Even though we have a small staff, it is not unusual that I find myself out installing signs of all kinds solo -- one man, one sign, and a need for three hands or even an eight-foot-long right arm. Very often there is an easy way, and a hard way, and I try diligently to find the easy way if I can. For this month’s Shop Talk we’ll look at a couple of handy shop-made items that make one-man installs go smoother and faster, and an idea or two on making a one-man bucket more useful and user friendly.

虽然,我们有一个小小的团队,但不同寻常的是我自己一个人可以安装任何种类的小贴士或者提示。通常情况下,它们是需要2~8个人才能完成的。因为我有独特的安装技巧可以免去很多劳动力。任何安装方式相比之下都有简单和复杂之分。我在日常工作中立志于寻找最简单便捷的安装方式。今天我就和大家分享几个一个人安装的案例,让小规模的标识公司的安装项目更简单更快捷。

Often the signs or even parts of signs to be installed on a wall of some kind are fairly large. Full 4’ x 8’ panels are typical, and sometimes the panels are even 10’ long, which is certainly clumsy for a single person to handle. The common sense solution is to make some kind of ledge or even a row of screws or something to hang the panel or panels on temporarily. But putting extra holes in a client’s building, and below the sign where they may show, isn’t the best idea. If a ledge or temporary bracket is secured behind the sign, then it may be a pain to remove without loosening the sign.

有些标识或者标识的一部分要安装在一个面积很大的墙上,最典型的是4’ x 8’规格的基板,有时是10’长的管道,一个人安装是很难完成的。常规的解决办法往往是制造一个壁架或者一排螺丝之类的用来暂时悬挂基板或者广告。这样一来就会在客户的建筑上留下钻孔之类的痕迹,在标识广告拆卸之后就会显现出来。如果标识后面的壁架或者支架足够牢固的话,日后拆掉它们的工作又是一件不太容易的事。

Some installs are done by securing aluminum tubing strips to a wall with anchors and screwing the sign panels to it. The same “ledge” pieces or brackets are used to temporarily support the panels and they hang on small strips of aluminum strategically placed on the tubing.

Some installs are done by securing aluminum tubing strips to a wall with anchors and screwing the sign panels to it. The same “ledge” pieces or brackets are used to temporarily support the panels and they hang on small strips of aluminum strategically placed on the tubing.

有的安装过程是用铆钉将铝管固定在墙上,然后将标识或者广告固定在铝管上。那些悬挂在铝条上的支架只是暂时起固定作用。

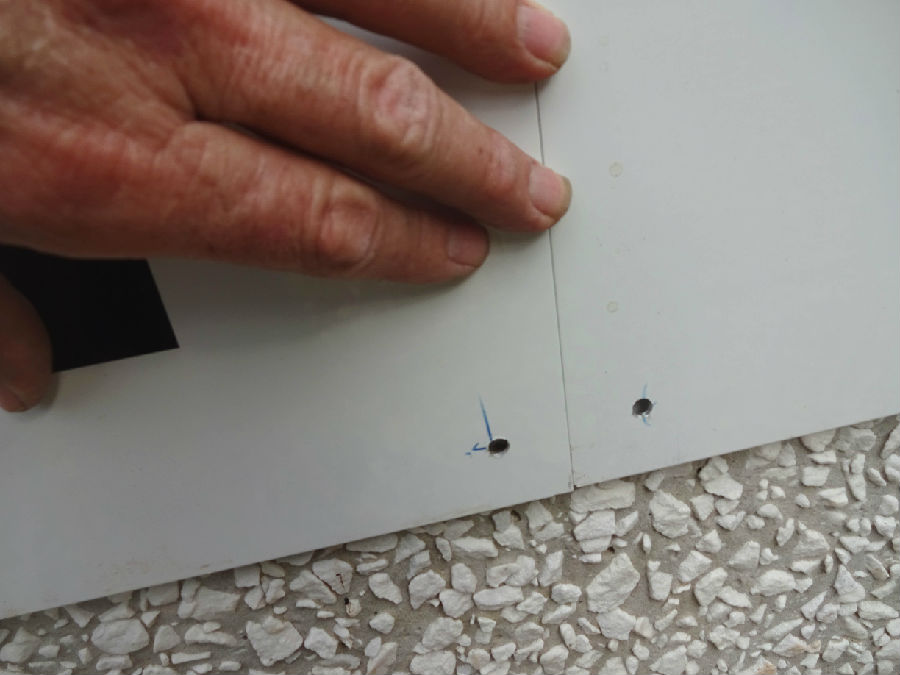

Well, there is a simple solution, and it is shown in the accompanying photos. Brackets or short ledge pieces can be made that clip over strategically placed strips of sheet metal. The strip is hidden totally behind the sign and left in place after the sign is installed. With this method, the sign can be totally attached to the wall across the top edge of the sign, and once that is accomplished the sign is only slightly pulled away from the wall at the bottom. The bracket is easily disconnected from the sheet metal strip, and the strip is left harmlessly behind the sign. The temporary ledge piece is saved for the next installation.

