Automated and computer numerical control (CNC) cutting systems are not new technologies, but recent improvements in versatility, speed and affordability have made them more attractive to signmakers and other fabricators. Today, many sign shops have integrated these systems into the finishing department of their production workflow.

自动化数控切割系统并不算是一项新技术,但是这种技术在多功能性、速度和可负担性方面的改进,使它们对标识制造商更具吸引力。今天,许多标牌商店已将这些系统整合到生产工作流程的后期部门。

Simply adding a system, however, is not enough on its own. Many signmakers equipped with one can still find themselves looking around their sign shop, spotting a particular material and wondering how to cut it. With that in mind, it is important to understand how best to use a CNC router to cut a broad array of sign industry substrates.

然而,仅仅增加一个系统本身是不够的,许多标识制造商仍然会寻找一种特殊材料来进行切割与制作,考虑到这一点,了解如何针对适合CNC切割设备的基板非常重要。

Substrate categories

基材类别

Signmaking materials tend to be categorized as either soft or rigid substrates. When using a CNC router, a knife blade is typically recommended for cutting a soft substrate, while a router bit is more practical for cutting a rigid one.

标识材料倾向于被分类为软质或硬质基材。在使用CNC切割机时,通常建议使用刀片来切割软质基材,使用刳刨工具则切割硬质基材。

Of course, these are very general recommendations for broad categories of materials. Signmakers also work with highly customized composite materials, in which case it is a good idea to speak to the manufacturer or a sales representative to get a specific recommendation with regard to cutting techniques.

当然,这些是针对大类材料的建议,一般标识制造商也会使用高度定制的复合材料,在这种情况下,与制造商或销售代表联系,以获得有关切割技术的具体建议才能更好的进行操作。

Pre-cutting steps

预切步骤

Before placing a material down for cutting, there are two important steps to consider. The first is the use of a ‘hold-down’ system to ensure the material does not shift while it is being cut. This is especially important when working with lighter materials, such as vinyl or cardstock, and when a substrate will have many cut-outs, leaving only a thin ‘skeleton’ of material behind.

在放置切割材料之前,需要考虑两个重要步骤,首先是使用压制系统来确保材料在切割时不会移位。当使用较轻的材料(如乙烯基材料或卡片纸)时,基材会有多个切口,仅留下一层薄的材料,这一点尤其重要。

This step usually involves attaching a vacuum system to the cutting table to create suction on it. A phenolic work surface with air channels can ensure an even distribution and flow of this suction throughout the table.

这一步通常包括将真空系统连接到切割台上,以在其上产生吸力,带有空气通道的酚醛工作台可以确保该吸力在整个工作台内均匀分布的流动。

The second step to consider is incorporating a ‘sacrificial’ material, also known as ‘spoilboard.’ This will be needed underneath any substrate the signmaker plans to cut entirely through, so the cutting tool has somewhere to go without hitting the work table. Such a collision has the potential to damage the tool.

第二步要考虑的是采用一种保护材料,比如刨花板,将它放在切割的基材下面,保证切割工具在切割过程中不撞击工作台,碰撞有可能会损坏工具。

Generally, two kinds of sacrificial materials are recommended. The first, ideal for knife cutting applications, is heavy felt. Felt is very porous, so it allows for plenty of air flow and vacuum suction for hold-down purposes. While it needs to be heavy enough to prevent the knife from piercing all the way through, it also needs to be soft enough not to dull the blade’s sharpness over time.

这种保护材料一般推荐两种。第一种是毛毡,毛毡非常多孔,刀具切割应用的理想选择是产生沉重感觉,而毛毡允许充足的空气流量和真空吸力来压紧。此外,它有足够的重量防止刀片一直穿透,同时也足够柔软,应对刀片的锋利程度。

The second option, for routing,is low-density fibreboard (LDF). Compared to medium-density fibreboard (MDF) that is commonly used in the sign industry, LDF does not incorporate the same type of sealant and its lower density allows for greater air flow.

第二种选择是低密度纤维板。与标识行业常用的中密度纤维板相比,低密度纤维板不包含相同类型的密封胶,其较低的密度允许更大的空气流动。

Some signmakers insist on using MDF as their sacrificial material, but in those cases, it is imperative to table-mill both sides of the material first, to remove all of the sealant. Otherwise, they would not achieve sufficient material hold-down.

