, and casing for electronic devices such as cell phones and MP3 players.”?

Ono说:“如今,类似Roland的新型ECO-UV S系列这样灵活的油墨,使UV油墨技术不仅能够支持多种材料的印刷,还可以有效地对产品的轮廓、角落和凹痕进行包装,ECO-UV S系列油墨的拉伸率高达220%,即使是在极其复杂的表面也能保持图形的原样。这一新进展可以帮助开辟多方市场,包括了大部分有机形状的包装原型的设计和生产。新的油墨配方甚至可以用于生产控制面板、汽车零件(包括仪表板组件)的常用真空成型材料,以及手机和MP3播放器等电子设备的外壳。

Ono says that Roland’s wide-format VersaUV inkjet devices support both flexible and rigid substrates, from PVC, leather, paper and board stocks to foils, plastics and films.?

Ono表示,Roland的宽幅VersaUV喷墨设备支持柔性和刚性基材,从PVC、皮革、纸张和纸板到箔、塑料和薄膜。

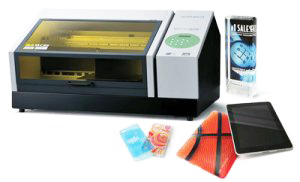

“This makes them well suited for applications ranging from signage, P.O.P. and interior décor items to packaging prototypes, labels and specialty graphics,” he says. “We introduced a flatbed VersaUV printer, the LEF-12, which prints directly onto three-dimensional objects, ranging from key chains, giftware and awards to smart phone covers and even laptop computers.”

他说:“这使它们非常适合标识、P.O.P.图形、标签和专业图形的室内装饰物品的打印,我们推出的一款平板VersaUV打印机LEF-12,它可以直接在三维物体上进行打印,比如钥匙链、礼品、奖品、智能手机外壳甚至是笔记本电脑的外壳。”

Agfa Expanding UC-Cure Options

Agfa为设备扩展UC-Cure的选择

Agfa doesn’t have a UV LED printer at this time, but is a major player in the UV-cure printer space with its :Anapurna line of UV-curing printers, and other printer products such as the :Jeti 3020 Titan unit.?

Agfa目前没有UV LED打印机,但他们的Anapurna系列UV固化打印机,以及其他打印机产品,如:Jeti 3020 Titan装置,都是UV固化打印机领域的主要参与者。

“Print service providers are looking for systems that can help them image corporate colors more efficiently,” D’Amico says. “For example, we expanded the color gamut in the :Jeti 3020 Titan to include orange and violet, giving it the ability to hit more spot colors.” ?

D'Amico说:“印刷服务供应商正在寻找能够帮助他们更有效地塑造企业色彩的系统。例如,我们扩大了Jeti 3020 Titan系列打印机的色域,包括橙色和紫色,使其能够打印出更多专色。”

He says that increases in quality and speed in UV-curing devices are starting to impact offset applications.?

他说UV固化设备的质量和速度的提高很容易影响平板印刷图形的应用。

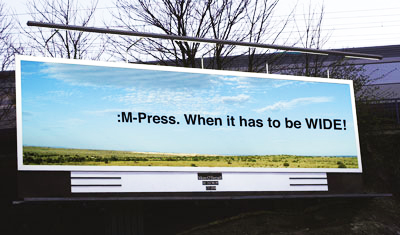

“The Agfa :M-Press Tiger, for example, is helping to create new opportunities in this new market,” D’Amico says. “Printers are discovering they can do some things more efficiently with digital technology. Both the :M-Press Tiger and :M-Press Leopard are unique in the speed and quality they deliver with Agfa’s low ink lay-down. It has the look and feel of an offset sheet making it very competitive in the short run end of this market.”

D'Amico说到:“例如,Agfa的M-Press Tiger打印机正在为这个新市场创造新的机会,打印机发现他们可以通过数字打印技术更高效地做一些事情。M-Press Tiger和M-Press Leopard这两款产品在速度和质量上都是独一无二的,它们采用Agfa的低墨水布局。及其具有的胶版纸外观和触感,使其短期内在该市场具有很强的竞争力。”

LED Printer Options from Mimaki?

Mimaki的LED打印选择

Mimaki USA was an early pioneering adopter of LED-based cure-lamp technology for the printers aimed at the signage and graphics marketplace. Some of their UV LED models include the JFX Plus Series Flatbeds (two bed sizes) and the UJF-3042 tabletop model as well as the Hybrid UJF-160 64-inch wide roll/rigid model. The UJF-3042FX can print white and clear, and has an automatic primer application function.

Mimaki USA早期就在标识和图形市场开创性采用了以LED为基础的固化灯打印技术。他们的一些UV LED打印机型号包括JFX Plus系列平板(两种机床尺寸)打印机和UJF-3042桌面型号打印机以及混合UJF-160 64英寸宽滚轴刚性型号打印机。UJF-3042FX系列可以打印出白色和透明色,并具有底漆自动应用功能。

Looking ahead to possible future equipment trends, McGovern sees E-beam (electron beam) curing systems as a possible “next big innovation” in this area. “If E-beam curing ever becomes more portable and less expensive, it is certainly a curing technology to watch. The E-beam curing devices used by commercial printers in printing press facilities are far too large, cumbersome and expensive to integrate into wide- or grand-format printers today. However, it is a great alternative to UV curing without the photoinitiators and chemistry of free-radical UV-curable inks which offers lower cost ink and fantastic flexibility.” ?

展望未来设备发展的大致趋势,麦戈文将电子束固化系统视为该领域可能出现的“下一个重大创新”。“如果电子束固化技术变得更加便携和实惠,它肯定能够成为一种实用的固化技术。商业印刷机在印刷机设备中使用的电子束固化装置太大、繁琐且昂贵,无法很好的融入到当今的宽幅或大幅面打印机中。然而,它是UV固化技术的一个很好的替代品,没有光引发剂和游离基UV固化油墨的化学性质,可以提供成本更低的油墨和极好的灵活性。”