便捷的安装方式当然存在,如文中图片所示。支架或者短壁架可以用金属片来替代。金属片可以完全隐藏在标识背后。用这种方法,标识可以完全贴在建筑表面。一旦标识完成它的使命,可以把它直接从底部移开。金属支架很容易拆卸,毫无痕迹。而且临时壁架可以重复使用。

Once the sign is attached all along the top edge, the bottom edge can still be pulled outward enough to clear the temporary brackets.

Once the sign is attached all along the top edge, the bottom edge can still be pulled outward enough to clear the temporary brackets.

如果标识的顶端已经固定,下面的边缘还可以掀起足以清理所有的临时支架。

This works very well if mounting the sign to a metal building wall as the gaps between the ribs make an offset to hang the ledge pieces in. Sometimes I mount flat signs on lengths of 1” aluminum tubing so the sign is slightly offset from the wall, in which case some extra pieces of sheet metal a bit wider than the tubing are used to hang the temporary “ledge” brackets on. The temporary brackets won’t move with the weight of the sign panels on them, but once the sign sections are secured along their top edge, the bottom edge is pulled out slightly and the brackets are easily and instantly removed. No tools are required since gravity is the only thing holding them in place anyway.

在金属墙壁上安装这种贴士标识时这种方法很有效,壁架正好可以弥补标识与墙体之间的空隙。有时我在1英寸长的铝管上安装旗帜标识时会发生倾斜,标识与墙面之间就会形成缝隙。此时,只需要一个比缝隙宽一点的铁片就可以创建一个临时的壁架支架。有标识基板的重量在上面,临时支架不会轻易移动。轻轻向上一抬,标识和临时支架就可以拆卸了。只要有重力在,就不需要其他的固定措施。

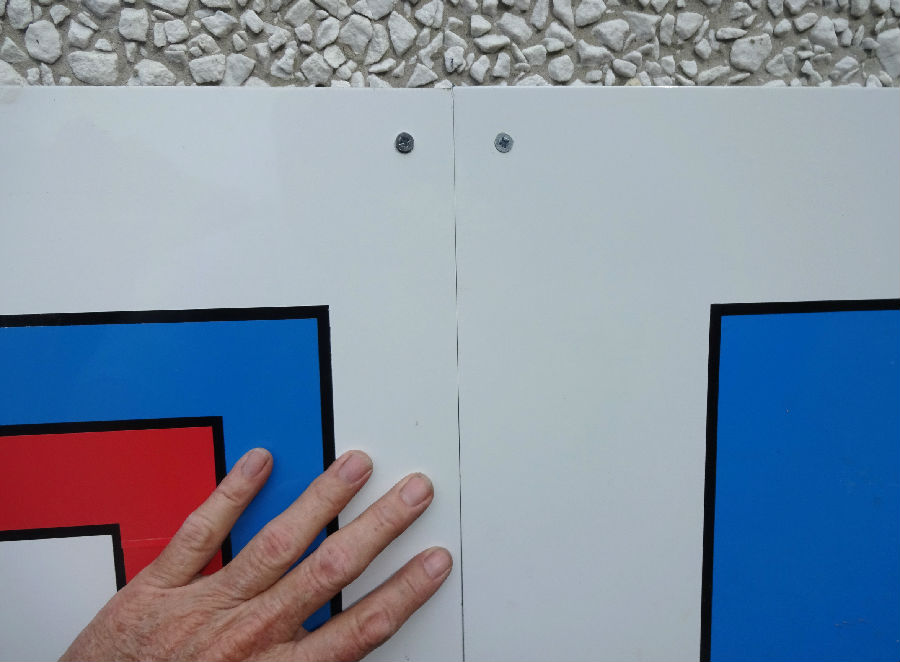

Another type of challenging installation, requiring more hands and longer arm reach than a single sign person comes equipped with, is a large two panel sign on a masonry wall with a center joint that needs to be perfect. I have on numerous occasions had to join 8’ long or even 10’ long panels, and getting them exactly level and perfectly seamed together working alone is a real chore. An installer can’t be at one end of a sign section and at the center where the two join at the same time, and an error of a fraction of an inch will show up as a gap or overlap in the center joint.

