Cutting and finishing have always been a major part of the overall production process for sign shops and print service providers (PSPs). With the vast array of digital printing equipment and media choices currently available over the past decade, many print providers are now finding that cutting and finishing options are no longer a one-size-fits-all solution.

一直以来,切割和精加工技术已经成为标识店铺和喷印服务商生产过程中的重要组成部分。在过去十年里,已经出现了多种数码喷印设备和可用介质,许多喷印提供商意识到,切割和精加工不再是一个万能方案。

Depending on the project and substrate being used, shops can now choose from a range of routers and flatbed cutters with various cutting heads. In addition, automation and physical handling of the final product is also being looked at more closely since each product and system provides a different set of workflow possibilities.

根据所使用的介质,标识店铺有多种选择,包括不同种类切割头的数字切割机和平板切割机。另外,由于每种产品和系统都有一套不同的工作流程,因此终端产品的自动化和物理处理过程也被密切地关注着。

In the past, CNC routers clearly dominated this category but now other digital cutting solutions are coming to the forefront.“The flatbed router/cutter segment is becoming an important new growth area in the wide-format printing market,” writes Steve Urmano—director of InfoTrends' Wide Format Printing Consulting Service—in a recent White Paper on wide-format cutting devices.

过去,CNC数控设备在这个领域明显占据主导地位,但是目前数码喷印技术却备受关注。美国赢船公司宽幅喷印资询服务部门主管,史蒂夫·尔马诺在最近的宽幅切割设备白皮书中说:“随着技术的不断发展,平板切割机在宽幅喷印市场形成了一个新的发展方向。”

Urmano reports that InfoTrends expects this trend to continue well into the future, largely due to the growing population of wide-format UV flatbed printers.“Today's board printing devices enable the user to continually feed boards to the flatbed cutter/router without waiting to queue up the next board.”

尔马诺指出:“由于宽幅UV平板喷印机数量的不断增长,赢船公司期望在未来能有更好的发展。目前的设备可以为平板切割机连续性地供给板材。”

Creative Apps

数码喷印技术的创新应用

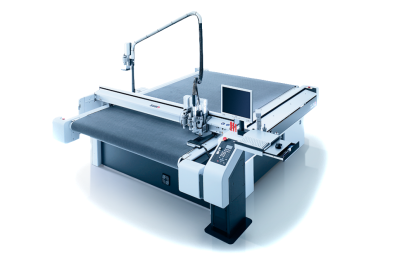

Beatrice Drury, director of marketing and communications, Zünd America Inc., Franklin, Wisconsin, says there are many different applications and unique products being made by their customers worldwide with Zünd flatbed cutters.

Zund美国公司市场总监碧翠丝·德鲁莉称,世界各地的消费者用Zund平板切割机生产出了许多不同用途的产品。

“Some projects include Honeycomb/corrugated display board applications, soft signage and textile applications,”she says.“The sky's truly the limit. There also appears to be a growing demand for greater productivity, through-put, customization, and just-in-time production.”

德鲁莉说:“蜂窝状的展板应用、软性标识和纺织应用,已经形成了一个新的应用领域,它们对高产量、物料通过量、定制化和即时生产这几个方面有更大的需求量。”

More Substrate Choices

材质选择的多样化

Steve Aranoff, MCT Digital's senior vice president of sales and marketing, with offices in Milwaukee, Wisconsin; and Pebble Beach, California; says there are more and more materials that can be effectively printed on, due to newer ink formulations and to increased use of coating and composite materials increasing the number of products that need to be finished. “These materials are ideal for digital cutters. For example both acrylics and fabric, which are handily cut by laser, are growth areas. Aluminum is also a critical material now for signs.”

