Digital finishing is an essential part of any sign shops workflow. The right table cutter can eliminate bottlenecks to help your printing operation run smoothly and remain on the cutting edge.

数字化切割是任何标识一家工厂工作生产中不可或缺的重要组成部分。选择正确的切割机可以消除瓶颈,以帮助您的打印生产顺利运行,并保持产品的优质性。

The latest crop of flatbed digital die cutters can make life easier for sign and graphics businesses. If you are in the market for a new unit, finding the right machine for your shop will take some investigative research as well as asking the right questions.

最新的平板数字模切机可以使标识和图形业务的变得更容易。如果你想为你的标识工厂添加这样一台设备,那么建议你多采取一些调查研究以及问题,购买到适合你标识工厂使用的机器。

What are some features to look for (such as vacuum table, double-head models, router capabilities)? How much space do you need? How much power do you need for the motor? Which applications does this cutter excel in? How many tools do you need? What new services can you offer your customers? And, most importantly—how much money can you expect to spend? To help answer some of these questions, we spoke to some of the experts in this area and compiled some tips, product suggestions and other points you need to consider when shopping for a flatbed digital die cutter.

需要寻找哪些功能(如真空吸附台、双头工作模式、切割功能)?你需要多少空间?你需要多少动力来驱动马达?这个切割机擅长哪些应用?你需要多少工具?您能为客户提供哪些新服务?最重要的是,你能期望花多少钱?为了帮助回答其中的一些问题,我们与该领域的一些专家进行了交谈,并汇编了一些提示、产品建议和您在购买平板数字模切机时需要考虑的其他要点。

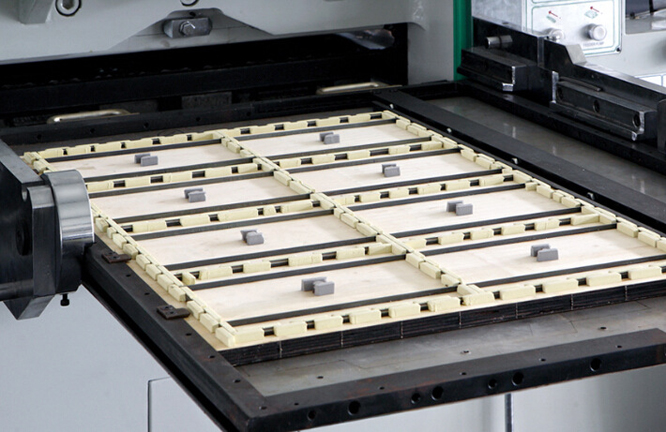

The BHS150 is designed for operation with the Zünd G3 and D3 cutter series. D3 dual-beam technology provides a significant increase in performance and thus offers maximum productivity. (Image courtesy of Zünd America Inc.)

BHS150设计用于Zund G3和D3系列刀具的操作。D3双光束技术显著提高了性能,从而提供了最大的生产率。(图片由Zund America Inc.提供)

Cuts Like a Knife

像刀一样切

“As the lines between print market segments continue to blur, the new normal for print service providers (PSPs) is to offer a full spectrum of products ranging from retail promotional graphics, decals and banners, to all types of displays, folding carton, and corrugated packaging,” says Beatrice Drury, director of marketing and communications Zünd America, Franklin, Wisconsin. “To meet this incredibly diverse range of finishing demands efficiently and therefore profitably, PSPs need specialized tooling and automated workflows that encompass all phases of production—no matter the specific finishing process or application.

市场营销和传播总监Beatrice德鲁里说:“随着打印市场细分之间的界限不断模糊,打印服务提供商(PSP)的新常态是提供全系列的产品,从零售促销图形、贴花和横幅到所有类型的显示器、折叠纸盒和瓦楞包装,为了有效地满足这一令人难以置信的多样化的精加工需求,因此,PSP需要专门的工具和自动化的工作流程,包括生产的所有阶段,无论具体的精加工过程或应用。

“Precisely for this reason, Zünd continues to focus on adding capabilities and workflow automation to our modular systems,” Drury adds. “For example, Zünd recently added laser capabilities to its already extensive range of tool options. At the same time, Zünd also introduced the over-head camera, which is a game changer when it comes to workflow efficiency. Instead of reading multiple register marks sequentially, which is the traditional registration method for flatbed cutting systems, the over-head camera captures all register marks at once.”