另一个很有挑战性的安装过程是要在石砌墙上安装两个镶嵌在一起的标识,这种标识的安装过程需要更多人手和更大的手臂范围,很多8英寸或者10英寸长的基板需要安装,想让它们保持水平并完美契合着实是一件繁琐的事。施工者不能只站在标识的一段应该站在两块基板的契合点,任何一端一英寸的差距都有在契合点形成很大的缝隙或者重叠。

A sheet metal joint perfectly matched at the top of the joint and the same perfect match at the bottom isn’t that easy without extra hands and eyes.

A sheet metal joint perfectly matched at the top of the joint and the same perfect match at the bottom isn’t that easy without extra hands and eyes.

一个人想让标识板的连接处上下衔接一致,完美契合是很难做到的。

A very slight error in leveling the end of the sign will produce a noticeable crack at the joint, unlike this sign here.

A very slight error in leveling the end of the sign will produce a noticeable crack at the joint, unlike this sign here.

每一块板有稍微的倾斜都会在接口处形成明显的缺口。

These two sign panel “cam-levelers” are shop made and are tensioned with a wing nut on the front. The pivot hole is off-center making it work like a cam.

These two sign panel “cam-levelers” are shop made and are tensioned with a wing nut on the front. The pivot hole is off-center making it work like a cam.

这两个调整脚架是我提前做好的,它们的前端有一个翼状螺帽,它的中心点不在圆盘的中心位置。

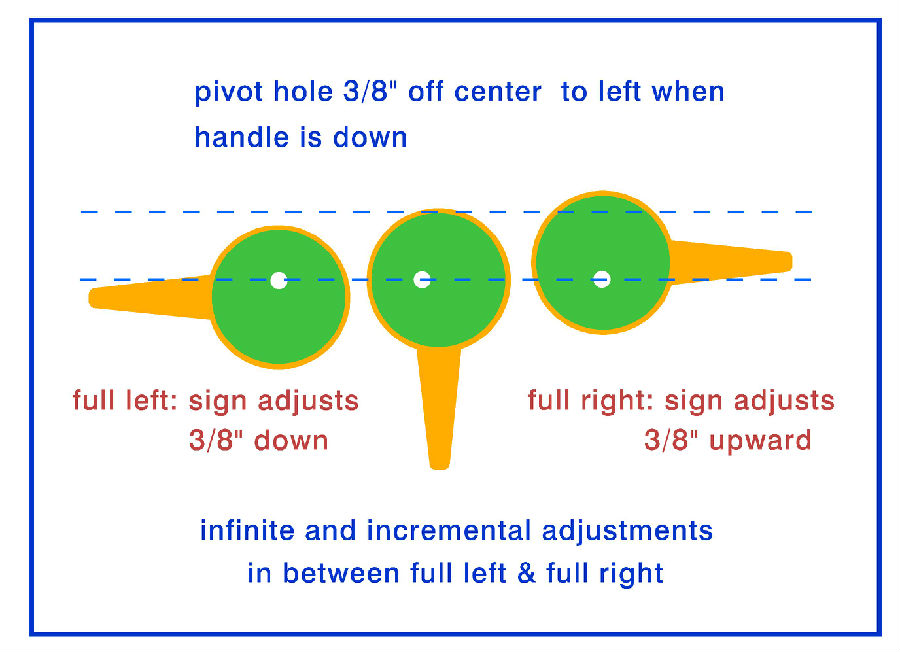

But, I have another homemade device that solves this problem easily, holding the panels level and making them micro-adjustable so the level attempt is perfect every time. It is basically a disk with a handle, which has a slightly smaller disk right behind the first, and these are attached to a mount using a single bolt that is exactly 3/8” off from center to one side when the handle points straight down.

不过,我有一个自制的小设备可以轻松解决这个问题,它可以让标识基板保持水平并且在小范围内可以调整,这个方法屡试不爽。它主要是由一个小圆盘和一个调节器组成,调节器略小于正前方的圆盘。它们分别安装在距离中心位置3/8英尺的地方,用来调整和固定两块基板。

The illustrations show this better than my description, but a sign panel, either sheet metal or aluminum laminate, is allowed to rest on this device at its end (away from the joint), and is attached to the wall with one screw and anchor at the top corner near the joint only. Turning the handle left or right will adjust the end of the sign up or down incrementally and controllably and hold it in whatever position until all pilot holes through the sign and into the masonry have been drilled. Once the pilot holes are located, the panels are taken down, the “sign levelers” are removed. All the holes are re-drilled for anchors, and the anchors are put in place. With the anchors located precisely, the permanent install of the panels should go smoothly and the joint where the sign panels connect should be spot on with virtually no adjustment required.

