There are several potential issues decorators may face when printing with UV inks, whether screen printing or digital printing. Let’s say you have a printer in good working condition, the proper UV or LED bulbs, and are using a quality ink. This article focuses on problems that the print operator can solve, so we need to put aside possible issues related to equipment, UV bulbs, and aftermarket inks. Ensure your printing surface is ready for printing to get the best print image, durability, scratch residence, water resistance, and even the ability to hold up to a dishwasher.

无论是丝网印刷还是数码印刷,凡是用UV油墨进行打印时,装饰师都可能面临一些潜在的问题:如何获得最佳的UV印刷图像?如何保证UV印刷品的耐用性、防水性、抗划痕甚至能够经受洗碗机清洗的能力?

本文将假设所使用的UV打印机处于良好的工作状态,具有完好的UV或LED灯照,使用的是优质油墨···并撇除一切与设备、UV灯泡和墨水可能造成的负面影响——在保证完美的打印条件下,着重于从人为操作的角度讨论各项措施会对UV打印产品的品质造成的影响。

Pretreat to a Get a Good Printing Surface

高品质的印刷,从预处理开始

The Problems: The ink bubbles or has pinhole gaps; the ink is easily scratched; there is no water resistance, or the ink comes off when containers are washed.

The Culprits: The surface of the printed material needs preparation, or the ink needs an adhesion promoter.

The Solutions: Pretreat the print surface to remove contamination and improve adhesion and/or add an adhesion promoter to improve the bonding of inks to the surface.

Let’s look at these two solutions separately.

问题:印刷结束后“油墨起泡或有针孔状间隙;耐刮擦性弱;防水性差,在普通清洗时发生油墨脱落”是什么原因,怎么办?

罪魁祸首:在印刷前未对印刷材料进行预处理;没有根据打印需要使用油墨助粘剂。

解决方案:对印刷表面进行预处理以去除污染并改善附着力,或添加能够增强油墨与表面粘合力的增粘剂。

The Print Surface

仔细观察,印刷表面

It is pretty easy to recognize dirty glass, dusty acrylics, or greasy metal and clean the surface. But sometimes there is contamination that can’t be easily seen; moisture, static, surface oxidization, even exposure to contaminants in the air can lead to adhesion problems.

人们往往能够轻易识别出脏玻璃、满是灰尘的亚克力或是沾有油污的金属,并对它们作出清理,但是有些时候,有些污染是不容易被肉眼发现的——水分、静电、表面氧化甚至是空气中细小的污染物都可能会导致UV打印的油墨沾附出现问题。

Step 1: Clean the surface

步骤1:清洁表面

This can be as simple as wiping the surface with paper towels, although this may not remove all the contamination, and it can leave behind lint. A better option is using lint-free towels or clean cloth rags with isopropyl alcohol. High-percentage alcohol works best because it also removes moisture from the surface.

这一步说起来非常简单,不过是用纸巾将表面擦拭干净——但仅仅这样做是无法去除所有污染的,并且可能会留下绒毛。更好的选择是使用不起毛的毛巾或干净的抹布,蘸上异丙醇(甲醚)进行擦拭,有高浓度的酒精效果最好,能够清除表面的水分。

Step 2: Test the surface

步骤2:测试表面

Printing on most surfaces requires good surface energy; this allows the ink to lay flat on the surface, avoiding pinhole gaps, bubbles, and other adhesion problems. Frequently, good surface energy is referred to as “wetting.” This can be checked using water or Dyne test pens. When using Dyne pens, for a good printing surface, we want to see a minimum of 40.

在大多数材质的表面上进行打印时都需要良好的表面张力,能使油墨水平沾附在表面上,从而避免出现针孔间隙、气泡或其他沾附问题。通常,良好的表面张力被称为“润湿”,该项参数可以使用清水或“达因测试笔”进行检验,“达因笔”检验的数值至少达到40才能被称为良好的印刷表面。

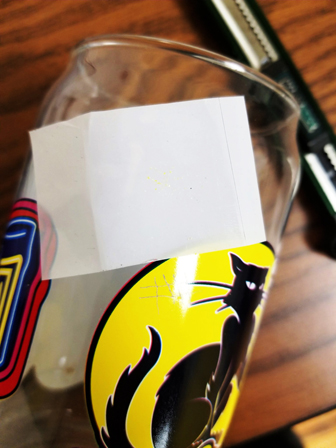

Pitchers that were sitting in a dusty warehouse for over a year.

