Since being in the sign making business can include just about anything and everything -- from working with wood, metal and plastic to multiple forms of printing and engraving, in 2D or even 3D -- there is never an end to buying tools and equipment. Being in the business for more than 40 years certainly does not mean we have everything we want, or even need, and our wish list always has something on it.

在标识制作领域,你可以接触到任何材质的标识–比如:在木头、金属、塑料上制作,到打印或者雕刻不同形态的标识,甚至你从不停歇要购买2D或者3D 这些打印工具和设备,以满足你生产发展的需要。我们在这个行业超过40年时间了,这并不代表我们拥有所需的一切,总会有一些东西在我们采购的愿望清单上。

But this past year, without having a real game plan as to how we would put it to work, I decided to take the plunge and buy one big-ticket item I had been looking at for years but had not yet purchased: a laser engraver/cutter.

虽然在过去的一年中,并没有一个真正的计划能让我们把愿望实现到工作当中,但是我决定投入买一件昂贵的,一直寻求多年但并没有购买的东西–一台激光/雕刻切割机。

And it really is an engraver/cutter, because with enough wattage a laser engraver certainly can do highly precise cutting on a variety of materials, and engrave a wide range of engraving media as well as a whole host of standard materials that have the potential to be laser engraved.

这是一台真正的雕刻切割机,因为它有足够的瓦数可以在不同的材质上做很精细的切割,并且可以在很多不同可雕刻的介质上进行雕刻,就像一整套标准的材料拥有强大的激光雕刻潜力。

We are still finding our way into the laser engraving/cutting business, but before I decide to slow down a bit and let the shop run without me at least some of the time, the time was right to get this new toy on the road to being paid for so it can be a valuable asset to our commercial sign business, whether I am present each day or not. And, over the years I have proved this several times: if I wait until I am forced to buy a piece of equipment and until I know exactly how I intend to use it, I have waited several years too long already.

虽然我们仍然在寻找利用什么样的方式来,能更好的获得激光雕刻/切割生意,因为这台设备对于我们商业标识公司来说可谓是一项宝贵的财产,在过去的几年里,我已经证明了很多次:如果我等待直到被强迫去购买一台设备,并且知道真正需要用的时候才去购买,那我已经等了好几年了。但在此之前我决定放慢一点脚步,利用这段时间正好可以测试那台新的设备。让店面在没有我的情况下也继续正常运作。

Of course, with any significant equipment purchase, the last thing we ever want to do is spend real money on a machine only to find that we did not get the size, capacity or power we really needed. Our unit, made by Trotec, is a 120 watt machine and has a usable area of 24” x 39”, so the power and table size will accommodate just about any type of laser work we will need to do, which was certainly our intention when we became serious about buying a laser.

当然,在购买任何重要设备的时候,我们曾经都要做的最后一件事是花钱在一台设备上并没有得到我们所想要的尺寸、容量或能力。我们的那台设备,由Trotec公司生产,是一台120瓦的设备,并且可应用的范围在24英寸x39英寸。这台设备的能力和可切割的尺寸可以完成我们所需要任何类型的切割工作,这真正是我们当初购买这台设备的意图。

For a beginning user, a modern laser engraver/cutter is not a really difficult thing to learn, but one surprise I had was how much exhaust ducting is really needed to keep the ventilation where it needs to be. When setting up a laser, having the required amount of vented air flow, or even more, is a very important factor.

对于一个初级用户来说,学习使用一台激光雕刻/切割机并不是一件非常难的事,但是真正要学习的是有多少废气要排放并且我们要怎样保持通风的需要。在安装一台激光机的时候,需要找一个气流通风的位置,这是非常重要的。

We bought a vent fan unit with plenty of horsepower, and mounted it outdoors on the other side of an exterior wall, and had it wired to a switch right beside the unit. Since virtually all materials, when laser engraved and especially laser cut, emit considerable fumes or smoke, having a very capable exhaust system is a first priority, and it is critically important for the safety and health of our employees, and even the health and care of the machine itself.

我们购买了一个马力足够大的通风机,安装在户外外墙的另一侧,并且在设备的旁边也安装一个开关。因为基本所有的材质,只要设备进行激光雕刻特别是激光切割,就会释放出相当大的烟雾或者气体,有一个非常强大的排气系统是首要的。这对我们员工的安全和健康非常重要,并且对保护设备本身来说也是一样。

At our commercial sign shop, we digitally print, screen print, make vinyl graphics, do rotary engraving and have access to a CNC router and a waterjet, so there is a lot of ways we can mark, print or cut something. Our laser fills a gap, but it is a gap we are still exploring.

