A couple of weeks ago I worked in tandem with another sign shop to install a fairly large all-metal sign. Matt,the owner of that shop,a friendly competitor,used his sign crane to lift the sign,and I used my manlift to position me for the hands-on part of the installation.

几周前,我和一个标识公司合作,安装一个大型金属材质标牌。公司老板Matt,是一个友好的竞争对手,用他的起重机吊起标牌,而我则由升降机上升到合适的位置进行安装。

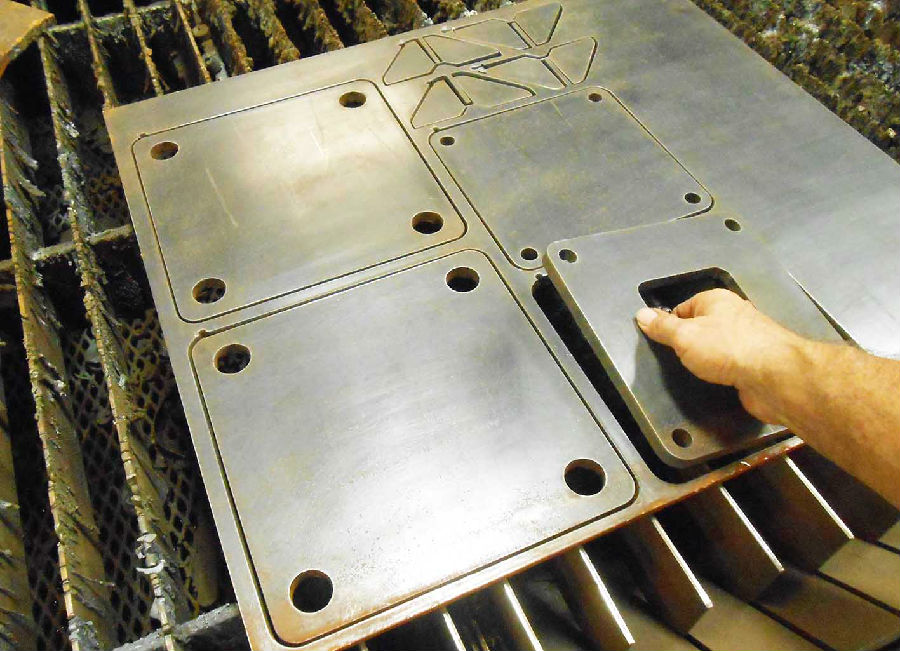

While he was there,Matt looked over the way we had built the sign posts,secured to large leveling bolts welded to the top plate of short stubby posts that were concreted in the ground. Both sets of plates and gussets were made from ½”thick steel, and all cleanly and identically cut on a CNC plasma table.The welding, done by my 82-year-old dad,was obviously strong and he was impressed at how well built the sign structure was, and asked me how we made the parts.

Matt站在那儿观看我们制作标志杆,将大平螺栓固定焊接到浇筑在地面的短柱顶板上。所有的板和角板都是用CNC等离子机从½''厚的钢板上切割下来的。焊接部分是我82岁的爸爸做的,看起来非常牢固。显然这个标志结构的良好构建让Matt印象深刻,他问我是如何做的这些部件。

Of course,making the parts was the easiest thing, since all was cut on a high definition CNC plasma table,and in fairly short order.Since our sister company does that type of work, I volunteered to have them make any structural parts he needed fast and at a fair price anytime.

当然,这部分是最容易的事,因为所有的零件都是在高性能CNC等离子机上进行切割操作,过程中只需要输入简短的命令。我们的姊妹公司就做这种类型的工作,当我需要他们提供的一些结构部件时,他们会很快做出,而且价格公道。

Today,with the computer driven equipment that is available most any place,it simply does not pay to do much cutting of steel,or anything else,by hand.And these CNC machines of various types have certainly gotten better over the years.

如今,以计算机驱动为导向的设备随处可见,不需要我们花费大量的时间用双手去切割钢材或其它材料。这些年,各种各样的电脑数控机器已经发展得越来越成熟。

Most sign shops are familiar with CNC router cutting,and maybe a bit less familiar with other types of computer controlled cutting,but let's take a little time and look at what a CNC plasma cutting table can do,and how best to use this type of technology for sign shop work.