Drury补充道:“正因为这个原因,zund继续致力于为我们的模块化系统添加功能和实现工作流自动化努力,例如,Zund最近在其已经广泛的工具选项中增加了激光功能。同时,Zund还引入了摄像头,它在工作流程效率方面改变了游戏规则。无需按顺序读取多个存储标记(这是平板切割系统的传统注册方法),头顶摄像头可以一次捕获所有存储标记。”

At this year’s SGIA, Zünd added the BHS150, the latest generation of fully automated board loading/unloading/stacking—a system geared specifically to high-volume, industrial-level digital cutting/finishing. Paired with the dual-beam D3, the BHS150 is said to help deliver unprecedented non-stop productivity with 1.5m (5') stacking capacity at either end.

在今年的SGIA,Zund增加了BHS150机型,这是最新一代的全自动纸板装卸/堆垛系统,专门用于大容量、工业级的数字切割/精加工。与双光束D3配合使用,据说BHS150有助于提供前所未有的不间断生产能力,每端的堆叠能力为1.5米(5英尺)。

“What’s unique about Zünd’s modular machine concept is that a user can, for example, take the original digital cutting system they purchased for processing output from their flatbed printing device and adapt it to meet increased demand in, for instance, textile applications by adding a cradle feeder and Cut & Seal Laser Module,” Drury explains.

Drury Exp莱恩斯说:“Zund的模块化机器概念的独特之处在于,例如,用户可以利用他们购买的用于处理平板打印设备输出的原始数字切割系统,并对其进行调整,以满足增加的需求,例如:添加摇篮进料器、切割、密封激光模块、纺织应用。”

She adds another user may want to expand on their routing capabilities with the powerful 3.6kW router and automatic tool changer. And a third may be interested in adding fully automated loading and stacking capabilities with the new BHS150.

假如一个用户希望通过功能强大的3.6Kw切割功率和自动工具转换器扩展其路由功能。第三种可能对新款的BHS150机型的全自动装载和堆叠功能感兴趣。

“Zünd can accommodate all of these expansions—be it with a brand-new cutter configuration or an update to an existing one. New components can easily be added, thereby eliminating the need for purchasing additional equipment and maximizing the ROI on existing cutting systems.”

“Zund可以适应所有这些扩展,无论是采用全新的刀具配置还是对现有刀具的更新。可以轻松添加新组件,从而消除了购买额外设备的需要,并最大限度地提高现有切割系统的投资回报率。”

Esko’s Einar Ek says that the speed of your digital press could determine if a feeder and/or stacker is needed. (Image courtesy of Esko)

Esko的EinarEk说,数字打印机的速度可以决定是否需要进纸器和/或堆垛机。(图片由Esko提供)

Digital is a Game Changer

数字改变了游戏规则

Royce Owen, marketing director for AirMark Corp., Seattle, Washington, points out that flatbed technology is still relatively new when you compare it to traditional vinyl cutters, but digital technology of these models has moved rapidly and they have become a staple for popular finishing options due to their flexibility as well as the growth of rigid printer capabilities.

华盛顿州西雅图市Airmark公司的营销总监罗伊斯欧文指出,与传统的乙烯基切割机相比,平板技术仍然是一个相对较新的技术,但是这些型号的数字技术发展迅速,由于其灵活性和RI的增长,它们已经成为流行的精整选择的主要产品。gid打印机功能。

“Continuous-feed features and large cutting tables are both traits sign businesses should look for in a cutter,” he notes. “The former helps prevent bottlenecks by working through projects one right after the other. Essentially, you can queue the next board before previous ones are done. Continuous-feed cutters save time and help you complete more projects,” he suggests.