MCT数码公司销售和市场营销部门高级副总裁史蒂夫·安诺夫称:“现在越来越多可以直接喷印的材料,都是用新型油墨配方、增强型涂层应用和复合型材质做成的,提高了精加工产品的数量。这些材料就非常适合数字切割。譬如,亚克力和纺织产品都能很好的被激光切割应用,它们也在不断地发展进步,同时,铝型材也是目前标识行业不可或缺的关键材料。”

Aranoff points out that many print service providers don't have the room or the budget to purchase multiple finishing solutions that are aimed at only one of these opportunities. “Our MCT VersaTech unit can handle virtually all of the finishing a print shop might need. When asked about what their next job will entail, most PSPs answer that they don't know," he says. "So, having the finishing equipment for virtually every option is a powerful marketing tool and allows them to gain more of their clients' business.”

安诺夫指出:“许多喷印服务商都没有机会和预算来购买多重精加工设备。我们的MCT操作平台几乎能处理所有喷印厂商需要精加工的项目。当被问及他们下一步的工作,大多数喷印服务商都不愿意回答。因此,拥有一个适应所有选择的精加工设备是一个有力的市场营销手段,并且能给他们带来更多的客户。”

Textile Trends

织物喷印的发展动向

Aranoff says that more PSPs are also making the decision to print big, both with 10-foot wide roll-to-roll capabilities and/or with 10-foot wide rigid capabilities.“Given the trends in materials, there are now sufficient current or future opportunities for that cutter to also do a better job with textiles if a system that has or can have a laser added is purchased.

安诺夫称:“多数喷印服务商也决定做出大型的10英尺卷对卷应用和10英尺硬性宽幅喷印系统。考虑到材料的发展趋势,无论是现在还是以后,如果织物切割机附带有激光功能,就可以做出更好的产品。”

Why? Because textile printing is becoming less and less rectangular, requiring more capability than can be had from just a driven wheel knife cutter. With a laser there is almost no cut pattern that cannot be cut/finished and the fabric gets a sealed edge that will not fray. While driven wheel capabilities can also handle fabric, they lack the ability to handle even uncomplicated shapes that have tight corners, such as some flags and even only tabs.”

为什么?因为织物喷印的矩形越来越少,与驱动轮刀切割机相比,要求有更高的性能。激光切割几乎可以处理所有图案,织物切割则会使得密封边缘不易磨损。驱动轮应用也可以处理织物,但是它们却处理不了有死角的简单图案,就像一些标识和标签之类的。

Aranoff adds that choosing to finish patterns that can be easily mechanically cut becomes an issue both on jobs a PSP can accomplish, and the driven wheel does not seal the edge.“Even for fabric going into frames, having a fraying edge makes the mounting process harder.”

安诺夫补充道:“选择精加工那些容易被机械切割的图案,已经成为一个重要议题,尤其在喷印服务商能完成的项目和驱动轮不密封的边缘这两个方面。如果织物边缘有磨损的话,将会使安装过程更加困难。”

Producing Perfect Results

志在完美成果的切割设备

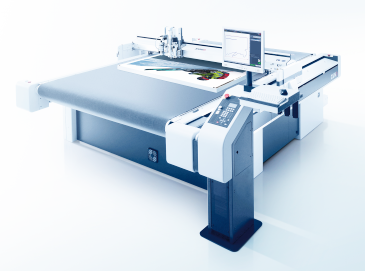

Greg Stewart is product marketing and strategy manager for Esko's Digital Finishing Business in Lake Geneva, Wisconsin. He points out that brand owners are struggling to design and produce signs and displays quickly and correctly, especially when personalized items are being produced geographically on a global scale.“This means that new display roll-outs must be produced perfectly. A good cutter will eliminate distortions between printed graphics and contour cut.

艾斯科数码精加工公司的产品营销和策略经理,格雷格·斯图尔特指出:“品牌所有者正努力快速准确地设计并生产标识和展板,尤其是当全球范围内都在制作个性化产品的时候。这意味着新展板的初次公开展示必须要完美。一个好切割机能消除喷印图案和轮廓切割过程中产生的失真。”

"It can also eliminate the need for endless trial-and-error test runs to adjust cutting depth to the substrate. It also requires control—control to make sure the workflow has created the correct graphics and coordinated cutting instructions for the table with the printing instructions for the digital press,” he says.