大多数标识商店对CNC机床切割技术都很了解,但可能对其他类型的电脑控制切割系统却不太熟悉。接下来,让我们一起来了解一下CNC等离子切割机的功能,以及标识商店如何更好的使用这种技术。

Fortunately,to take advantage of a quality plasma table this day and time, one doesn't have to own one as the proliferation of this type of machine has made finding a subcontractor easy to do in most areas of the country. AtRick's Sign Co.,we would merely have to walk across the street for finding a source for high-quality plasma cutting,but most sign shop managers would not have to look far.

幸运的是,现在想要使用高质量的等离子切割机,在全国很多地方都可以很容易找到分销商。因为随着这种类型机器的普及,同时,不是所有的公司都需要自己购进这种设备,大多数标识商店都不需要找太远,在Rick's Sign 有限公司,就可以寻找到这种高质量等离子切割机,你只需要穿过街道即可。

Nowadays,there are standard plasma tables,and also high-definition plasma tables,which can cut with something approaching the accuracy of a waterjet (though not quite).All of this is really amazing as the stream that does the cutting is“plasma,”or a gas-like matter caused by the combination of a stream of an inert gas and high-voltage current,and the plasma created can reach temperatures of 25,000 degrees Celsius or more.

如今,有标准等离子切割机,也有高精等离子切割机,切割精确度接近水切割机的精确度(尽管不是完全接近)。切割使用的介质是“等离子”,惰性气体和高压电流混合产生类似气流的流体,等离子引起温度升高达到25000摄氏度甚至更高,这一切都太神奇了。

For sign shops,plasma cutting can be used for the obvious purpose of accurately cutting plates,flanges and gussets from structural steel,and also for cutting decorative pieces that will be welded to a larger steel structure,and even plate steel letters like some of the examples shown here.With the accuracy of many of today's plasma tables,fairly complex and delicate items can be cut if the computer file created to produce the items is prepared correctly.

对于标识商店来说,等离子切割技术显然可以用于切割钢结构的板、盘和角板,也可以用来切割焊接在大型钢结构上的装饰碎片,甚至是切割随处可见的金属字。随着现在等离子切割机精确度越来越高,相当有难度和精致的项目都能切割出来,只要提前在电脑里设置好合适的程序。

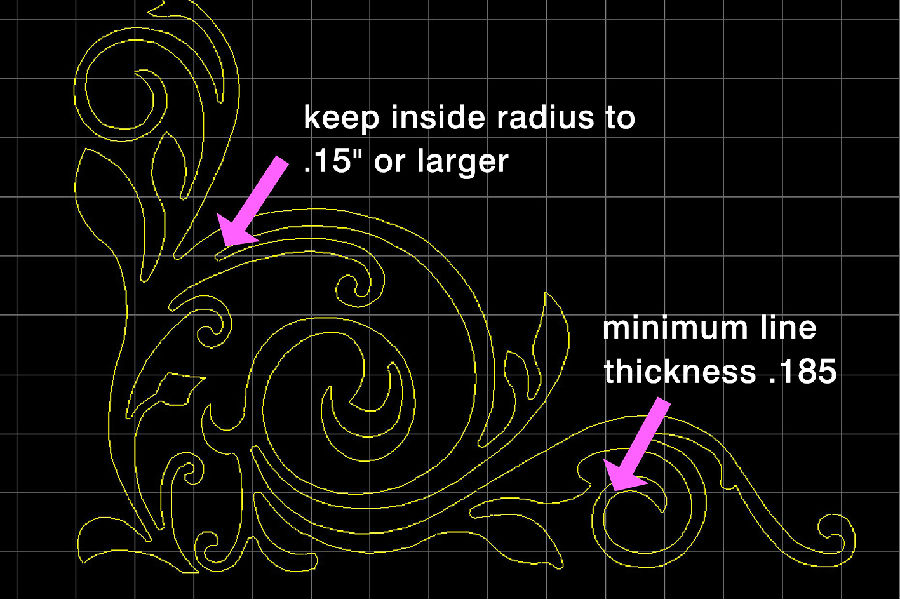

In this case,“correctly”means having the right tolerances for small inside cuts,reasonable line thicknesses and so forth.The scroll work we recently produced for a small custom sign makes a good example of what is possible with a high-quality CNC plasma table.