他指出:“连续进料特性和大型切割台都是企业应该在切割机上寻找的特征。”前者通过一个接一个地完成项目来帮助防止瓶颈。基本上,您可以在前一个板完成之前对下一个板进行排队。连续切刀可以节省时间,帮助你完成更多的项目,”他建议。

Owen says in addition to knowing what types of cutters are out there, you should also look at your operations.

欧文说,除了知道有什么类型的刀具,你还应该看看你的操作。

“The types of jobs you take on will determine your cutting needs. Will you be making product labels or large displays? Are you printing on vinyl or paper? Such factors determine the type of cutter you need along with the features it should have. For example, large products need space, which means a big flatbed cutter. As for material, get a cutter best suited for your medium. If you print on a variety of materials, you’ll need a cutter that can handle them all.”

“你从事的工作类型将决定你的切割需求。你要做产品标签还是大型显示器?你是用乙烯基还是纸打印?这些因素决定了你需要的刀具类型以及它应该具有的特性。例如,大型产品需要空间,这意味着大型平板切割机。至于材料,找一个最适合你介质的切割机。如果您在各种材料上打印,则需要一个能够处理所有材料的切割器。”

Owen points out that large flatbed surfaces are also popular in the industry. “As more wide-format printers continue to be introduced, cutters have gotten larger to keep up with the demand. Not only that, but with more space, your machine can handle complex contour cutting.”

欧文指出,大型平板床表面在这个行业也很受欢迎。随着越来越多的宽幅打印机的不断推出,切割机也越来越大,以满足需求。不仅如此,而且空间更大,您的机器可以处理复杂的轮廓切割。”

He explains that another thing to consider is that flatbed cutters have many different tool options for a wide variety of applications. “Flatbeds cutters have a versatile motorized tool head that can accept many different types of tools for a variety of substrates and applications — from fabric, wood, leather, and acrylic, to foam board, cardboard as well as roll material. The flexibility of the flatbed finishing system allows you to expand your business into new areas in many cases by just inserting a new tool.”

他解释说,要考虑的另一件事是,平板刀具有许多不同的工具选项,用于各种各样的应用。平板切割机有一个通用的电动工具头,可以接受多种不同类型的工具,用于各种基材和应用——从织物、木材、皮革和丙烯酸树脂,到发泡板、纸板和卷材。平板整理系统的灵活性使您可以通过插入新的工具,在许多情况下将业务扩展到新的领域。”

The Colex Sharpcut conveyer can be used for a variety of applications. (Image courtesy of Colex Finishing Inc.)

Colex Sharpcut输送机可用于各种应用。(图片由Colex Finishing Inc.提供)

Sizing Things Up

调整大小

Owen reports that the size of a system can be also be an issue for some smaller shops. “Many different sizes of flatbed cutters are now available. The flatbed cutters we sell have a rather small footprint and can fit into most shops, yet they are able to handle large panels of rigid substrate media. Rather than a vacuum bed, or units that employ pneumatic media advance clamps to hold down the hard media and continuously move it forward to accommodate large finishing jobs. In addition, the roll support and conveyer systems allow for long, continuous runs of flexible media.”

欧文说,设备的大小也是一些小的制作商家需要考虑的问题,现在有许多不同尺寸的平板切割机可供选择。我们销售的平板切割机占地面积很小,适合大多数工厂,但它们能够处理大块刚性基板介质。而不是真空床,或采用气动介质推进夹具来压制硬介质并持续向前移动以适应大型精加工作业的装置。此外,辊支撑和输送系统允许柔性介质长时间连续运行。”

He adds that the type of work that your shop will be handling should be something that should be researched—what size and types of media, length and tracking accuracy needs. “The number of functions included, and the level of quality built into the cutting table must be balanced against how much you are willing to spend.”