在满是灰尘的仓库里呆了一年多的水杯。

Dyne pens usually come in sets and are available from many sources. A quick Google search offers dozens of purchasing options.

“达因笔”通常会以套装形式出售,购买渠道有很多,在搜索网站上就能找到。

On the left side of this image you can see an example of poor wetting — this surface is not printable. On the right is an optimum surface. Water has a Dyne level of 72, so this surface is exceptional.

On the left side of this image you can see an example of poor wetting — this surface is not printable. On the right is an optimum surface. Water has a Dyne level of 72, so this surface is exceptional.

通过这张图片,可以清晰地看出“润湿”的示例效果——左侧是不良的表面,不可进行打印;右侧则是最佳表面。该测试所用的“达因笔”等级高达72,因此可见该表面非常出色。

Step 3: Pass/Fail

步骤3:合格与失败

When you test with the Dyne pen, you want to see the ink lay flat, a continuous unbroken line — this is a pass. When the ink has gaps or bunches up, this is a fail, and you need to use another method to pretreat the surface.

在使用“达因笔”进行测试时,平整的油墨分布、连续而不间断的线条,意味着测试合格;反之,当油墨出现缝隙或堆积时,则以为着测试失败。这时就需要使用别的方法对表面重新进行预处理。

Step 4: Print or back to the drawing board

步骤4:开始打印或从头再来

If you have a good printable surface, go ahead and print. We may need to test for adhesion, but that will be discussed later.

如果已经具有良好的可打印表面,就继续进行打印吧,虽然可能仍需要测试粘附性,但这将在后面进行讨论与说明。

If the surface is clean, there are many materials that shouldn’t require any additional pretreatments, such as PVC, acrylics, Di-Bond, some plastics, untreated wood, cardboard, etc. Learning different materials requires some experience. For example, many promotional products that are purchased to customize with UV printing don’t list the type of plastic, so these need to be tested. As you gain experience, you will be able to identify many plastics by looking at them and will know if they need additional pretreatment.

其实,有很多只要表面清洁,就无需进行任何预处理的材料,例如:PVC、亚克力、复合铝材、某些塑料、未经处理的木材以及纸张等,想要准确地掌握这些材料的特性需要长期积累的经验,但这是有必要的,因为许多用于定制UV打印的促销产品并没有列出具体材质类型,因此需要对其进行测试,逐渐熟练后就可以仅凭表面来识别很多塑料,并知道它们是否需要额外的预处理了。

If you still have poor wettability, there are additional pretreatment processes to try and improve the surface.

···如果您进行到这一步后,所有材料的“润湿性”仍然很差,那么可以使用下面带来的其他预处理工艺来尝试修复。

Near the left side of the image is a “pass,” and on the right side, you see a “fail” when using the Dyne pen.

该图片上的痕迹,偏左侧附近是“通过测试”,而后半部分如果用“达因笔”测试,则会看到“测试失败”的结果。

Step 5: Other pretreatments

步骤5:其他预处理方式

There are a number of options available depending on the material.

其他的预处理方式,根据材料的不同分为很多选项。

Cleaning Products – sometimes 409 or Clorox cleaners are enough to clean the surface and give good wetting, but be ready with stronger cleaning agents. Automotive brake cleaners work well on some metals, but be careful that they won’t damage the surface.

清洁剂——对于一般材料来说,409清洁剂或Clorox清洁剂就足以清洁表面并使其具有良好的“润湿性”···同时也得准备使用更强的清洁剂,比如汽车刹车清洁剂在某些金属材质上的效果就很好,但得确保它们不会损伤表面。

Flame Treatment – many plastics and some glass respond well using a butane torch that can be purchased at your local hardware store. Glass can get very hot and plastic burns, but if you go over the surface fairly quickly, you can avoid excessive heat. Even thin films can be flame treated. Be careful: you are using an open flame, so clear the area of flammable materials, never leave a lit torch unattended, and have a fire extinguisher nearby.

