The printing of fabrics has seen a revolution in recent years with the advent of digital technology, which has saved significant time, money and labour compared to the days of screenprinting. While the earliest digital fabric printers could process 8.2 m (9 yd) in a day, making them suitable only for prototyping purposes, today’s large-format dye sublimation presses can meet growing customer demand for the on-demand production of customized soft signage applications, ranging from flags and banners to lightboxes.

近年来,随着数码技术的出现,织物的印刷经历了一场革命。与丝网印刷相比,数码印刷节省了大量的时间、金钱和劳动力。虽然最早的数码织物印刷机可以在一天内处理8.2米(9 码)长的织物,它们只适合于原型印刷,而今天的宽幅染料升华印刷机可以满足日益增长的客户需求,即定制的软标识应用,从旗帜和横幅到灯箱。

Construction and finishing

结构和表面加工处理

Circular and woven knits are mostly intended for apparel, as well as home furnishings.

圆形和编织针织物主要用于服装和家居用品。

There are several types of fabric constructions. Circular and woven knits are mostly intended for apparel and home furnishings. While some woven fabrics are ideal for soft signage applications, the industry relies primarily on warp knits, as they offer the greatest dimensional stability.

织物结构有几种类型。圆形和编织针织物主要用于服装和家居用品。虽然有些编织织物是软标识应用的理想材料,但该行业主要依靠经线编织,因为它们提供了最大的尺寸稳定性。

A warp knit uses a locking stitch to provide this stability, which helps ensure a single rip in the fabric will not easily extend all the way across it. Further, a dimensionally stable fabric will not sway or torque too much after it is installed in a frame or lightbox, so the graphics should remain easily readable.

经线编织使用锁针来提供这种稳定性,这有助于确保织物上的单一裂缝不会轻易地扩大和延伸。此外,尺寸稳定的织物在被安装到框架或灯箱中之后,不会产生太大的摇摆或扭力,因此图形应该保持易于观看或阅读。

Similarly, larger air holes in the fabric are preferable, as they allow wind to pass through a banner. This in addition to the lighter weight of fabric compared to polyvinyl chloride (PVC) means soft signage is a safer option, less likely to fall on anyone.

同样,在织物上有更大的通风孔更好,因为它们可以让风通过横幅。此外,与聚氯乙烯(PVC)材料相比,织物的重量更轻,这意味着软标识是一种更安全的选择,不太可能掉落下来打到人。

Beyond the initial construction of a fabric, finishing also plays an important role. With soft signage applications in mind, some of the most popular after-knitting finishes for fabrics include flame retardant (FR) and durable water repel (DWR) treatments.

除了织物的初始构造,加工也起着重要的作用。考虑到软标识的应用,一些最流行的织物后编织物处理包括阻燃(FR)处理和持久的防水(DWR)处理。

Not all finishes are applied in the same way, however, and so there are varying levels of effectiveness. It is worthwhile to check how a fabric’s finish has been implemented and how long it will last.

然而,并不是所有的成品都以相同的方式处理,因此有不同程度的效果。有必要检查一下织物的加工情况,以及加工过程将持续多长时间。

The most durable FR treatments, for example, are accomplished by staining the yarns before they are even woven. The resulting fabrics are more expensive than alternatives, but will provide a lifetime of protection against burning. Also, they can be washed without reducing their effectiveness, which is not the case with fabrics carrying lower levels of FR protection.

例如,最持久的FR处理是在纺纱前就对纱线进行染色。这种织物比其他的织物更贵,但可以提供终身的防火保护。此外,它们可以在进行清洗时也不会降低其有效性,但织物的FR保护水平较低的情况就不是这样了。

Most professionals look for the American Society for Testing and Materials’ (ASTM’s) E84 standard for FR.

大多数专业人士都会参考美国材料与测试协会(ASTM s)的E84 FR标准。

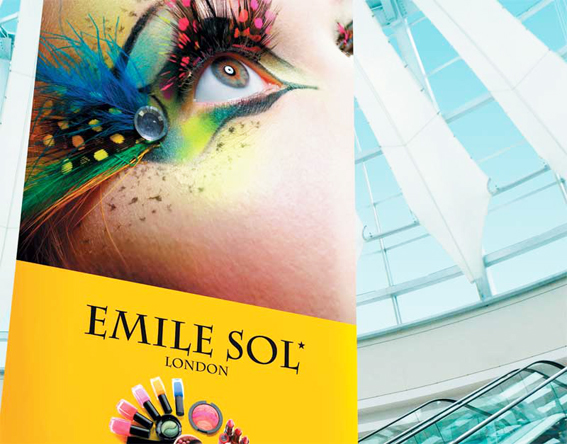

Customized soft signage applications range from flags and banners to lightboxes.