在我们商业的标识店面,我们可以做数码打印、丝网印刷、制作背胶、做旋转雕刻并且可应用CNC切割和水喷射切割,因此我们可以以很多不同的方式进行制作、打印或者切割一些东西。我们新的激光设备填补了这一空白,但是我们仍然在探索这一填补区域。

Interestingly, some of the things we've found to do with it are not typical sign products, but this is to be expected with a laser engraver/cutter. Several of the photos here show a very small portion of the atypical uses one can find to do with this type of equipment.

有趣的是,我们发现我们做的有一些东西并不是一些典型的标识产品,但是这些产品都可以在我们的激光雕刻/切割机应用上。这里有几张图片都展示了非常少的一部分非典型产品我们可以使用激光雕刻/切割设备制作。

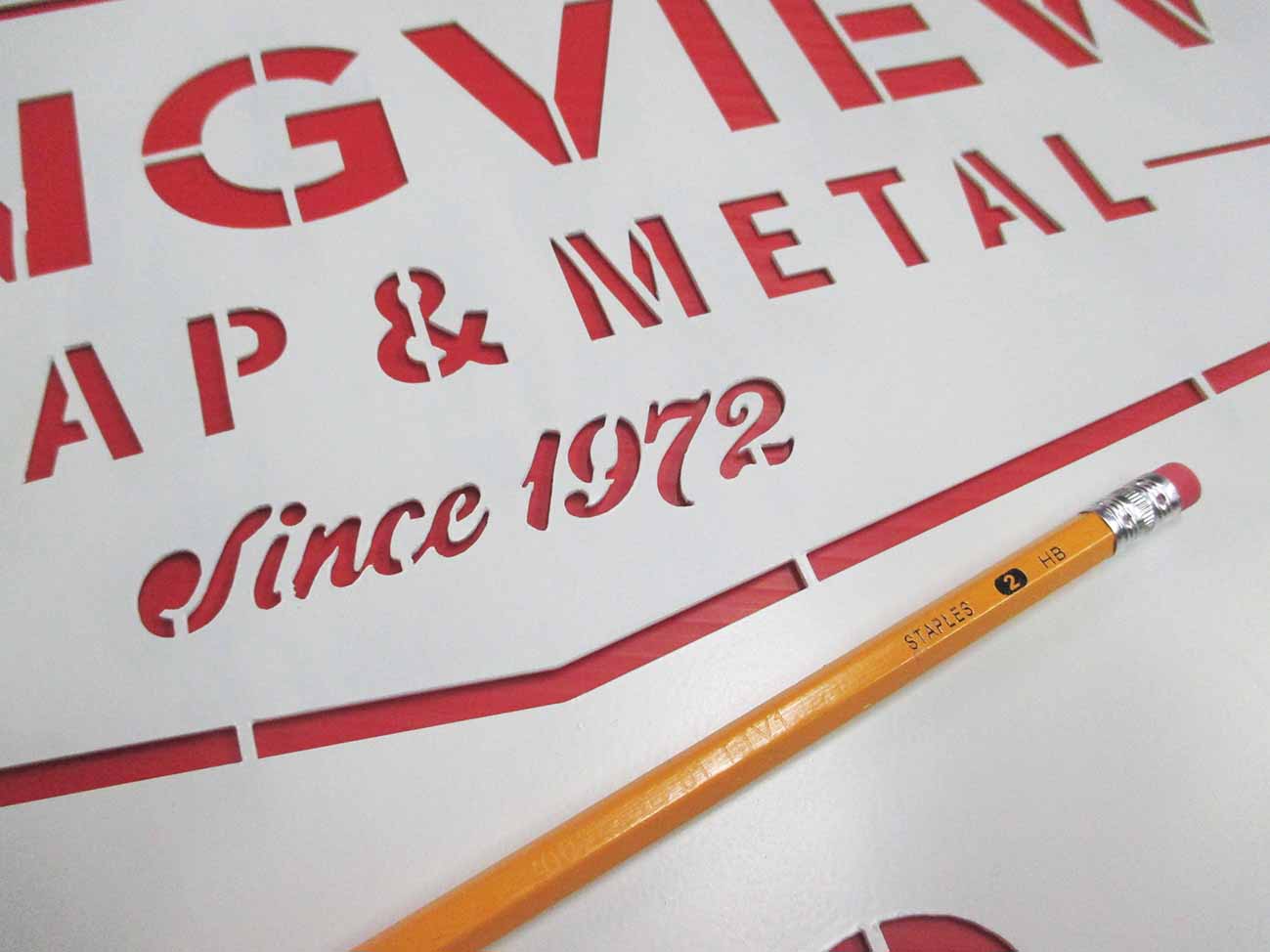

From team sport zipper pulls given out as gifts at Christmas, to clear Plexiglass “makeup pallets” used by photographers and makeup artists, to stencils cut with extreme precision and intricate detail not possible by any other means, what can be done with a modern laser unit is mostly limited by the user’s imagination.

从制作圣诞礼物的运动团队拉链扣,到摄影师和化妆师所使用的透明有机玻璃“化妆托盘”,对于非常精细的模板切割和复杂的细节不能使用其它设备,但却可以通过用户的想象用一台现代激光设备进行完成。

Of course, cutting acrylic plastic letters and logos from sheet stock up to ½” thick is easy work for a laser with enough wattage, but it will also cut the install templates simply and cheaply in poster board stock or similar paper material … and fast. Though a unit that is less than 4’ wide will not make large install templates, they can easily be done in sections and taped together to make just about any size required.

当然,一台激光切割机在厚度达二分之一英寸的板材上切割亚克力塑料字母和标志是非常容易的,在招贴纸板或相同的纸材质上进行模板切割也是非常简单和廉价,当然也是非常的快。虽然设备少于4英尺宽并不能制作很大的安装模板,但是它们可以分不同部分切割并组合在一起,组合成任何所需要的尺寸。

A somewhat creative project we did for a local school featured quite a bit of laser cut acrylic elements, and is shown in the accompanying photos. Producing the main graphic elements, in black .25” acrylic, beautifully cut with flame polished edges, was the simplest part of this custom sign project.