火焰处理——在普通的五金店中就可以买的丁烷燃烧器就能够对许多塑料和玻璃材质进行完美处理,需要注意的是在进行这项操作时,玻璃可能变得很热,而塑料可能会被灼坏,所以在处理过程中要快速翻转材料表面——如果操作熟练,甚至薄膜材料也可以进行火焰处理。

警告:使用明火时,请清除周围的易燃材料;切勿让燃烧器无人看管;在附近放置灭火器。

Pyrosil is another form of flame treatment, although this is a proprietary technology that is used for a variety of pretreatment processes.

Pyrosil是火焰处理的另一种形式,这是一项专有技术,适用于多种预处理过程。

Pyrosil changes the surface by applying an invisible layer of SiO2 (silicon dioxide) onto the surface. The technology is recommended by Xerox, RUCO, Marabu, Norcote, Nazdar, Sun Chemical, and many other ink manufacturers.

Pyrosil通过在材料的印刷面上覆盖一层不可见的二氧化硅层,从而改变表面的性质,众多大牌油墨厂商:施乐、鲁科、玛莱宝、丽色达、太阳化工,和许多其他的油墨制造商都对该技术倍加推崇。

Pyrosil uses special butane cartridges infused with chemistry to create this new layer of SiO2. There are a number of burner systems available for Pyrosil, from small handheld torches, tabletop units for larger areas, or production and ever-automated flame systems.

Pyrosil工艺在热处理环节上,使用注入特殊化学物质的丁烷燃烧器释放火焰来创建新的二氧化硅层。有许多适用于Pyrosil工艺的燃烧器系统,包括小型手持式割炬、较大区域的桌面装置或自动喷焰生产系统。

Sometimes 409 or Clorox cleaners are enough to clean the surface and give good wetting, but be ready with stronger cleaning agents.

有时409或Clorox清洁剂就足以清洁印刷材料的表面并提供良好的“润湿性”,但以防万一,最好还是准备一些更强的清洁剂。

Many plastics and some glass respond well using a butane torch that can be purchased at your local hardware store. Always keep a fire extinguisher nearby when working with open flame.

许多塑料和玻璃都可以使用丁烷燃烧器进行处理,这种工具在当地的五金店就能购买。进行明火作业时,请始终在附近放置灭火器。

Instead of Dyne pens, water can be used to test wetting when using Pyrosil. Water had a Dyne level of 72, so if water flattens out, it’s about the best printing surface possible.

在使用Pyrosil工艺进行预处理时,可以使用水来代替“达恩笔”来测试“润湿性”,水的“达恩值”高达72,因此如果水在表面上变平,就可能是最佳印刷表面。

Pyrosil also creates high surface energy; this allows inks better chemical bonding. This means that Pyrosil can increase scratch resistance, durability, adhesion under wet conditions, and even make UV-printed surfaces dishwasher safe.

Pyrosil工艺还能增高表面张力,可以使油墨更好地进行化学键合,这意味着更高的耐刮擦性与耐久性,以及在潮湿条件下更好的油墨附着力,甚至可以使UV印刷表面的洗碗机更加安全。

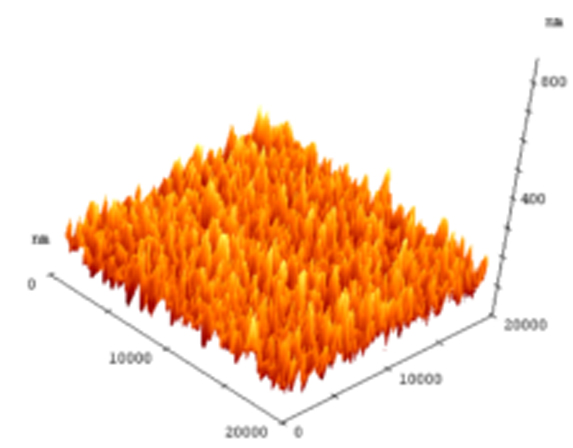

A magnified image of the Pyrosil surface.

Pyrosil工艺制作的印刷面的放大图像。

Adhesion Promotion: Making Ink Stay Stuck增强附着力:让油墨“乖乖站好”

· The Problem: The ink scratches off or comes off easily when wet or won’t withstand dishwashing.

· The Culprits: Digital inks do not contain hardeners, and the formulations may have weak chemical bonding.

· The Solution: Use an adhesion promoter.

· 问题:“受潮时,油墨容易被刮擦后轻易脱落;或者无法承受硬物刮擦”怎么办?