定制的软标识应用范围从旗帜和横幅到灯箱。

Performance testing

性能测试

Fabrics are tested for weight, shrinkage, washability, strength, torquing, snagging, air permeability, crock (i.e. how well dyes or inks remain on the material), moisture resistance, colour migration and elasticity. When selecting fabrics, signmakers should be cognizant of which of these attributes are most relevant to their applications.

织物的重量、收缩性、可洗性、强度、扭力、起毛、透气性、砂体(即染料或油墨在材料上的维持程度)、防潮性、色彩保持度和弹性都要经过测试。在选择面料时,标识师应该知道哪些属性与他们的应用最相关。

Elasticity, for example, has become particularly important due to the industry’s increased use of silicone edge graphic (SEG) frames, which make printed graphics easier to install and change out as desired. Only a stretchable fabric can be fit property into such a frame, with the right level of tension, and not exhibit unwanted wavy lines across its graphics. Equal stretch is desirable in all directions.

例如,由于业界越来越多地使用硅胶边缘图形(SEG)框架,弹性变得尤为重要,这使得印刷图形更容易安装和根据需要更换。只有可拉伸的织物才能在这样的框架中具有合适的张力,并且不会在图形中出现不必要的波浪线褶皱。在各个方向上都需要能同样地伸展。

While sophisticated machines can allow manufacturers to fabricate very high-quality fabrics for the sign industry, it is important to keep in mind no roll is 100 per cent perfect. Further, not all fabrics behave the same way in the printing process. Whenever a sign shop switches materials, it will also need to switch its printing profiles for the intended application. Fabric manufacturers might even buy their own yarns from different sources over time, which can affect the consistency of their products.

虽然精密的机器可以让制造商为标识行业制造非常高质量的面料,但重要的是要记住,没有一卷是百分百完美的。此外,并不是所有的织物在印刷过程中都有相同的呈现效果。每当标识商店更换织物时,它还需要为预期的应用更换其印刷材料。随着时间的推移,织物制造商甚至可能从不同的来源购买自己的纱线,这可能会影响他们产品的一致性。

Preventing problems

预防问题

Larger air holes in fabric will allow wind to pass through digitally printed banners.

织物上较大的通风孔可以让风通过数码印刷横幅。

Common issues that can negatively affect dye sublimation include uneven tensioning on the fabric rolls, collapsed or crushed cores (i.e. tubes) of those rolls, wrinkles, dirt, defects and shrinkage beyond about five per cent.

可能会对染料的升华产生负面影响的常见问题包括织物卷上的不均匀拉伸、破损或压皱芯(即卷管)、褶皱、污垢、缺陷和超过5%的不均匀收缩。

The effectiveness of dye sublimation also depends on proper settings for each fabric, which may best be determined through testing. It is worthwhile for signmakers to keep a journal of this testing process, documenting how well each setting works for each fabric, noting the lot and roll numbers.

染料升华的效果还取决于每一种织物的适当设置,这可能最好通过测试来确定。对于标识制作师来说,记录下这个测试过程是有必要的,记录每种设置对每种织物起到的效果,记录批号和卷号。

There are many heat presses available for dye sublimation, but a high-quality machine is worth the heftier investment, as it should last forever with routine maintenance, can be passed down to the next generation and will retain much of its resale value. All that needs to be changed out is the belt.

有许多热压机可用于染料的升华,但高质量的机器值得更大的投资,因为它通过良好的日常维护应该能永远持续使用,可以传递给下一代人使用,并将保留其大部分转售价值。所有需要改变的就是热压带。

The key settings for calendering with a heat press are time, temperature and pressure. The average sign shop uses about six to eight different fabrics for popular soft signage applications and the heat press will need to be calibrated with the ideal settings, as mentioned, for each material. A heavier fabric, for example, will need more pressure applied during calendering, while underdeveloped shades call for greater heat.

热压压延的关键设置是时间、温度和压力。一般的标识店使用大约6到8种不同的面料用于流行的软标识应用,而热压机需要根据每种材料的理想设置进行校准。例如,较重的织物需要在压延过程中施加更大的压力,而颜色较深的阴影处则需要更多的热度。

Any lint or debris on the fabric should be removed before it goes into the heat press, using an air line. Otherwise, the inks will transfer onto these pollutants, rather than onto the fabric itself.

织物上的任何绒毛或碎片都应在进入热压机之前用空气管清除。否则,油墨就会转移到这些污染物上,而不是转移到织物本身。

If stray inks cause image overlays, then protective paper should be added to the heat press belt. This will prevent inks from one run overlaying onto the next.