斯图尔特强调,好切割机能消除为校准切割介质深度,而进行的无休止的试验或错误测试。它还需要启动控制模式,确保数码按压喷印指令台的工作流创建了正确的图案和协调的切割指令。

He adds another trend is moving towards even faster delivery times.“It helps if you can spend as little time as possible to get your files print ready by automating all typical prepress jobs like pre-flighting, layouts, and creating cutting paths. Of course, the other challenge is that digital technology has made mundane two-dimensional signs less impactful on the store aisles. They are also commodity items. Printers tend to get into a price war for them, which obviously means less margins (and profit).”

斯图尔特补充道:“更快的传送速度是另一个发展方向。它可以让你在最短的时间内将产品喷印好,通过让所有特定的印前工作都自动操作,例如输出前预检,布局和设计切割路径。当然,数码技术削弱了普通二维标识的有效性。喷印机陷入了没有利润的价格争议中。”

Stewart points out that three-dimensional displays grab consumer attention.“Using three-dimensional tools such as ArtiosCAD structural design and Esko Studio for graphics, brand owners are able to create truly powerful displays that provide higher margins. Premium services allow you to charge more per printed piece.”

斯图尔特指出:“三维展板成功吸引了消费者的注意力。利用三维设备如雅图CAD包装结构设计软件和艾斯科包装图案设计软件,品牌所有者要做出真正有影响力的展板,就需要提供优质的服务,这样也提高了每块展板的利润点。”

Meeting a Wide Variety of Needs

适应多种需求的优质设备

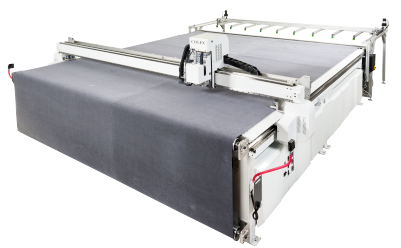

Maureen Damato, sales dealer account manager at Colex Finishing Inc., Elmwood Park, New Jersey, reports that the big trend she is seeing is the need for versatility, size and speed.“To meet these needs Colex introduced the Sharpcut SXC3232 super wide flatbed cutter 10.5" (3.2m) with cutting surface for the graphic and textile industries and automatic roll feeder and board loader option. This allows sign shop users to utilize the full width of the master rolls. As a result, there is less material waste allowing for a lower operating cost.”

美国克雷斯精加工公司的经销商客户经理,莫林·达马托称,她看到的新形势是市场对切割机通用性、尺寸和速度的需求。“为了满足这些需求,克雷斯推出10.5" (3.2m)锋利切割SXC3232超宽平板切割机——应用于图案和织物产业、并拥有自动补给料和平板装载功能。这样标识店铺就可以利用完整宽度的主卷,减少运营成本,及材料浪费。”

Digital Cutters vs. CNC Routers

数码切割机VS CNC数控设备

There are a number of major differences between CNC routers (X/Y/Z) and flatbed X/Y digital cutters. Aranoff says a full-on CNC router is not generally necessary in the digital printer's world.“Clearly vertical Z-axis control is necessary when routing complex shapes such as kitchen cabinets and door frames, but most digital print only requires an X/Y cut at a specific depth. Even then, by utilizing multiple layers in the design, a certain amount of Z-axis control can be accommodated, although not a full 3D pattern.”

CNC数控设备(X/Y/Z)和平板X/Y数码切割机有很多的不同点。安诺夫称:“一台CNC数控设备在数码喷印机时代是没有必要存在的。当然,垂直的Z轴控制在数控复杂形状的时候是很有必要的,例如橱柜和门框,但是大部分特定深度的数码喷印,只需要X/Y切割就可以完成。即使它不是一个完整的3D图案,特定数量的Z轴控制也能够适应多层结构的设计。”

“For typical printed materials, with relatively small depths, typically not over ½ inch, it is more important for a router to run at very high speed (60,000 rpm for MCT’s VersaTech) then at typical woodworking router speeds of 18,000 to 24,000 rpm. And while thicker materials may be more efficiently cut with high power at lower revolution speed, printed graphics need the revolution speed at lower power to create the cleanest and fastest cut.”