· 罪魁祸首:数码印刷的油墨一般不包含硬化剂,并且配方的化学键可能偏弱。

· 解决方案:使用增粘剂。

I am frequently asked if the surface is properly pretreated, why do I have ink adhesion problems? The most common issue comes down to the jet-able requirements of digital inks.

经常会有人产生疑问:明明已经对表面进行精心的预处理,为什么还会产生油墨附着力不佳的问题?最常见的原因往往是由于数码印刷油墨本身的可喷射性要求所导致的。

To ensure digital inks can be sprayed through the tiny nozzles in a print head, they must have a high viscosity. This means that they have not been able to integrate or add adhesion promoters or primers in the ink. Otherwise, it would clog the print head. The inability to add a hardening agent to digital inks is what makes them less adhesive.

在绝大多数的工业设计中,为了确保可以顺畅通过数码打印喷头的微小喷嘴,必须让油墨具有高粘度,这意味着无法在其中整合或添加硬化剂或底漆,否则就会造成喷头堵塞,但同时也不可避免地会使粘合性降低。

When do you need to use an adhesion promoter? To get to the answer, we must first ask ourselves, what are our expectations for adhesion? If you are printing on a candle, there may be very low expectations for adhesion because it is so easy to scratch and damage the surface. However, if you are printing on pint glasses that someone wants to use in their home or a restaurant, they are going to have to stand up to friction from stacking and a lot of dishwashing.

而什么时候需要使用增粘剂呢?这个答案需要根据具体的需求确定,即“产品对于附着力的要求是什么?”如果要在蜡烛之类的物体上进行打印,加入硬化剂的油墨很容易刮擦和损坏表面,因此对沾附力的需求不会很高;但是,如果要在家里或餐厅中使用的玻璃容器上进行打印时,就得考虑它们将会承受的堆积和清洗时产生的摩擦。

This leads us to how to test the adhesion of UV inks. The type of testing you do depends on what the printed item will be used for, but these are the most common types of tests:

· Scratch Tests – run a fingernail or a sharp object across the print surface.

· Cross-Hatch/Scoring Tests – use a razor or an adhesion test kit to cut a pattern into the ink and using tape to see how much ink can be removed from the surface.

· Water Tests – submerge items into the water and then testing for reduced adhesion.

现在有一种高效测试UV油墨附着力的方法,执行的测试类型取决于具体的打印项目,不过其中将包含最常见的几种情况:

· 划痕测试——用指甲或尖锐的物体划过打印表面。

· 交叉取样测试——使用剃刀或附着力测试套件将物体切割为“#”形,然后使用胶带粘贴并撕下,查看可以从表面上去除多少墨水。

· 防水测试——将物品浸入水中,然后测试附着力是否降低。

The type of testing you do depends on what the printed item will be used for.

所做的测试类型取决于项目的用途。

Types of failures:

· Ink is easily wiped off the surface

· Ink does not pass the water test

· Ink is easily scratched

附着力不佳的表现:

· 油墨很容易从表面擦除

· 油墨未通过水测试

· 油墨容易被划伤

So, the answer to, “When do I need to use an adhesion promoter?” is: as soon as the ink adhesion does not meet your standards.

“何时该使用增粘剂?”的答案是:“在油墨附着力不符合项目要求时。”

There are a number of companies that offer adhesion promoters. We have had excellent results with Marabu, INX, and Modico Corp. products. In addition, SURA Instruments also offers adhesion promoters specifically formulated for digital inks called SuraLink. Utilizing Pyrosil along with the SuraLink primers has passed 250+ dishwashing tests in a number of independent tests.

有许多公司都能提供增粘剂,其中玛莱宝、INX和莫迪康的产品都比较出色,此外SURA仪器还提供专门为数码打印油墨配置的增粘剂:SuraLink。许多第三方对SuraLink进行过测试,将其与Pyrosil工艺相结合,已通过了250多次的洗磨测试。

Note: Generally, UV screen printing does not require additional adhesion promoters because there is a hardener agent mixed into the ink just prior to the printing process. This increases adhesion and works well. Occasionally, we do run into situations where UV screen printers need exceedingly high adhesion and then we recommend an adhesion promoter.

需要注意的是,通常UV丝网印刷不需要额外的增粘剂,因为在印刷过程之前,油墨中已经事先掺入一部分硬化剂,这样增加附着