一些标识制造商坚持使用中密度纤维板作为其保护材料,如果要用中密度纤维板,必须首先对材料的两面进行研磨,以去除所有的密封剂,否则,不会达到足够的效果。

Knife cutting

切割刀

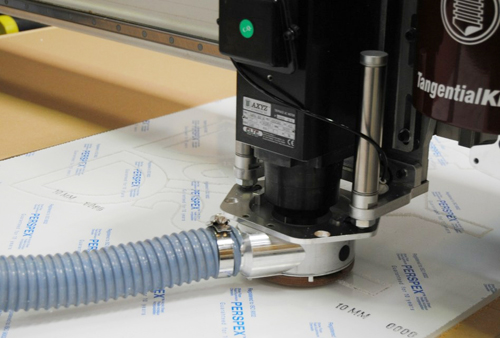

A CNC router’s knife cutter is ideal for use with thin or soft substrates because it involves none of the material removal inherent with routing. Thin cuts are especially helpful for highly detailed projects or when a large number of prints must be cut from the same sheet. Using CNC software, the router operator can ‘nest’ a large number of parts or cut-outs very closely together.

数控切割机的刀非常适用于切割薄或软的基材,细切对于高度详细的项目或大量的裁切特别有用。使用CNC软件,操作员可以将大量零件或切口嵌套在一起。

One of the main advantages of an automated cutting system is the ease of switching between various knife attachments. The most common types include kiss cut, drag and oscillating knives and there are a few other options for very specific applications.

自动切割系统的主要优点之一是易于在各种刀具附件之间进行切换,最常见的类型包括吻切、阻力刀和摆动刀,还有一些其他选项适用于特定的应用工具。

If a sign shop is creating vinyl cut-outs, decals or other products where the operator only needs to cut through one layer of material, then the kiss cut blade is the ideal choice. It is spring-loaded and automatically adjusts to the material being cut, so there is never a risk of cutting through the backing layer.

如果一家标识商店生产乙烯切割件、贴花或其他产品,而操作者只需切割一层材料,那么吻切刀片是最佳的选择,它由弹簧加载而成,可以自动调节被切割的材料,不会产生切割背衬层的风险。

If instead the CNC table operator is cutting a thin material but needs to cut all the way through, then a drag knife is a better option, as it can quickly pass through all layers.

相反,如果CNC工作台正在切割薄的材料,如果需要一直切割,拖刀是最好的选择,它可以快速穿过所有的层。

For a shop that deals in large volumes of thicker soft substrates, such as foam and rubber, oscillating knives are the best bet. Most are available in lengths of 10 to 100 mm (0.4 to 4 in.), depending on the shop’s needs. Variations include round-tipped oscillating knives designed to cut cardboard, rubber and softer materials, along with flat-tipped knives designed to cut leather and other fibrous materials.

对于经营大量较厚软质基材(如泡沫和橡胶)的制造商而言,摆动刀是最佳选择。根据商店的需求,大多数这类基材的长度为10至100毫米(0.4至4英寸),一般由用于切割纸板、橡胶和较软材料的圆头摆动刀,以及用于切割皮革和其他纤维材料的平头刀来操作。

Thicker materials create more drag when being cut, due to increased friction. Foam and rubber also naturally cause high friction, even when they are thin. The oscillation of the knife can help overcome this friction, resulting in a smoother cut and reducing the chance of the material being bunched or riped.

由于摩擦力的增加,较厚的材料在切割时会产生非常大的阻力,即使像泡沫和橡胶很薄的材料自然也会造成摩擦力,而刀的摆动可以帮助减小这种摩擦,促使平滑的切割,并减少材料成团或撕裂的可能性。

Two other specialized knives can come in handy for sign shops. The V-groove knife, also known as a 45-degree knife, is used to cut grooves at a 45-degree angle in framing and display materials. This allows operators to then fold the two edges together to form a clean 90-degree angle to quickly create frames or displays for signs.

V型槽刀也称为45度刀,适用于在框架和材料中,以45度角切割槽,这样操作员可以将两个边缘折叠在一起,形成一个干净的90度角,以快速创建框架标识。

Finally, the creasing wheel is handy for signmakers who need to create point-of-purchase (POP) displays and other structural projects using cardstock, foamboard or other cardboard-based materials. The wheel creates sufficient pressure for indentation and folding, without puncturing the material.

