The word “plastic” used to have very negative connotations. It meant cheap, fake and fragile. But that has all changed. Our current state of consumer goods would not be possible without modern plastics. Most of the items manufactured today make use of the easy conformability and durability of plastic.

提起塑料制品,人们一贯有着非常负面的印象,因为它有着廉价,虚假和脆弱这三个不被看好的弱点。但是现在一切都改变了。就当前状态来说,消费品的制作是离不开塑料板材的。正是由于塑料制品本身所具有的的稳固性和耐久性这两大特质,所以今天大多数制造项目愿意拿塑料板材来做文章。

The sign industry is a premier example of the importance of plastic. Its light-transmissive qualities make it ideal for illuminated signs. Plastic’s light weight makes it perfect for indoor displays and its ease of molding and forming fit perfectly for the graphics industry.

最能体现塑料的重要性的例子是标识行业,其透光特性使它成为理想的发光字制作板材的不二之选。塑料的重量轻,且易于成型,所以在图形展示行业中,非常适合于做室内展示。

Acrylic 亚克力板材

The original sign sheet was acrylic. The most common form of this ubiquitous material is the extruded sheet. Liquid plastic is extruded into long rolls of plastic, which are converted into the standard sheets we see so often today. The more expensive cell cast acrylic is poured into individual sheets in a mold. Cell cast plastics are easier to form and have superior optical clarity as compared with less expensive extruded acrylics.

最开始的标识板材就是亚克力板材。这种普遍存在的材料最常见的形式是挤出型板材。液态塑料被挤进长形的塑料卷中,然后被转换成我们今天所熟悉的标准板材。最贵的槽模浇铸被注入到单独的板材模具中。与较便宜的挤出型亚克力板材相比,槽模浇铸更易成形,且具有优越的光学清晰度。

The relatively low cost of acrylics and their ease of use have made them the main plastic to use for indoor signs, especially backlit or high-end signage. Acrylics can be easily thermoformed, heat bent and glued. They are, however, somewhat brittle and will break on impact, especially in the cold. This makes them less suitable for outdoor signage.

亚克力板材具有相对较低的成本和很强的易用性,然而由于它们本身具有较脆的缺陷,在低温条件下易破损,所以这使得亚克力板材不太适合室外展示,因此室内展示便成为了最佳选择。同时,亚克力板材在被加热后可以很容易的成型、弯曲和胶合,所以很多背光标识和高端标识更倾向于选择这种材料。

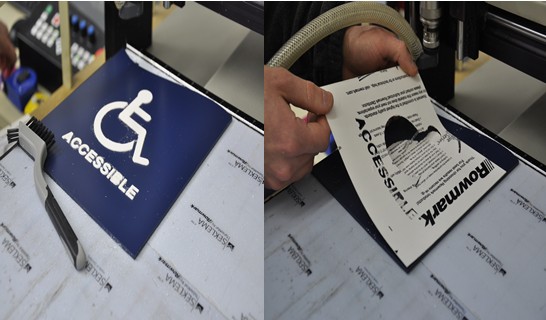

Rowmark ADA signage product utilizes an adhesive backed acrylic that can be cut to shape, then adhered to the acrylic substrate. (Image courtesy of Rowmark)

Rowmark ADA标牌产品在亚克力背面利用粘合剂可切割成形,然后粘合到亚克力衬底上。 (图片Rowmark提供)

The advent of LED lighting technology for illuminated signage brought benefits as well as challenges. When first introduced, the small, energy efficient light sources provided long-lasting, high intensity illumination, but signs tended to look like thousands of pinpoints of light instead of an evenly illuminated graphic. In order to solve this problem, new diffusion techniques had to be invented and acrylics became available from different manufacturers using different technologies to solve the problem by diffusing the light more evenly across the plastic surface.

LED照明技术给发光标识带来了极大的好处,当然也有很多的挑战。在它前期应用的时候,高效节能光源可以提供持久的、高强度的照明,缺点是,不能很好地聚光。为了解决这个问题,我们发明了新的扩散技术,如导光板等。它们可以将光聚焦在一个发光的中心,更好的呈现发光的效果。不同的厂商使用不同的技术来解决这一问题,使光更均匀的扩散在板材的表面,从而达到相应的效果。

There are also lots of specialty applications for acrylics. "Edge-lit" technology or "edge glow" is an effect created when light focusing on a material's edge is evenly diffused across its surface. Rowmark’s ColorHues product provides the light transmissive benefits of glass in a lightweight, scratch resistant material that includes 35 bright colors. The translucency of the products make them well suited for edge lighting applications.

对于亚克力板材来说也有许多特殊应用,如“侧光”技术或“边缘发光”技术,就是说,即使光聚焦在材料的边缘,也可以达到均匀弥散,分布在其表面的效果。以美国罗马克公司发明的 colorhues产品为例,就可以很好的解决光的透视性问题。colorhues可以出现35种很明亮的颜色,也可以实现耐磨防刮型玻璃材质,有明显透光的效果。产品的半透明性使整体内打光有很强的操作性,非常适合于边缘照明应用。

Engravable plastic stock usually comes in layers of different colors. Engraving through the top layer exposes the bottom layer in a contrasting color. Now available specifically for backlighting applications is Rowmark’s two-ply Color ColorHues EFX product line, featuring a black cap over translucent colors. Engraving through the black cap leaves the brilliant translucent colors showcased on the opaque black background.

Durability has always been a major Achilles heel with acrylic plastics. However, today’s strengthened acrylics have partially solved that problem by increasing the outdoor durability of the product. But of course the price goes up and it is still not as strong as polycarbonate.