在这里,“合适”意味着正确的偏差范围、合理的厚度要求等等。我们最近为一个小型定制标识生产的卷轴,就是高质量CNC等离子切割应用最好的案例。

After preparing a file that I knew would test the limits of the Messer Plasma Cutting table we would be using,we cut a test item from .25”thick mild steel.The machine cut through the steel like it was cutting butter,but the final quality of the cut was less than ideal,due to the faulty computer file I had created.The inside cuts were too tight(at least for the standard cutting tip we were using),and some of the line thicknesses were so delicate as to cause some cutting problems as well.

使用之前,为了测试Messer 等离子切割机的极限值,我们设置了一个程序之后,用机器切割了一个25''厚的低碳钢作为实验。这台机器切钢板就像切黄油一样容易,但最终切割品的质量并没有想象中完美,因为我在电脑程序设置上的失误。内部切割太紧密(至少对于我们使用的标准切割端来说很紧密)、线条厚度太微妙,也导致切割出现问题。

With the second computer file,which worked beautifully the first time,I had merely made sure that all line thicknesses were something close to 3/16”thick,and the inside cuts and dead end radiuses were .15”or larger.Maintaining these simple parameters, at least when working with .25”thick steel,were all that was needed to allow the plasma table to do some beautiful cutting on my decorative parts.

第二次计算程序非常成功,机器第一次完美运作,我只是确保所有的线条厚度接近3/16''厚,内部切割和终端半径是15''甚至更大。保持这些简单的参数,尤其是在切割25''厚钢板时持续保持,就是利用等离子机切割装饰部件时我所需要做的。

The four decorative scrollwork pieces were all identically perfect,and the small amount of slag that a newer high-quality plasma table leaves on the back is not a real factor as it is very easily removed.Because these were steel,they could be welded directly into the square tube steel frame we had built for this job.The entire frame was blasted and heavily powder coated for extreme durability.

四个漩涡形装饰部分全都很完美,更新高质量等离子切割机留在背面的少量残渣不成问题,因为很容易去除。这些部件是钢材质,可以直接焊接到我们之前做的广场管钢架上。整个框架是易毁的,为了增强耐久性要在外观大量镀膜。

There are also times when a client requires letters being cut from steel plate,not aluminum,and that is another place where a modern plasma table with shine.For letters that will weld to gates,or weld to steel entrances(as in over a park or cemetery)and to be cut from mild steel,or any letter application at all as long as the steel gets a high-quality powder coated finish in the end.

有时候客户会要求从钢板而不是铝中切割字,这是另一个等离子切割机发挥作用的地方。因为字母是从低碳钢里切割得到的,要焊接在门上,钢制入口(比如在公园或公墓的大门上),或者别的需要字母的地方,所以最后需要在钢板上大量镀高质量膜。

Such lettering can certainly be done with a CNC plasma cutting table,over a waterjet,with no noticeable loss of quality and much cheaper and faster. And fast may be the key word,as plasma cutting will average 5 to 10 times quicker than waterjet cutting on steel of the same thickness.

这种字体就应该用CNC等离子切割机来完成,而不是水切割机,因为没有明显的质量损失,更便宜,更快。速度是关键,切割同样厚度的钢板,等离子切割机比水切割机平均快5到10倍。

In years past I have made the mistake of having work cut on a waterjet,when the quality of a plasma cut would have been perfectly fine and at less than half the cutting cost.Or even wasting time making base plates or structural parts by hand, drilling them on a drill press and so forth,which is really a serious waste of time in light of how fast and accurate this work can be done on a good plasma table.

在过去的几年里,等离子切割技术已经发展的很好且价格低于水切割机的一半,而我却还在用水切割机。亲手做基础板和结构部件,用电钻打孔等等,真的是严重浪费时间的行为,因为一个好的等离子机器能够迅速精确的做这些工作。

So,when the type of work at hand means a router won't do it,and a waterjet is overkill,there is a large middle ground where the best tool for the job is going to be a modern CNC plasma table,and you can almost be certain there is one nearby and ready to be put to work, and it will likely save your company some money in the process.What's not to like about that?

因此,当你手头的工作用围字机做不了,又由于水切割机威力过大,这里就有一个巨大的价值空间,那就是现代数控等离子切割机,能够确定在附近有一台已经做好投入工作准备的数控等离子切割机,并且能在工作过程中为你的公司省钱。我们有什么理由不喜欢呢?