压痕轮适用于卡片纸、泡沫板或其他纸板材料所创建的POP显示器和其他结构项目的标识,该轮为压痕和折叠创造足够压力的同时,也不会刺穿材料。

Routers

切割系统

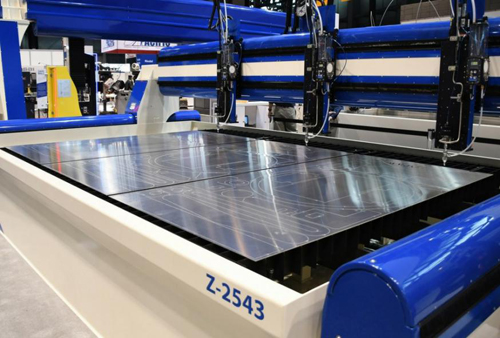

If a sign shop specializes in thicker or stiffer substrates, then a CNC router is most likely the best machine to use for cutting. Depending on its configuration, a router will let operators cut a wide range of materials, from wood to aluminum, at various thicknesses and speeds.

如果一家标识商店专门生产较厚或较硬的基材,那么CNC切割设备很可能是最好的切割机器,根据其配置,切割系统可让操作员以各种厚度和速度切割各种材料,从木材到铝材。

In addition to choosing the right router for a sign shop’s needs, it is also important to use the appropriate router bits, based on the type and thickness of the material and the desired edge quality. It is extremely worthwhile to spend extra time and money to ensure proper bit selection from the beginning, to get the most out of the system.

除了为标识制造商的需求选择正确的切割系统之外,根据材料的类型和厚度,以及所需的边缘质量,使用合适的位也很重要,花费额外的时间和资金来确保从一开始就选择了合适的位,以充分利用系统是非常有价值的。

Each material has its own ‘sweet spot’ with regard to optimal cutting parameters, so there is no single right answer in terms of feed rates and routing speeds, although there are some general rules that should be kept in mind. Below are some best practices for selecting routing bits and tools for some of the most common sign materials. Ultimately, however, it is essential to reference the router and bit manufacturers’ guidelines to ensure the best cut quality and the maximum longevity for the tools. Feed rate calculators, for example, are a fantastic resource and can often be found on both CNC machine manufacturers’ and tool suppliers’ websites. A combination of following manufacturer guidelines and some in-house testing will yield the best results, with the lowest chance of damaging tools.

每种材料在最佳切割参数方面都有自己的定位点,所以,在进给率和布线速度方面没有单一的正确答案,但应该牢记一些通用规则,比如参考切割设备和钻头制造商的指导方针,以确保工具的最佳切割质量和最长使用寿命。例如,通常可以在数控机床制造商和刀具供应商的网站上找到指导方针和一些内部测试组合产生的最佳结果,将损坏工具的可能性降到最低。

Wood

木质材料

There are hundreds of tooling options for cutting wood. The choice will depend on the species of tree and whether it is classified as hard or soft. It will also depend on the level of finish required.

切割木材的工具选项有数百种,选择取决于树的种类以及是否分类为硬或软,也将取决于所需的完成程度。

When working with wood that is quite porous, such as oak, routing can result in tearout, i.e. splintering of the edges. In such cases, several slower, shallower cuts are recommended.

当使用橡木等多孔的木材时,布线会导致撕裂,即边缘碎裂,在这种情况下,建议进行几次较慢、较浅的切割。

MDF

中密度纤维板

MDF is a very popular structural material in a wide variety of sign projects, but it is also very abrasive to cut, so it can pose a threat to tool longevity. This is because highly abrasive materials can generate a lot of heat during cutting, which can lead to tool degradation and spindle damage, not to mention poor cut quality.

中密度纤维板是各种标识项目中非常受欢迎的结构材料,但是,对这种材料的切割也非常麻烦。这种高度磨蚀的材料会在切割过程中产生大量热量,从而导致刀具退化和主轴损坏,对工具的寿命构成威胁,降低切割质量。

To help reduce heat around the routing tool, it is important to choose a bit that will create more chips, not dust. Carbide-coated compression tools are recommended above weaker higher-speed steel (HSS) tools. And if a sign shop is cutting MDF very frequently, it will be worthwhile to use polycrystalline diamond (PCD) bits which, over time, will yield a strong return on investment (ROI).

为了散发切割工具周围的热量,选择一个可以创造更多芯片而不是灰尘的位非常重要。在较弱的高速钢工具上,应使用硬质合金涂层的压缩工具。如果一家标识制造商非常频繁地切割中密度纤维板,那么使用多晶金刚石钻头是非常有必要的,这些钻头会在长期内,产生强大的投资回报。

Acrylic

亚克力

When cutting small or thin pieces of acrylic, it may be a good idea to enhance the CNC router’s hold-down system. A vacuum system is important, but adding some double-sided tape might also help.

