I am not really a one-man army, since we normally employ over a dozen full- and part-time employees at our two companies located across the highway from each other. But, when I go back through my files it is interesting how many sign fabrication jobs I tackle personally and get done with very little help from the crew. And to be honest, I don't mind flying solo at all.

我们公司在当地颇具实力,横穿高速公路两侧都属于我们公司的区域,因为雇佣全职或者是兼职的员工,所以,这让我们的公司看起来人数非常多。但是,当我回首过往的经历时,我会发现有意思的一点是,很多的标识项目都是我亲自处理,而很少获得到团队的帮助。实话说,我完全能够凭借自己的能力完成工作。

In fact, for quite a while I had two kids off to college, and working a whole lot of overtime seemed the only way to protect what retirement savings I had. Then, custom sign projects became my regular Saturday activity. This is often still the case today, because when I am not interrupted 30 times a day by phone calls, and customers who want to see the boss, I can actually get a whole lot done and I enjoy the work a lot.

事实上,在相当长的一段时间内,我有两个孩子刚刚走出大学校园。所以我拼命加班是为了在退休后能够有一定收入。那时,商家的标识项目占据了我所有的周六时间。我经常会一天接到30个工作电话,并且要经常的和客户对接。虽然每天有很多事情要做,但我却依然非常享受我的工作。

This month I'd like to look at a couple of the recent jobs that were basically created one-man-army style, and go over some of the fabrication techniques that make these jobs make sense and make money, too.

最近,我发现我近一个月的标识产品都含有我强烈的个人风格,而这些产品既让我感受到了人生的价值,同时赚取了不错的利润。

First of all, over the years I have found that I have gravitated toward building nearly all of my individual custom sign jobs using metal, and have half my wood working tools in storage. And most all exposed metal will be aluminum, of course. But, fabricating with metal is easy, with basic welding and cutting tools, and done right, many of the jobs are even still quite light and can be installed without lifting equipment.

首先,我从这么多年来的工作经验得出,我的工作已经开始向建筑业倾斜,所有的工业标识上的合作伙伴都在使用金属材质,当然这里暴露在外的金属都是铝型材质的。用基本的焊切以及切割工具能够使得金属材质的加工比较容易处理。而且制造出来的产品大部分都会比较轻质,并且无需吊装设备就可以进行安装。

One of the ones completed recently was a custom sign for a local plumbing shop called Richard Parker Plumbing. This client wanted a nice sign, somewhat three-dimensional, but was opting to light it from the ground so no electronics would be involved.

我最近的完成的企业标识中,有一家是为了当地的一家名为Richard Parker Plumbing的水暖店来设计的。这家客户想要一个优美的三维立体标识。但是企业最重要的需求就是要让这个标识立在地面上,并且要让它看上去没有任何电线连接到这个标识上。

Using his circular logo, I drew up a proposal that would present his name, phone number and even the address, on a tall monument sign with a steel structure, formed aluminum panels and simple cutouts. The final look would compliment his new building, install in sections without any real equipment, and last for years with all powder coated metal components and a concrete board covered pylon.

我们继承了他圆形logo的造型,并在设计方案中加入了他的名字、电话号码甚至是店铺的地址。这些信息都会放置在一个较高的金属标识上,它将由铝型面板和一些简单的切口所组成。最终的展示效果将会很好的在展示他企业的形象。我们将这个标识分为了几个部分,以使得安装将不需要一些大型的设备,而粉末涂层的金属以及混凝土板的结构能够让这个标识使用数年。