我们为当地学校做了一个很有创意的项目:为一些亚克力制品进行激光切割,并在附上的图片上显示。在黑色25英寸亚克力板材上做图像切割,非常漂亮的切割与边缘抛光,这是标识定制项目中最简单的一部分。

Even though there is a variety engraving stock manufactured for both laser and rotary machines, and a lot of it works with both types of engravers; there are sign shop materials that are not engraving media but can still be engraved.

尽管在激光和旋转设备上制造过各种各样的雕刻产品,并且很多的作品都可以使用两种类型的雕刻机。有些标识店的材料并不是可雕刻的材质,但也仍然可以在上面进行雕刻。

Recently we did an order for a manufacturer of deer feeders and hunting stands, and laser engraved 1,000 metal tags in pre-finished brown and green aluminum sheet. Nothing beats the detail of laser engraving and the permanence of the marking, or even the low cost for us to produce them.

最近我们接到过一个为养鹿和狩猎站服务的制造商订单,要在已经处理的棕色和绿色铝板上激光雕刻1000个金属的挂牌。没有什么比激光雕刻的细节和标记的持久性更好,或者甚至以最低的成本来生产它们。

Tags of various kinds for manufacturers are a big part of our intended use for our laser -- that much we know. But what we don't know, but are finding out day by day, is how many other uses and can find for it, and how it will fill that void in our capabilities and help us run a more efficient and more profitable sign business.

制造各种各样不同的标识,是我们使用激光雕刻设备的主要部分–这是我们知道的部分。但是我们不知道的是,慢慢你会发现,我们找到很多其它领域的用途,这不仅可以填补这些空白市场,并且可以帮助我们标识的生意更加有效和有利可图。

One thing is for sure, it's going to be interesting to work through this learning curve and explore our little corner of the world of laser engraving and laser cutting. These days, signmakers get to play with some pretty cool toys, and that’s OK by me.

有一样东西可以确认的是,通过对雕刻和切割字体角落的弧度、探索学习,你会发现这是一项非常有趣的工作。然而,很多标识制作者都在使用一些很酷的设备。生意是需要不断的探寻和摸索的,相信你也可以。