“对于特有的相对深度不超过1/2英寸的喷印材料,数控设备运行在高速下(MCT机床每分钟60000转)比在标准木工数控速度下(每分钟18000到24000转)更重要。偏厚材质用高功率切割时,在较低的运行速度下可能会更加有效,而喷印图案则需要在低功率下的运行速度来选择最新和最快的切割方式。”

Different Printing Formats

喷印格式的多样性

In addition, Aranoff explains that full on routers are typically run by operators who understand the routing process and normally input files in the CAD format.“On the other hand, printers and PSP are used to running in a Postscript environment with nested files coming directly from a printer RIP and having standard methodologies for cutting based upon the material, rather than the finishing pattern. We have seen that full-on routers used in a print environment make for a major training exercise in comparison to adding even a different flatbed cutter with good routing that may work somewhat differently than another brand of cutter, but yet still similarly.”

安诺夫还解释说:“数控设备主要是依靠了解数控程序并且能正常输入CAD格式文件的操作员运行的。另一方面,喷印机和供应商通常都是利用设备配套的软件,比对精准参数调整路径,确保画面精度。与高性能平板切割机相比,用于喷印领域的数控设备可以更好地保证产品的运作,提供高质量产品。”

Aranoff says that there are also major differences between routing and tangential cutting that make full routers less useful as a cutting system, except for occasional use.

安诺夫称,在数控和切向切割之间主要的不同点,就是数控在切割系统方面应用的更少,除了特殊场合使用之外。

“Overall, understanding print workflow and the PSP's knowledgebase make it hard for full-on routers to do the same kind of work that most PSPs require of a single system,”he says.“However, if a PSP is doing a majority of heavily 3D wooden signs compared to more traditional thinner printed materials, a full-on router might be the best solution.”

安诺夫说:“总的来说,了解喷印工作流和喷印服务商基础知识,对要求单一系统的多数喷印服务商来说,很难做出同一种类型的产品。然而,与传统的较薄喷印介质相比,喷印服务商在做大量重型木制3D标识时,数控设备可能会是最佳选择。”

Versatile Cutting Solutions

切割解决方案的通用性

Stewart says a full-on CNC router does offer more power for that type of function than a finishing table.“However, that is only helpful for very demanding substrates, and for only one step of a project. The best part of a flatbed digital cutter is that it is extremely versatile. It will work on just about any material—from light papers and foams to acrylics and aluminum composite materials—and will perform most functions that any sign and display shop would ever need. This includes not only milling and routing, but cutting, partial cutting, V-cutting, creasing, milling, polishing, engraving, among others.”

斯图尔特称:“CNC数控设备比精加工设备能提供更大的功率。然而,它只是对高性能介质和简单项目有益。平板数码切割机最大的优势就是它的通用性。它可以使用任何介质工作——从轻纸质泡沫到亚克力和铝型材复合物,并且它可以满足任何标识和展板店铺需要实现的功能。这不仅需要碾磨围字,也需要切割、部分切割、V型切割、压痕、碾磨、磨光、雕刻等等。”

He adds that from the smallest odd-shaped countertop display to the largest display piece, a flatbed finishing table allows users to tackle a wide range of applications.“Outsourcing all highly specialized finishing jobs is a waste of money. With the right cutting table you can do these jobs in-house without hurting your margins.”