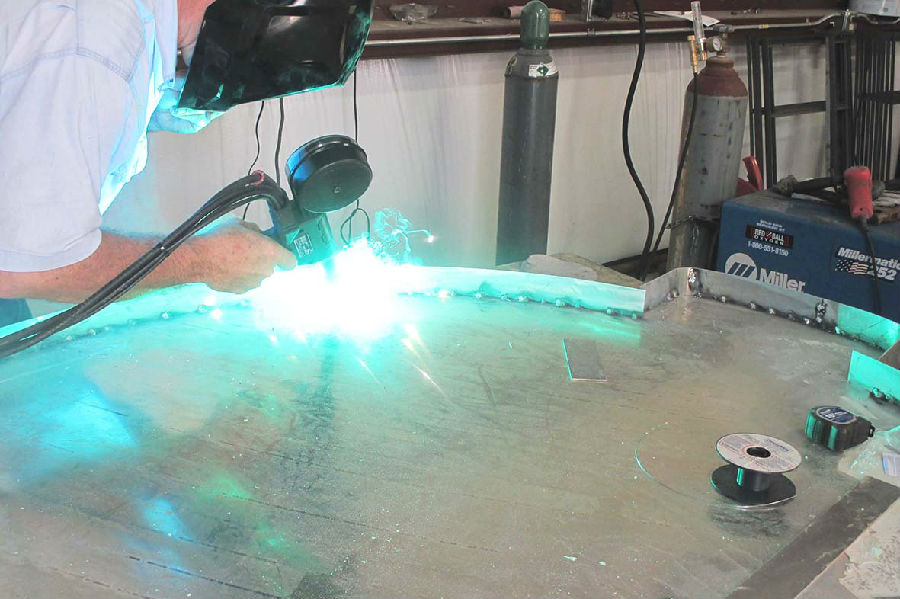

Also, this sign would involve a skill I was still working on, that is welding aluminum with a spool gun fitted to one of our wire-fed welders.

另外,这个标识将还包括一个我正在研究的技术,就是将焊接铝卷轴枪与我们的线轴枪相结合。

This was a fun job, and though the aluminum welding was a bit challenging (nothing serious, though, just spot welding), the whole process was just a tinker-toy puzzle that went together quite easily.

这是一个非常有意思工作,尽管铝的焊接有一些难度(在这里面要用到的技术是点焊接)。整个过程就像是一个又一个小拼图,只要将它们拼在一起,一切就一目了然了。

The structure for the pylon, which supported the entire sign, was built simply and from materials not often used in signs. That is, for lightweight strength, instead of using heavy c-channel or steel tubing for the main uprights, purlin steel 10” wide normally used in steel building construction was used. This metal comes primed already, is economical and lightweight but clearly strong enough, and that material was mated to some steel angle and square tubing to construct a simple framework.

支撑塔的结构将要支撑起整个标识,将被一些轻质并且不会经常使用在标识上的材质来制造。也就是说,我们会使用一些轻质的材质来代替这些重的c-管道或是一些钢管用于主立柱。而之前10英寸宽的钢结构则通常会在建筑中使用。这种金属结构在使用之前就已经制作完毕,既经济又轻便而且强度非常高。并且这种材质配合一些带角度的钢管和方管就能够制作出一个简单的框架。

The structure was built on our sign fabrication table, which is 6'x 12'in size, plenty large enough for this job. Even though it is welded on all the time, its top is made from thick particle board top, and things are often screwed to it to hold them in place while welding.

这种结构将会在我们的标识制作台上先被制造出来,他的尺寸是6 x 12英寸,并且它的尺寸要足够的大才可以支撑起整个标识。其顶部是由厚的发泡板支撑,而这个部分需要被焊接时固定到合适的位置上。

One handy tool we use for jigging up jobs like this, is a shop-made speed square, 12''x 12''made of .125 plate steel cut very precisely on a waterjet and welded with a lip all around like a smaller speed square.But this square can be tack welded,too;it can be screwed into the table top using holes in its wide lip, and is just a better item than can be bought at any welding supply.One of the photos shows this shop made square, and it is as handy as a pocket on a shirt.

现在建造的这个钢结构,它是由 12英寸×12英寸的水刀精确焊接和切割的.125钢板,在边缘焊接方钢坯料时你可以采用点焊的方式;这样,它可以在边缘上凿洞被安装在工作平台上。由于焊接设备易于购买,所以这种方式会让你的标识加工更加的便捷,其中就有一个图片展示了这个商家可以生产这种产品,并且就像缝制衬衣口袋一样方便。

The main structure was quite simple, and was cross braced for stiffness, but rather lightweight and could be lifted by hand, though I did have a helper when we got to that step.Fabricating the main logo panels, which were hollow and 2” thick, using our new aluminum spool gun, was the most interesting part.

其实它的主要结构相当简单,并且交叉使用以使得结构更稳固。尽管当我们到了这个步骤的时候,我也会有一个助手来协助我。但是相对于其它材料它还是非常的轻质,甚至用手就能抬起。制作2”厚主标识面板时我们会使用新的铝阀芯枪,这也是最有趣的部分。

Thankfully, all the welds were just spot welds that held the aluminum 2”wide stripping in place to form the edges of the round-shaped panels. Working by myself, it took less than half a day to have both of them assembled, and the ends welded into two large rectangular panels as well. Tack welding with the spool gun was fun, but that's where my skill level ends with aluminum welding.