他补充说,你的工厂将要处理的工作类型应该是一些应该研究什么尺寸和类型的媒体,长度和跟踪精度需要的东西。“包含的功能数量和切割台内置的质量水平必须与您愿意花费的金额相平衡。”

Graphtec FCX4000 cutter series is an affordable cutting solution for small to medium print on demand jobs. It employs an electrostatic system to hold media. (Image courtesy of Graphtec America)

GRAPHTEC FCX4000切割机系列是一种经济实惠的中小型按需打印作业切割解决方案。它采用静电系统来容纳介质。(图片由美国石墨公司提供)

Accelerated Results

加速结果

Einar Ek, CAM solutions – pre sales at Esko, Miamsburg, Ohio, says that the customer’s job specs will determine the speed and power that is required.

Einar Ek,Cam解决方案–俄亥俄州,迈姆堡 Esko的售前人员说:“客户的工作规范将决定所需的速度和功率。”

“Let’s be clear that acceleration is what is really important. Cutting long straight edges fast is pretty simple. Stopping and going quickly around a number of small detailed cuts is a much greater challenge. For example, the Kongsberg cutting tables sold by Esko are engineered for production with no compromise between speed and quality over the entire surface.”

“我们要清楚,加速度才是真正重要的。快速切割长直边非常简单。停止和快速完成一些小的详细削减是一个更大的挑战。例如,Esko出售的Kongsberg切割台是为生产而设计的,在整个表面上速度和质量之间无懈可击。”

He says that the Kongsberg table’s focus areas are pretty versatile and include sign making, P.O.P. displays, protective packaging, short run corrugated and sample tables for packaging designers and converters. “Behind the many segments there are hundreds of materials from fine vinyl to heavy-duty paperboard or Plexiglas.”

他说,康斯伯格桌子的重点领域是相当多用途的,包括标识制作,P.O.P展示架,保护性包装,短期瓦楞和样品表面包装。“可以包含有数百种材料,从优质乙烯基到重型纸板或有机玻璃。”

When looking at how many tools are needed, Ek says that the answer goes back to determining what materials are being finished. “Normally, a customer would own three to six tools directed at their specific material selection,” he says. “For Kongsberg tables, it comes down to having the right portfolio of tool bits and blades to fit a customer’s requests. Esko offers a complete set of advanced quick-change tool heads that provide versatility, making it easy to set up the cutting table to process any material.”

EK说:“当查看需要多少工具时,可以追溯到确定正在完成的材料,通常情况下,一个客户会拥有三到六个针对其特定材料选择的工具,归根结底就是拥有适合客户要求的合适的工具位和刀片组合。Esko提供了一整套先进的快速更换工具头,可提供多种功能,使切割台易于设置,以处理任何材料。”

More Applications

更多应用程序

Ek points out that adding digital finishing to your process allows you to offer new and exciting applications and capitalize on some key trends such as:Personalization — “Every sheet can be printed differently. In the same way, every sheet can be cut differently.”

EK指出,在您的流程中添加数字整理可以让您提供新的令人兴奋的应用程序,并利用一些关键趋势,如:个性化-“每张纸都可以不同打印。同样,每一张纸的切割方式也不同。”

Creativity — “Straight-cut signs are basically commodities. Companies compete for this business on price. Digital finishing tables, with the right CAD design software, can allow print providers to offer creative 3D displays. This not only offers the ability to enjoy higher margins for unique work; it also allows a print provider to offer structural design services as a separate profit center.”

创意-“直线标识可以做成可以销售的商品。公司在价格上竞争这项业务。有了正确的CAD设计软件,数字精加工台可以让打印供应商提供创造性的3D展示。这不仅能够为独特的作品提供更高的利润空间,还允许打印商作为单独的利润中心提供结构设计服务。”

Interesting Materials — “New and more interesting materials that can only be finished on a CNC machine. For example, there is the ability to finish re-board for P.O.P. display projects, and most other materials used for signs.”

