As effective as “word of mouth” advertising is, having a tenant move in with a new sign installed next to your space is perhaps even more effective. After a new tenant, PROSTAFF, moved in and seeing their recently installed sign, Kemnitz Orthodontics decided to update its sign. The Kemnitz Orthodontics sign is about 10 years old, and while it had served its purpose well, it had lost most of its luster. It was time to either get a new sign or update the existing one.

就像“口口相传”的广告一样,邻居新租户的崭新标识可能更会促使你去更新自己的标识。Kemnitz Orthodontics就是在看到他们隔壁新租户PROSTAFF安装的标识后,决定对自己的标识进行更新。Kemnitz Orthodontics的标识大约有10年的历史,虽然它已经很好地发挥了它的作用,但它的照明功能也越来越微弱。是时候购买一个新标识或对现有标识进行更新了。

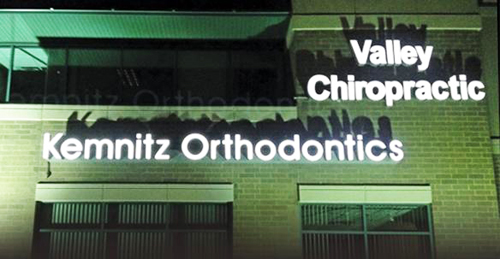

The Kemnitz Orthodontics sign, positioned on the wall between the PROSTAFF and Valley Chiropractic signs, is illuminated with white neon tubes while the other two signs are illuminated with white LEDs.

Kemnitz Orthodontics的标识位于PROSTAFF和Valley Chiropractic标识之间的墙壁上,他的标识使用的是白色霓虹灯光源进行照明,而其他两个标识则是使用白色LED光源进行照明。

The electrical was disconnected and the sign was removed on a Thursday morning. The sign, with 18" tall letters, actually consisted of three raceways attached to one another, but it was easier to remove it all in one piece. The intent was to re-install the sign the next day but in the event something unexpected happened, the shop would have the weekend to complete the project and the customer was comfortable with having the sign re-installed the following Monday if the need arose. Obviously, the goal was to eliminate as much downtime as possible.

一个周四的清晨,在断开电源后,标识被拆卸下来,这是一个18英寸高的标识,由三个相互连接的线槽组成,但是可以将它们一次性进行拆除。原本的计划是在第二天进行标识的重新安装,但是总有意外发生。商店不得不将标识带回店里并在周末进行标识的改造工作,而客户也同意在下周一进行标识的重新安装。因此,现在的任务就是尽快将标识改造的任务完成。

Dismantling the sign began as soon as it was returned to the shop. After removing the screws that secured the trim cap and faces to the letter returns, the screws were placed on a “homemade” holder, a small corrugated box, and all the faces were placed in one location. It’s amazing what can get lost when there’s no plan.

一旦将标识送回商店,拆除标识的工作就会立刻开始。在取下固定装饰盖和发光字外壳的螺钉后,将螺钉将被放在一个自制小瓦楞纸箱的支架上,并且所有螺钉将面朝同一个方向。提前安排好的工作计划,将保证我们的工作能够有条不紊地进行下去。

Next, the neon tubes, wiring, standoffs, and transformers were removed and the standoff bases were ground flush with the bottom of the letter cabinet. The neon lighting for this sign required three 7530 transformers, each capable of approximately 216 watts of power.

接下来,我们将对霓虹灯灯管、电线、压铆螺母柱和变压器进行拆除,压铆螺母柱通常位于灯箱的底部。这个标识的霓虹灯系统需要三个7530变压器,每个变压器能够提供大约216瓦的功率。

Once the faces and the “innards” were removed and the inside of the letters was revealed, it was almost like a miniature “farm” had been placed inside each letter. It’s anybody’s guess what was “growing” inside but as the photos show, it wasn’t very pretty.

一旦标识的外壳和内部构造被拆分并清楚地呈现在人们的面前时,每个标识字母内部就像一个微缩的“农场”,谁也猜不到过去里面发生了些什么,但根据照片来看,情况不是很好。

The letters and raceway were taken outside and power-washed as well as scrubbed with soap and a brush. Once the washing was completed, the letters and raceway were brought back inside so that all moisture could be removed from inside the cabinets. After wiping the interior of each cabinet, a hairdryer was used to ensure all moisture had been removed.

发光字和线槽被带到室外并使用肥皂和刷子对其进行清洗。在清洁干净之后,发光字和线槽又被搬回室内进行内部干燥。在将灯箱表面的水分进行擦拭后,我们使用吹风机来确保剩余的水分均被干燥透彻。

Once the drying process was completed, it was time to begin the initial placement of the LED modules and wiring. Nothing was secured to the letter backs until everyone was sure that the placement was optimal. After all the modules and wiring were placed, power was applied and each letter and checked to ensure even lighting throughout the letter. Confident that placement was correct, the adhesive on the back of the LED module was exposed and the module was secured to the letter back. In addition to the module adhesive, a bead of silicone caulk was laid down beside each module, as well as any wiring that wasn’t flush with the letter backs, to ensure all were secure. For this particular letter stroke, a single row of LEDs was sufficient to produce the desired, and customer-expected effect.

一旦干燥过程完成,就可以将LED模组和电线安装回标识内部了。找到模组和电线最佳的安装位置并将其安装好后,我们就可以通过接通电源来检查每个发光字内部的照明是否均匀。在确认好模组和电线安装正确之后,就可以将LED模组背面涂上粘合剂,并将其固定在发光字的背面。在将模组粘合好之后,在每个模组周边填上一层硅树脂填缝剂,以保证电线也是整齐地安装在发光字背部的表面。对于这种特殊的标识构造,单排LED足以提供客户期望的效果。

The white LEDs that were used for this project came from JT LEDs. There are three LED modules for every 12" of wiring and each LED module is 1 3/4" long, Each LED module puts out 0.4 watts, modules are spaced 2 3/4" apart, and one 60 watt power supply can power 130 modules. If you aren’t sure about proper placement for your LEDs, try consulting your LEDs manufacturer or use a program such as Sign Wizard.