所有的焊接点都是点焊接,这里需要保留出2”宽的距离,形成圆形管道的边缘。通过不到半天的时间我们就让这两部分组装了起来,并且焊接形成圆形面板的边缘。阀芯枪点虽然很有趣,但是我的操作水平也只能使用铝型材质的焊接。

All the exposed metal parts on this job, made from .090 mill finish 5052 aluminum, would be finished by powder coating. But to remove all surface oils and oxidation, every square inch was buffed out with a fiber disk of the right grit size. The ones we use are made by Norton, maroon in color, and I believe they are described as A/O Med HS. These fiber disks do a great job on aluminum prep work, but are not too aggressive so they do no damage. They are the best thing we have found for prepping mill finish aluminum prior to painting or powder coating.

所有在外暴露的金属部分都是由0.090光面5052铝材制成,并被粉末涂料所覆盖。但是为了去除掉表面的油脂和氧化物质,每平方英寸都进行了光纤磁盘抛光。那些物质都被我们用Norton以及栗色进行了制作,我把它们形容为A/O Med Hs。这些光纤磁盘在对铝材质的前期准备过程中表现地非常出色,这些过程我们都尽量做到循序渐进,以保证它们没有损伤。它们是我们找到光面铝制中最适合粉末涂料的材质。

Two more formed aluminum panels were made to construct the part of the sign that would display the phone number, as well as a flat cut-out piece for the address number. All these parts were cut on a CNC machine (waterjet), and the cut file included small notches indicating exactly how they were to be formed on brake, no mistakes allowed.

超过两个铝制板将被组合在一起使用,用以建造标识上展示电话号码的部分,扁平切口的部分,用于展示地址部分。所有的这些部分都会在数控机床上用水刀进行切割,并裁切掉那些小的缺口的部分。这些过程能够展示出他们是如何制造形成的,在这个过程是不允许出现任何的失误。

When the parts were finished and prepped for coating, I did the powder coating myself at our WPC Services facility, easily borrowing the equipment on a Saturday.

当用于标识的每一部分都准备好之后,在进行到喷涂的部分时,我们的WPC服务设备开始了粉末喷涂,就能保证在周六的时候设备被使用。

Out in the field, the pylon unit was set in the ground in hand-dug holes, and several bags of concrete mix were used to make it permanent. The unit was to fit on very sloping ground, so one side and one leg was longer than the other to accommodate the slope. Full 4x8 sheets of Hardie textured concrete board were used for the skirting, and they too were cut on a considerable angle at the bottom. For non-masonry monument structures, this sheeting is really ideal. It is inexpensive, paintable, extremely durable, and many of our monument signs are skirted with this material.

在安装现场,塔架在预埋好的地基上已经被搭建好,并使用了几袋混凝土以使得能够长期使用。这一部分要倾斜地面,所以一边的一个支架要比另一个要长,以适应这种倾斜的地面。Hardie式4x8的板材网纹混凝土被用于踢脚,同样,他们也被进行了一定角度的切割以适应倾斜的地面。对于非砖石结构的座式标识,这种薄膜的效果是非常理想的。它具有价格低廉、喷涂性强并且非常的耐用。