在切割丙烯酸树脂的小片或薄片时,增强CNC切割压制系统可能是一个好主意,真空系统很重要,另外还要添加一些双面胶带。

It is certainly advantageous to use acrylic-specific bits. Chip removal is much more important when cutting acrylic than when cutting wood or similar materials. This is because plastic chips can melt under the heat of routing and then re-attach themselves to the main piece, so the operator needs to make sure they are cleanly removed from the cutting area.

在切割丙烯酸比切割木材或类似材料时,使用丙烯酸专用钻头会更好,这是因为塑料碎片会在热量下融化,然后重新粘贴到主件上,因此,操作员需要确保将它们在切割区域清除干净。

How acrylic is cut also depends on the desired edge quality. If a crystal-clear edge is needed, than routing can prove difficult. PCD polishing tools are available that can create a nearly optically clear edge for acrylic, avoiding the need for flame polishing, but for shops that are constantly cutting acrylic and need a clear edge, laser cutting may be the best way to go.

丙烯酸如何切割取决于所需的边缘质量,如果边缘清晰,则难以布线,PCD抛光工具可为亚克力创造近乎光学清晰的边缘,从而避免火焰抛光,但是,对于不断切割丙烯酸并需要清晰边缘的制造商来说,激光切割可能是最佳途径。

Aluminum composite

铝复合材料

Aluminum composite panels are very popular among signmakers because they are light, durable and easy to work with. While they combine layers of different materials, the aluminum itself is sufficiently tough that solid carbide tools are essential for cutting it. Coated tools will hold up better, too, ensuring greater longevity. That said, some tools designed for cutting plastics will work well on aluminum composites.

铝复合板在标识制造商中非常受欢迎,因为它们轻便耐用,且易于使用,虽然它们结合了不同材料的层,但铝本身足够坚硬,以至于整体硬质合金刀具对于切割它来说是不是问题。涂层工具越好,材料的使用寿命越长,也就是说,一些设计用于切割塑料的工具可以很好地用于铝合金复合材料。

Tools that are 6.4 mm (0.25 in.) or smaller in diameter and have fewer than four flutes are recommended. Aluminum creates large chips when it is routed and a tool with too many flutes can cause jams and even break the cutter.

所以,我们建议使用直径为6.4毫米(0.25英寸)或更小且刀片少于四个的刀具,要不然在铝制成大型切屑时,会因为工具的排屑槽过多,可能造成卡纸甚至切刀的损坏。

Another issue is how heated aluminum tends to weld itself onto the tool. Once a tool is gummed up like this, it is useless. So, it is all the more important to clear chips with a vacuum, mister and/or blaster. Making a large number shallow passes, rather than fewer deep passes, will also help with chip extraction. Finally, a slow feed rate can start to cause rubbing, which then heats up the tool and can dramatically reduce its longevity, so it is important for the operator not to ‘baby’ the cut.

另一个要注意的问题是加热铝时,如何将其自身焊接到工具上,一旦这样的工具被粘上去,它就没用了,所以,清理芯片非常重要,而制作大量的浅通道,而不是较少的深通道,也将有助于芯片的提取。

Foamboard

发泡板

High-density urethane (HDU) is often known in the sign industry as foamboard. And indeed, it routs similarly to a foam type of material, so heavier cuts are better.

高密度聚氨酯在标识行业中通常称为发泡板,事实上,它类似于泡沫类材料,所以需要大的切口。

This means the tool needs more material to grab, so it is important to ensure cuts are at least half-diameter passes. Again, constant chip flow is important.

这意味着该工具需要充足的材料才能确保切割至少有半径的到位,同样,恒定的芯片也很重要。

For highly detailed three-dimensional (3-D) routing, an endmill should be used for the rough passes and then a ballnose bit for the finishing passes. HDU is a great material for 3-D routing and relief production and it can easily be coated and painted afterwards.

发泡板是一种用于三维制作的材料,可以容易地进行涂层和涂漆。对于高度详细的三维路径,应该使用立铣刀进行粗铣,然后使用球头进行精铣。

These are just some general tips for commonly used sign materials. Identifying the type of material to be cut, the best-suited machine to cut it and the specific tool for the job are all important steps in ensuring the best quality for the application. By working with CNC machine manufacturers and dealers, tooling suppliers and material manufacturers, signmakers can meet their clients’ needs with the best approach for any application.

以上是常用标识材料的一些常规提示。识别要切割材料的类型,找到切割它最适合的设备,以及用于该工作特定工具的最佳质量都是切割过程的重要步骤。通过与数控机床制造商和经销商,模具供应商和材料制造商合作,标识制造商可以针对任何应用以最佳方法满足客户的需求。