文中的插图胜过任何说明,例如铝片之类的金属广告板都可以在底端用这种工具固定,在节点旁边用螺丝钉即可固定在墙上。左右旋转调节器即可上下移动广告板,在墙壁打孔之前任何位置都可以调整。钻孔完成后,广告板的位置就固定了。锚钉的位置定位准确,广告板的安装过程就会很顺畅,每个钉子都在最恰当的位置上。

A helpful trick is using an adjustable cam-action support at each end, which can be lowered or raised very incrementally to line up the panels true and straight for an accurate joint without the benefit of a helper.

A helpful trick is using an adjustable cam-action support at each end, which can be lowered or raised very incrementally to line up the panels true and straight for an accurate joint without the benefit of a helper.

一个有效的做法就是在标识板的两端安装一个自制的小装置用来固定和上下调节标识板,便于寻找最精确的位置。

Not all of our installs are on the ground, of course, and working out of our manlift or our old Ford bucket truck is normal procedure. But, as I have mentioned before, what isn’t normal for bucket truck work is having any real accommodations in the bucket for tools, hardware, screw guns or just about anything other than the operator himself (who has to carry everything in his shirt pocket or on his tool belt, I suppose). For me, solving this situation is important since we actually do have work to do, and need things to do the work with, including drills, hardware, screws, rivets and rivet guns, levels, hand tools and more.

并不是所有的安装步骤都在地面上进行,升降机或者铲车上安装也在正常程序之列。但是,铲车上一般不会有五金器具,螺丝刀等常用的工具,即使有也不会比安装工人口袋里的工具多。解决这类问题是保证效率的关键,一般需要准备的工具有钻头、五金器具、螺丝刀、铆钉、铆钉枪、尺子等。

The photos show how I’ve configured out little bucket truck, and recently made it even more handy to work out of. When I bought the truck it had belonged to a local sign company for several years, but I suppose they were happy to just hold drills with their knees and put everything else in a tool belt or shirt pocket. Personally, I want everything in easy reach, and I carry up two or three drills and drivers at a time to eliminate wasting time changing bits, sockets, countersinks and so forth.

如上图所示,我的小斗卡车为我的工作带来很多便利。在我之前这辆卡车已经为一家大型标识公司服务了很多年。但我觉得那时他们应该更喜欢把工具放在自己的膝盖上或者是腰间的口袋里。我个人认为,任何事情都应该以最简单的方式完成,我通常为了节省时间会同时打开两到三个电钻,以免换插头、钻头等浪费时间。

This little drawing shows how rotating the handle to the left lowers the end of the sign, and moving the handle to the right will raise it, incrementally and with deliberate precision.

This little drawing shows how rotating the handle to the left lowers the end of the sign, and moving the handle to the right will raise it, incrementally and with deliberate precision.

这是一个原理示意图,它展示了向左旋转降低标识末端,向右旋转可抬高标识的工作原理。

The arrangement shown in the photos works very well, and has a slot or place for just about everything, from screw drivers to hammers to fasteners, brackets and anything else I will be needing. In the bucket with me are simple U-bolts, which come in handy as well for holding screw guns, levels and the like. The trays shown were made from scraps of .063 aluminum, which was cut to shape on a CNC machine. They were assembled with rivets and also mounted to the bucket with the same hardware.

图片中的安排方式很有效率,小空间内井然有序,从螺丝刀到锤子再到零部件都是我即时使用的工具。有了这辆小斗卡车,我的工作容易了很多。铲车的车斗类似于一个托盘,是由.063型铝材经过CNC切割机加工成形,然后再用铆钉固定。

The part in the preceding photo is at the upper right in this image, providing more safe and handy places to put tools. It connects to a shop made tray that holds three screw guns, batteries, hardware and more. A bucket with no place to put things is a major time waster.

The part in the preceding photo is at the upper right in this image, providing more safe and handy places to put tools. It connects to a shop made tray that holds three screw guns, batteries, hardware and more. A bucket with no place to put things is a major time waster.

在卡车上增加一个托盘用来放置常用的工具,包括螺丝刀、电池、五金等。井然有序的工具摆放也可以缩短工作时间。

As might be assumed, wasting time is not my intention when I go out on sign installs, and I don’t waste manpower either. So, very often there is just one set of hands out on a job, and those hands are mine. I want to get them most work from them as I can, as fast as I can, and if I am accomplishing that, this old sign guy is having a really good day.

假设,我在标识安装的过程中既不浪费时间又能节省人力,那我一个人就可以胜任绝大多数的安装工作。我想节省更多的劳动力,更快速地完成工作,如果我的精力允许的话某些老一辈的标识安装从业者就要提前退休了。