如因油墨不慎造成图像的叠加,那么应在热压带上加防护纸。这将防止油墨从一卷织物叠加到下一卷。

Image distortion can occur if there is too much tension when the fabric is feeding through or when it is wound at the end of the dye sublimation process. Too little tension, on the other hand, can cause wrinkles. This is another example of why testing is so important.

当织物在染料升华过程中或结束时张力过大时,就会发生图像变形。另一方面,张力过小会导致褶皱。这是“为什么测试如此重要”的另一个例子。

Ink and transfer paper issues

油墨和转印纸的问题

The printing profile for a fabric is important in determining ink limits. Too much ink laydown can result in ‘ghosting’ (i.e. blurring), banding (i.e. unwanted stripes) or cockling

of the transfer paper.

织物的印刷轮廓对于确定油墨的限度是很重要的。过多的油墨会导致“重影”(即模糊)、条带(即多余的条纹)或转移纸的起皱。

The effectiveness of dye sublimation depends on proper settings for each fabric, which may best be determined through testing.

染料升华的效果取决于每种织物的适当设置,这可能最好通过测试来确定。

Indeed, with fabrics, more ink does not necessarily result in more vibrant colours. Oversaturation can lead to issues with ink bleeding and pooling.

的确,在织物上,更多的油墨并不一定会产生更鲜艳的色彩。过度饱和会导致油墨渗出和池化问题。

Another important factor in this respect is the quality of the ink. Dye sublimation inks are mostly water-based, but an ideal ratio will include about 60 to 70 per cent water content and 30 to 40 per cent dye and colorant content. Stabilizers are also added to keep the dye molecules from settling (i.e. sedimentation) or clumping (i.e. agglomeration).

在这方面的另一个重要因素是油墨的质量。染料升华油墨主要以水性油墨为主,但理想的比例将包含60%至70%的水含量和30%至40%的染料和着色剂含量。稳定剂还可以防止染料分子沉降(即沉淀)或凝结(即结块)。

With lower-quality inks, there is too much water and too little dye and colorant content, which leads to sign shops laying down too much ink in the hope of achieving stronger graphics. Inks are also specially formulated for specific types of inkjet printheads, with the ideal viscosity for jetting. Not all inks will work with all printheads.

质量较差的油墨,水太多,染料和着色剂的含量太少,标识商店为了实现更完美的图像色彩,会放置很多油墨。还有专门为特定类型的喷墨打印头配置的油墨,它具有理想的喷射粘度。并不是所有的油墨适用于所有的喷墨打印头。

The purpose of the transfer paper is to hold the inks and then release them during sublimation. It needs to be stored properly, as coated papers can be damaged by humidity. Another way to prevent such problems is cycling through inventory with a ‘first in, first out’ (FIFO) system.

转印纸的目的是为了保存油墨,然后在升华过程中释放它们。它需要妥善保存,因为即使是涂层的纸也会因湿度而受损。另一种防止此类问题发生的方法是使用“先进先出”(FIFO)系统循环库存。

The weight of the transfer paper is an important factor. Anything lower than 36.3 kg (80 lb), for example, will not transfer enough ink onto fabric for a lightbox application. A middle-of-the-road option may weigh about 95 g (3.4 oz) per square metre.

转印纸的重量是一个重要的因素。例如,任何低于36.3千克(80磅)的转印纸,都不能将足够的墨水转移到织物上,以供灯箱使用。转印纸最合适的重量可能是约95克(3.4盎司)每平方米。

New frontiers

新领域

While many fabrics have been optimized with soft signage applications in mind, the digital inkjet printing of fabrics also means sign shops can move beyond their traditional boundaries.

许多织物经过了软标识应用的优化,织物的数码喷墨打印也意味着标识商店可以超越传统领域的界限。

Home furnishings, especially, represent a new frontier. People love to be able to add custom features to their homes, but such one-off projects were simply not economical with screenprinting.

尤其是家居用品,代表着一个新的前沿。人们希望能够在自己家里添加定制的特色家居用品,但这种一次性的项目用丝网印刷就不经济了。

There are also commercial applications, such as digitally printed acoustic wallcoverings, which can provide visually elegant sound baffling for busy environments like restaurants, hospitals and schools. The opportunities are endless.

还有一些商业应用,比如数码印刷的吸声墙面涂料,它可以为餐馆、医院和学校等繁忙而嘈杂的环境提供优雅的视觉感受和很好的隔音效果。在商业领域里,织物数码印刷的应用机会是无穷无尽的。