有趣的材料-“新的和更有趣的材料,只能在数控机床上完成。例如,有能力完成P.O.P展示项目的重新设计,以及大多数用于标识的其他材料。”

Just in Time Production — “In-house finishing can deliver quick delivery times from the print provider. In addition, the print provider benefits with greater capacity from faster throughput,” Ek concludes.

EK总结道:“准时生产-“内部精加工可以从打印供应商处快速交付时间。此外,打印提供商还得益于更快的吞吐量带来更大的收益。”

Making a Sharp Cut in Fabrics

在织物上做一个锋利的切口

Maureen Damato, sales dealer account manager at Colex Finishing, Elmwood Park, New Jersey, says the biggest trend in this category she is seeing is the ability to cut textiles and fabrics. “Sign and graphic shops should make sure that their cutter is capable of cutting textiles/fabrics for future workflow. For example, the Colex Sharpcut offers the SX3216 (10’ x 5’ with the ability to cut 4’ x 8’ boards and textile media up to 126" wide. The laser option is available to weld the edges to avoid fraying textile edges. The optional motorized rotary knife and heavy duty motorized rotary knife are available to cut textile/fabric.

新泽西州埃尔姆伍德公园Colex Finishing的销售经销商客户经理达马托说,她所看到的这一类别的最大趋势是能够裁剪纺织品和面料。“标识和图形工厂应确保他们的切割机能够切割纺织品/织物,以供将来的工作流程使用。例如,Colex Sharpcut提供SX3216(10’x 5’,能够切割4’x 8’板和126”宽的纺织介质。激光选项可用于焊接边缘,以避免织物边缘磨损。可选电动旋转刀和重型电动旋转刀可用于切割织物/织物。

Damato adds that the Sharpcut Flatbed Cutter offers a triple interchangeable tool head that includes a router for rigid material and two tool stations for a wide variety of tools for customer specific workflow. A six-zone energy efficient vacuum system with industrial vacuum motors for durability is also included.

Damato补充说,Sharpcut平板切割机提供了三个可互换的刀头,包括用于刚性材料的切割机和用于客户特定工作流程的各种工具的两个工具站。六区节能真空系统与工业真空电机的耐久性也包括在内。

She points out the Sharpcut offers three different router motors. “Each router offers spins up to 24k RPM available in 1.3hp, 3hp and 5hp. The horsepower of the router controls the maximum bit diameter and the depth of cut. In other words, the higher the horsepower the deeper the cut can be for each pass allowing the ability to cut thicker materials with fewer passes. Fewer passes means the cutter will be more productive and efficient while delivering clean, smooth edge quality.”

她指出Sharpcut提供三种不同的切割电机。“每台切割机提供高达24k转/分的转速,分别为1.3hp、3hp和5hp。切割机的马力控制最大钻头直径和切削深度。换言之,马力越高,每次通过的切割深度越深,允许以较少的通过量切割较厚的材料。较少的焊道意味着切割机在提供干净、光滑的边缘质量的同时,将更加高效和高效。”

She says the Sharpcut tool head can cut foamboard, coroplast, PVC, corrugated plastics and more while the more powerful router head can cut Dibond, acrylic, wood and aluminum up to 2-1/2 inches-thick. “Colex also offers the EngView Library software suite that contains more than 1,500 resizable templates for boxes, P.O.P. and trade show furniture.”

她说,锋利的刀头可以切割泡沫板、Coroplast、PVC、波纹塑料等,而更强大的刀头可以切割2-1/2英寸厚的dibond、丙烯酸、木材和铝。“Colex还提供EngView库软件套件,其中包含1500多个可调整大小的盒子、P.O.P.和贸易展览家具模板。”

Damato adds that the Sharpcut standard 5’ x 10’ package includes the triple interchangeable tool head, an energy efficient six-zone vacuum system and vision registration, and includes installation, on-site three-day training and one-year warranty on parts and labor.

Damato补充说,Sharpcut标准5’x 10’套装包括三个可互换工具头、一个节能六区真空系统和视觉注册,并包括安装、现场三天培训和一年的零件和劳动力保修。