斯图尔特补充道:“无论是最小的不规则的工作台面,还是最大的展板,平板精加工机器都能够让客户获得大范围的应用。高度专业化的业务外包精加工就是金钱浪费。有了合适的切割台面,你就可以不用花钱自己完成了。”

Advantages of Flatbed Cutters

平板切割机的主要优势

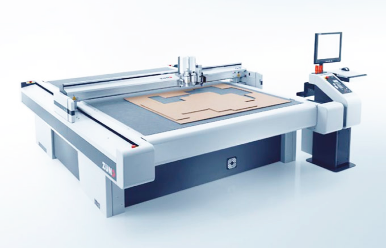

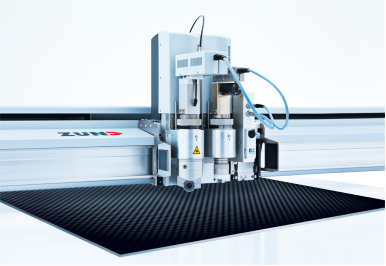

Drury says the some of the strengths/advantages particularly of a Zünd flatbed X/Y digital cutter over traditional CNC routers include versatility, digital cutting workflow and productivity.

德鲁莉称,Zund平板X/Y数码切割机与传统CNC数控设备相比,它的优点包含通用性、数码切割工作流和高生产率。

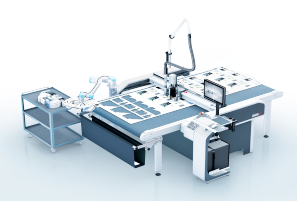

“Zünd offers a versatile range of tool, size, and automation option that to date, no CNC router can match. Our cutters are also used in so many different applications and types of production scenarios, a user-friendly end-to-end digital cutting workflow that's productive, automated, and adaptable is critical and one of the biggest advantages we offer. Maximizing productivity with a Zünd flatbed cutter includes tandem operation, touchless/QR-code based file retrieval, automatic tool setup/initialization and an automatic tool/router bit changer,”she adds.

德鲁莉称,“Zund公司提供工具、尺寸和自动化选择的通用性,这些是目前CNC数控设备无法匹敌的。我们的切割机同样适用于许多不同应用和生产方案,其中用户友好体验端对端数码切割工作流的关键就是高产量、自动化和适应性,这是我们提供的最大优势之一。”

Colex Sharpcut Flatbed Cutter

克雷斯平板切割机详述

Damato says a full-on CNC router will also typically have a larger router/spindle, allowing for larger cuts on thicker materials. A CNC router typically is not capable of cutting thinner material or roll media. The larger router also limits the linear speed of the machine because of its weight.

达马托称,数控设备通常会用一个较大的主轴来切割较厚的介质。CNC数控设备不能切割较薄介质或卷材介质。较大的数控设备也会因为重量而限制线性速度。

“For example, our Sharpcut is a knife cutter first and router second. With this mentality, Colex designed the Sharpcut to be as fast as other X/Y digital cutters and with the robustness of a CNC router. It bridges the gap by offering a router and knife system,”she says“The Triple Interchangeable Tool Head includes a Router and capability of installing two fixed knives. These fixed knives can be anything from a creasing wheel to a driven oscillating knife. The optional tools selection allows the sign shop user to customize their cutter for their specific workflow,”she explains.

达马托说:“例如,我们的锋利切割机先是切割机而后才是数控设备。带着这样的想法,克雷斯把锋利切割机设计成,速度和其他X/Y数码切割机一样、稳定性和CNC数控一样的设备。它缩小了数控设备和切割系统之间的差距。三重可交替刀头系列包含一个围字机和两个固定刀具,它们可以用来切割任何图案。根据客户不同的需求可以替换不同类型的刀具。”

Tool Head Options

刀头选择的重要性

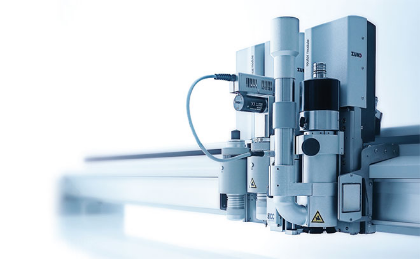

Aranoff says that tool head options are also a key to providing versatility and that the MCT VersaTech comes with both a heavy-duty tool position and two tangential drop in tool positions, meaning that three tools may be utilized at any time.“In the heavy duty position, there can be a 100-watt liquid cooled CO2 laser, a 3 HP 60,000 RPM router or a heavy duty driven wheel cutter that is self-sharpening. The two tangential tool positions are able to accommodate a straight knife, kiss cutting knife, electric oscillating knife, two sizes of creasing wheels, a variable v-notch cutter, and a space age pen system.”