在雕刻中使用的板材,采用在顶层雕刻过程中暴露出底层颜色的手法,通过不同的颜色分层,在层与层之间形成对比色。现在市面上专门针对背光标识应用的有美国罗马克公司的ColorHues EFX产品线,使用黑色的顶,覆盖在半透明的板材上来产生对比色。亚克力板材的耐久性是一个很具争议的问题,本身是很稳固的,但是由于化学材料等原因,并不能达到人们对它的期望。然而,随着现在技术的加强,革新后的亚克力板材已通过提高户外产品的耐久性解决了这个问题。它的成本上涨了,不过在结实度上仍然比不上聚碳酸酯。

Polycarbonate 聚碳酸酯板

Polycarbonate is the king of tough. It is used for everything from riot shields to jet fighter windows. This extreme durability originally came at a price. Early polycarbonates yellowed quickly and were prone to scratching, but those days are gone. The first commercially viable polycarbonate was patented by Bayer in 1953. Bayer MaterialScience now bonds a UV topcoat directly onto the polycarbonate during the extrusion process as an integral layer. They are so confidant in their product that Bayer Makrolon sheets have a 10-year guarantee against breakage or loss of light transmission.

聚碳酸酯是最坚韧的,它可用于一切地方,比如防暴盾牌或者喷气式战斗机的窗户。俗话说,物极必反,这种极端耐用性肯定是有一定弊端的。早期的聚碳酸酯泛黄速度较快,且容易产生划痕,因而在实际应用中并不能达到理想的效果。但随着技术的不断完善,直到1953年拜耳凭借可行性强的聚碳酸酯在商业领域申请了专利,这种材料才有了一丝转机。拜耳材料科学有限公司长期致力于研究该项技术,在原来挤出的过程中,加入了光疗表层技术。他们在这类产品中是非常有自信和权威的,拜耳的Makrolon类型的板材在光线传输使用中可以保证十年产品品质不变。

Polycarbonate maintains its strength after thermoforming.聚碳酸酯热成型后保持其强度。

Another problem traditionally experienced with polycarbonates was the soft surface that scratched easily. Using Makrolon as an example again, we can look at their two solutions. One is to coat the polycarbonate with a gloss, scratch-resistant surface and the other solution is to offer a matte, textured surface. The textured surface is the strongest defense against scratching and has the added bonus of making fingerprints hard to see. It is, however, not as optically clear as the gloss products. The gloss scratch resistant coating is not as tough, shows fingerprints easily and is subject to glare, but features enhanced clarity and color brilliance.

同时也会面临一个问题,传统的经验告诉我们聚碳酸酯的表面是软的,很容易刮擦。继续用聚碳酸酯来举例子,我们可以做一个实验,一是用表面光泽的产品;二是用磨砂后表面纹理化的产品,磨砂后的产品可抵抗划痕 ,且在指纹辨认方面有突出优势。实验结果表明,还是光泽产品略胜一筹。光泽产品有耐刮,涂层不硬,容易显示指纹,有眩光,且有增强清晰度和色彩亮度的优势。

Polycarbonates are also very easy to form and shape. They can be cold formed in a break, unlike their acrylic cousins which just shatter. Polycarbonates also maintain their strength after thermoforming and have a faster cool-down time than acrylics, reducing production times. Their excellent forming characteristics mean uniform light diffusion, even with deep draws or complex corner shapes. Makrolon LD sheet is especially designed for LED lighting with increased diffusion and high heat resistance, which allows the facials to be closer to the lights, which in turn means thinner sign cabinets for a more sleek, modern appearance.

聚碳酸酯板材是很易成形的,它们可以在冷冻中的过程中使自身材质发生化学变化,区别于亚克力的物理变化。聚碳酸酯在热成型后还可保持强度,并且有比亚克力板材更快的冷却时间,提高了生产效率。这就意味着在成形过程中,光可以很均匀打在上面,使板材很有光泽,达到了想要的视觉效果。拜耳的Makrolon LD板材是专门为LED照明设计的,采用了增强光的扩散性和耐热性的方法,所以说这个板材在LED照明产品中发挥了很大的作用。

And just when you thought that you’d heard all the advantages of polycarbonate, there’s more. While acrylic traditionally just comes in a few stock sheet sizes, polycarbonates come in sheets and/or rolls. For example, Bayer MaterialScience offers sheets as large as 75” x 125” and their roll stock is available up to 100” wide!

你会听到聚碳酸酯的所有优势,当然还有更多。而传统的亚克力尺寸却很小,聚碳酸酯板材却是用卷来计算的。例如,拜耳材料科技有限公司可以提供板材的尺度在75”×125”左右,可它们卷式宽的部分可高达100”!

In Summation 花开两朵 各表一枝

So acrylics are less expensive than polycarbonates, but not as strong. Both products form easily, but acrylic bonds better. There are a wider variety of specialty acrylic products but polycarbonate comes in larger sign-friendly sizes. Is one better than the other? Well, that depends on what you want to do with it.

最后来总结一下亚克力与聚碳酸酯的各自优缺点。第一,从价钱上来讲,亚克力较便宜;第二,从耐用程度上来讲,聚碳酸酯更耐用一些。第三,从使用方法上来说,聚碳酸酯需要用单独板材成型浇铸,而亚克力是将产品结合起来使用会更有优势,且产品联结焊接在一起之后,粘合度会更好。两者共同点是都易成型。整体来说,专业型的亚克力的范围更广泛一些。如果要问两个产品哪个更好?当然这要取决于用户您自身的体验以及用途了,实践是检验真理的唯一标准,大家心中各有一杆秤,您自己评判吧。