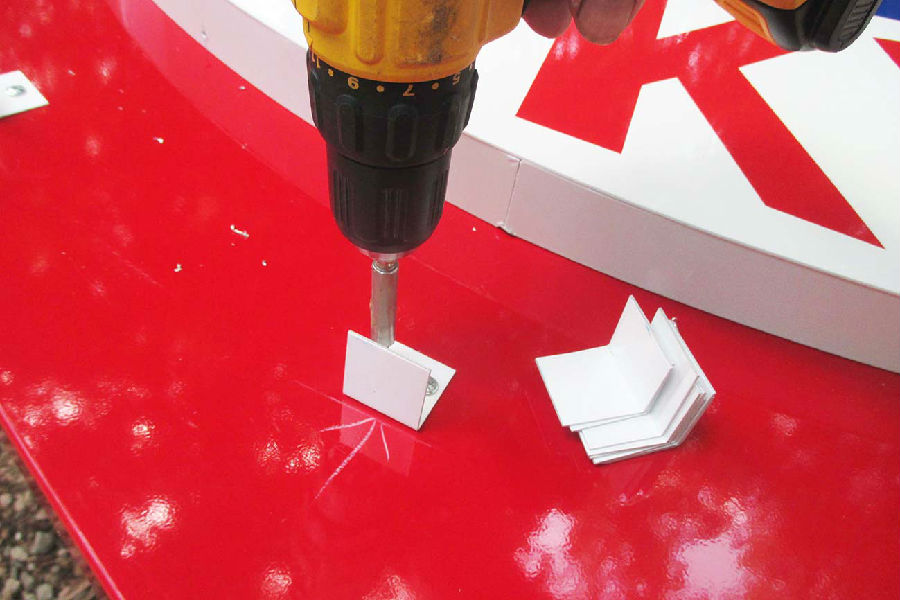

The pylon was painted to match the client's building, and the powder coated alum parts were installed one at a time, all lifted by hand as none were too heavy for manual lifting. Sheet metal work enclosed sides of the main elements, and a single 15”wide by 60”long piece of white .040 aluminum formed the“roof”that enclosed the top. A lot of the metal elements were secured by sheet metal screws, which had been powder coated to match the sign exactly.

这个指示塔被喷涂以适应用户本来的建筑风格,并且粉末涂层部分要一次性被安装好,再用起重器械来进行操作。金属板材围在主要支架的两侧,并且一个15”宽60”长的白色的0.040构成铝型封闭的顶部。很多金属基底都要有金属板螺钉安装以确保稳定性。

That job was a fun job, and involved work done over three Saturdays, but many of the hand fabricated jobs I do aren't that involved or time consuming. Another recent job I enjoyed doing from the ground up was for a local hair salon. Again, their logo lent itself to being cut into a shape, which was done in .125 aluminum sheet, a simple cutout, not formed. To provide a base to mount the sign on, a monument base was built of steel tubing, which would be covered with concrete board like the plumbing sign.

这个工作是一份有趣的工作,尽管需要牺牲周末来进行。许多需要手工完成或者是极费时间。另外,我比较有成就感的项目是为当地的美发沙龙提供服务。同样,它们的标识也需要被切割成需要的形状,将其在.125铝片上做一个简单的切口。从而为标识的安装提供一个基底,一个座式标识的基底需要用钢管建造,覆盖着类似于管道标识的混凝土层板。

The dimensional unit the actual sign would mount to was formed from mill finish .063 aluminum sheet, made into a hollow box that would slide down over tubing stubs extending up from the base.It literally would just sit in place,and the sign face cut-out is secured to it with about 10 counter sunk screws painted to match.This hollow raceway allowed the sign face to protrude out from the base,but is totally concealed by the sign, at least from the front side.

三维立体的部分将用一些光面.063铝板来组成,并且它会被制作成一个中空的盒子,以使得能够在基底延伸出来的管子上滑动。当它被放置在正确的位置之后,标识被切割过的正面也将用十颗被喷涂过的埋头螺钉进行固定,以便于后面的安装。这个中空的通道能够使得标识的正面从基地伸出,而且起码在标识的侧面观看的话,这一部分是完全被遮挡的。

One thing done to keep the public safe, and keep us from being liable,was to alter the sharp ends of the sign that extended out from the base. Since the sign face was only 1/8”thick, and someone might at some time bump into it,the exposed edges at end pieces were cut and secured in place.That doubled the thickness of the metal,eliminating a sharp and hazardous edge. Sign makers should consider safety issues like this at all times,for the sake of the public and themselves.

我们还要避免标识的不安全性影响市民的安全,所以我们对标识从基地伸出的尖锐末端进行了调整。因为标识的正面只有1/8”厚,并且很可能会有人在一不小心的时候就碰到它,所以那些突出的边缘将被切断以保证安全。这一步将会使得金属的厚度成倍增加,以去除锋利和危险的边缘。标识制造者也应该把安全问题做为自己的职责之一,为公众的安全以及自身的长久利益着想。

How awful it would be to work as hard as we do,to see all our income vanish because of an unfortunate accident and lawsuit. Working smart can be more important than working hard,and I know all about the working hard part.

如果因为安全问题导致灾难的发生,我们的盈利也就会化为乌有,所以就这点来说,有远见要比工作地努力更加重要,当然,努力仍是必不可少的。

But,at least our work is enjoyable, and if done efficiently and productively, and at times“one-man-army”style,it is profitable as well. That's how it is supposed to work,anyway. And built-by-hand projects,like the ones shown here, are some of the kinds of work I enjoy,which keeps me out of trouble and keeps our commercial sign business healthy in the black.

但是,如果我们的工作可以被高效和有创造性的完成,我们的工作依然是很令人享受的。尽管有时我们的工作需要一人来完成,但它依然利润丰厚。而那些需要手工完成的项目,也是我喜欢的一种类型的工作,它能够帮我跳出一些工作困境,并让我们的标识产业健康发展。