用于该项目的白光LED由JT LED公司提供。每12英寸长度的电线上安装了三个LED模组,每个LED模组长1又3/4英寸。每块LED模组输出功率为0.4瓦,相邻模组间隔2又3/4英寸,一个60瓦电源可以为130个模组供电。如果你不能确定LED的正确安装位置,可以向你的LED制造商进行咨询或使用Sign Wizard等程序进行查询。

Once all the LEDs, wiring, and single power supply had been placed and sealed and before the faces were installed, another check of the lighting was done to ensure everything worked.

一旦所有的LED、电线和单个电源都已安装完成并密封后,在安装外壳之前,你必须再次对照明情况进行检查以确保一切能够正常运行。

As previously mentioned, the sign was removed on a Thursday morning, beginning at about 9 a.m., and work stopped at about 4:30 p.m. that afternoon. All work had been completed with the exception of re-installing the faces. The next morning at about 8:30, one final check was made to ensure all the LEDs and wiring were secure and lighting correctly. The faces were re-installed and by 10:15 a.m.; the sign was re-installed on the building as if it had never been removed.

如前文所提到的,这个标识在上周四早上9点开始进行拆卸,并于下午4:30左右停工。除了重新安装外壳的工作之外,其他工作均已完成。第二天早上8:30分左右,我们进行了最后一次检查,确保所有的LED模组和接线都是安全的并且能够得到正确的照明。这些发光字在上午10:15被重新安装,最终改装后的新标识被安装在原有的建筑物上,好像它从未被移除过一样。

As can be seen in the photo comparison, there is a considerable amount of difference in lighting. The sign looks new once again.

从照片比较中可以看出,新旧标识的照明效果存在相当大的差异,这个标识焕然一新。

Customers sometimes ask if their sign can be retrofitted without removing it. Winter conditions warrant this work be done in the shop. Under summer conditions, it is possible to field-retrofit a sign, but in the end, it will, almost every time, be quicker to take it down and do it in the shop.

客户有时会询问他们的标识是否可以在不拆除的情况下进行改装。我的回答是,冬季的工作环境要求这项工作必须在商店内完成;而在夏季的工作环境下,则可以对标识进行现场改造。但实际上,几乎每次都是将标识拆卸下来后,在室内完成标识的改造。

The three transformers for the original neon sign consume 216 watts per transformer for a total of 648 watts. Presuming the sign will be lighted for 12 hours per day, 7,776 watts will be consumed. Converting to kWh, there are 7.8 kWh and based on an electrical cost of $.13 per kWH, it will cost $1.014 per day which, based on 365 days per year, will have an annual cost of $370.11.

原来的霓虹灯标识的三个变压器每个变压器消耗216瓦,总功率为648瓦。假设标识每天点亮12小时,将消耗7,776瓦。转换为kWh,有7.8 kWh的消耗量,按照每千瓦时0.13美元的电费来进行计算,每天将花费1.014美元,再按每年365天来计算,每年的成本为370.11美元。

The one power supply for the sign retrofitted with LEDs consumes 60 watts. Presuming the sign will be lighted for 12 hours per day, 720 watts will be consumed. Converting to kWh, there are .72 kWh and based on an electrical cost of $.13 per kWh, it will cost $0.094 per day. Based on 365 days per year, the sign will have an annual cost of $34.31.

用LED模组改装的标识的一个电源消耗约60瓦。同样假设标识每天点亮12个小时,将消耗720瓦特。转换为kWh,即为0.72 kWh,按照每千瓦时0.13美元的电费来计算,每天将花费0.094美元,再按每年365天来计算,该标识每年的成本为34.31美元。

One final observation. Obviously, the cost of electricity is not the same in all parts of the country and the numbers will always be different unless the cost per kilowatt hour is the same. Just as obvious, cost savings will differ with each sign and the color of LEDs. The cost savings cited were based on 13 cents per kilowatt hour for a specific sign with a specific amount of white LEDs and one power supply versus a specific sign with a specific, linear amount of glass tubes and three specific transformers that produced a specific color.

最后一提。显然,全国各地的电力成本并不相同,除非每千瓦时的成本相同,否则数字总是不同的。同理,每个标识和LED的颜色选择都会对成本有一定的影响。我上面所提到的成本计算方法是以每千瓦时13美分来估算的,样本标识则分别是具有特定数量的白色LED和一个电源的发光字以及拥有特定数量的线型霓虹灯管和三种产生特定颜色变压器的发光字。

I don’t always recommend LEDs over neon because I truly believe there’s a time and place for both. LEDs have a tendency to degrade over time, but how much time and how much degradation will depend a lot on the quality of the LED, color, installation, and whether or not the correct power is being applied to the LEDs. The same thought pattern can be applied to neon as well. Additionally, any neon color, other than the reds or oranges, will dim in cold-weather states, such as Minnesota, and the colder the temperature, the dimmer it becomes.

相比于霓虹灯,LED光源并不总是我的首推,时间和应用地点都会对决定使用哪种光源产生影响。LED光源会随着时间的流逝而逐渐产生耗损,但是这个保质时间和退化程度将在很大程度上取决于LED的质量、颜色、安装方式以及应用的电源功率是否合适。同样的思维模式也可以应用于霓虹灯的使用中。此外,除了红色或橙色之外,任何霓虹灯的光源颜色都会在寒冷天气的状况下变暗,例如在明尼苏达州,温度越低,霓虹灯的亮度就越暗。