安诺夫称:“刀头选择也是实现通用性的关键,MCT机床自带重型刀具和两切线刀具的位置,这意味着三个刀具可以同时工作。在重型刀具的位置上,一台100瓦液态冷却CO2激光,3HP每分钟60000转的RPM数控设备或重型驱动轮切割机是可以自动磨锐的。两切线刀具位置可以容纳一个笔直刀具、轻触切割刀具、电子振动刀具、两种尺寸的压痕轮、一个通用V型切口和一个空间系统。”

Different Strokes for Different Folks

找准定位的关键

Stewart adds an Esko Kongsberg table can cut a wide variety of materials.“It's Powerhead is used for heavy duty corrugated material, the Foam Head for foam materials and a separate Milling Unit (3KW) to mention a few.”

斯图尔特补充道:“一台艾斯科康士伯工作平面能够切割各种各样的介质。它的动力头用于重型波纹介质,泡沫头用于泡沫介质,一个分离的铣单元(3千瓦)举不胜举。”

Stewart explains that if you want to talk about specific materials,“for example, foam board requires high force cutting tools, although it's a pretty standard material for any cutting application. A rigid knife is sufficient.”

斯图尔特解释说:“若要讨论详细的介质,举个例子,泡沫板需要高强度切割工具,尽管它是切割应用的标准材质,一个坚硬的刀具就足够了。”

Cutting Paper and Plastic

纸质和塑料选择的困难性

He says that paper is relatively easy for cutting, using standard cutting and creasing tools.“Some of the high fiber boards can be more challenging and tooling can very depending upon the abrasiveness of the material. They could require more hardened or carbon-type tools to hold up under the strength of the materials.”

斯图尔特说:“用标准的切割和压痕工具切割纸质是很方便的。一些更具挑战性和工具性的高纤维板,很大程度上取决于材质的耐磨性。它们可能需要较硬的碳型刀具来支撑介质的重量。”

Stewart points out, as a general rule plastic is difficult because there are so many densities and ranges of type. “Tools, from a standard hardened knife to vibration knives or routing tools are all possibilities depending on the type, density and thickness of the plastic.”

斯图尔特指出:“一般来说,塑料的选择是很困难的,因为它有多种密度和类型。从标准坚硬的刀具到振动型刀具或围字刀具,这些很大程度上都是由塑料的类型、密度和厚度决定的。”

Aluminum and Other Materials

铝型材和其他材料的不同点

“A thinner grade of aluminum or aluminum composite materials can be cut on a standard digital finishing unit, if it has a 1-3 kilowatt router. Harder and thicker aluminum may require the use of heavier duty CNC routers,”explains Stewart.

斯图尔特解释说:“较薄的铝型材或铝型材复合材料可以用1-3千瓦围字标准数码精加工设备来切割。较硬或较厚的铝型材则要用重型CNC数控设备来切割。”

He adds that wood is processed with more routing tools than anything else.“Glass requires more abrasive tooling; for example, diamond tip tools with abrasive covers. These are used more for etching glass than truly cutting the material.”

斯图尔特补充道:“木质材料一般是用围字工具处理的。玻璃材质则是用耐磨的刀具处理,例如,粗糙表面的金刚石,主要用于蚀刻而非切割玻璃。”

“All in all, with a good finishing table and structural design program, one's creativity is the only limit. For starters, Esko offers its users access to a library of designs that can be customized for their own use,”Stewart says.

斯图尔特说:“总而言之,有了高性能设备和结构化设计程序之后,只需要发挥你的创造力了。对于初学者来说,艾斯科可以为你提供全方位的设备和服务来定制你的产品。”