Improvements in CNC routing technologies over the past few years continue to open up profitable opportunities for savvy sign makers. New cutting tools and expanded software capabilities are now tailored specifically to cutting and trimming printed graphic signs on rigid as well as more flexible substrates and machining and carving three-dimensional signs and letters.

在过去的几年中CNC设备技术的改进,为内行的标识厂家不断开拓了有利的机会。新的切割工具和扩展的软件功能,大大提升了切割和裁切刚性图形标志、基板、三维标志的灵活性与操控性。

These new options also allow sign shops to their routers on softer substrates such as foam boards as well as denser substrates like acrylic, polycarbonate, PVC sheet, composite and layered composite substrates, and HDU solid-block substrates; all of which be can be used in a host of applications.

这些新的选择也为标识制作商家提供了在新的材料上操作的机会,在比较轻的材料像发泡板,还有一些比较厚的板材,如亚克力板,塑料板,PVC板,合成的复合材料板,HDU固体基板等等;这些在许多应用中都会用到。

Michelle M. White, technical applications manager at Vycom Plastics, Scranton, Pennsylvania, says that developments in CNC router technology over the past decade have definitely had a huge impact on the sign market and the jobs that shops can now produce.

Michelle M. White, 宾夕法尼亚州斯克兰顿Vycom 塑料的技术应用经理,说到:过去几十年的CNC切割技术的发展,对于标识市场和制作商家的工作都有一个很大的影响。

There are more routing product options out there than ever before with more precision finishing features such as knife cutting, laser cutting and routing all in one,” she comments.

她补充道:针对“切割机,激光机和围字机等等这一类的产品,现在的产品选择的种类是越来越多,并且比之前的加工机器精准度高”。

“This trend has led to faster CNC router cutting solutions being used to fabricate a wider variety of substrates with quicker turnaround times. Based on the feedback from some of the sign shops we work with, expanded foam PVC, polycarbonate, styrene and acrylic seem to be the most popular choices for projects as we move into 2016,” White adds.

“这种趋势已经加快了CNC切割围字应用,一般用在制造更多种类的板材上,周期时间更短。从一些我们合作的标识制作商的反馈上来看,PVC板,塑料板,复合材料板和亚克力板的范围扩大,随着2016的靠近,这些似乎在项目上是最受欢迎的选择,”White补充到。

More Rigid Options

严格的选择标准

Patrick Mikes, marketing coordinator at Denco Sales, a wholesale distributor based in Denver, adds that the most common substrates he is seeing being used are HDU, aluminum, brass, other metals, PVC, acrylic, engraving stock, polycarbonate, hard/soft woods and Avonite.

Patrick Mikes,Denco销售部的市场专员,总部设在丹佛的批发经销商,补充说到,他看到的正在应用的大部分基板材料都是HDU,铝合金,黄铜,还有一些非金属材料,PVC板、亚克力板,雕刻板,塑料,坚硬的或者软性的木材等。

These materials can be fully routed (routed through) or engraved (not routed through, but chiseled on the surface). A swivel tool can also be attached to the router, which gives the machine the ability to plot vinyl that is already mounted to a substrate. The vinyl is then weeded out. One of the products that many of our customers use is DUNA HDU, as it provides less dust and a cleaner cut when routed.”

这些材料可以完全用于切割或者雕刻。转轴设备也可以连接在切割机上,这样可以在基板上作业的时候判断材料是否到位。很多的客户钟情于DUNA团队的一款设备就是DUNA HDU,他们看重的一点是:操作更干净,切割更美观。

He points out that routers are most commonly used to make dimensional signs that show depth and perspective. He says that some common types of dimensional signage include: push-through signs, backlit signs, raised or recessed imagery, prismatic letters (beveled/peaked and contoured). Additionally, routers are used for model making, creating molds and press stencils, and ADA signage.

他还指出,围字机用的最常见的就是制作三维立体标识,能够展现标识的深度和透视度。他说常见的几种类型的立体标识包括有:推进式标识,背光式标识,凸式或凹式标识,柱状的标识字(斜面的/尖的和波状的)。另外,围字机也被用在制作模型,创造模具和挤压钢板,还有ADA标识上。

Still in the Designer's Hands

设计者是产品走向的最后决定者

Mikes explains that although there are more automated cutting options, it still comes down to designer's creativity and skill that ultimately determines the quality of the routed sign. “Most routers will give the designer the rough-cut (basic forms and layouts), but a lot of the finishing is still done by hand. No singular material is most popular or commonly used, as it is the combination of materials that makes up the sign. These materials are chosen based on a client's specifications or the designer's suggestions. For example, a designer that is creating a backlit sign could use a translucent colored acrylic for the base/background of the sign, and they could create a stark contrast by using metals or woods when creating the lettering/graphics in the forefront of the sign. Or, they could use aluminum for the background and raised plastic lettering in the forefront to make the sign pop dimensionally.”

Mike解释到,尽管现在有很多自动化的切割机选择,但是设计者的创新和技巧还是最终决定标识的质量的。“大部分的围字机会帮助设计者做一个粗糙的切割(基础形式或者设计格局),但是大部分的精细加工还是需要手工完成的。没有哪一种单一的材料是最受欢迎或者是用的最常见的,因为标识制作都需要几种材料的组合。这些材料的选择都是基于客户具体的要求或者设计者的建议。例如,设计者想要制作一个背光标识,就可能会用到一个半透明色的亚克力板作标识的基板,然后再用金属或者木材的字放在标识的表面,这样会形成一个鲜明的对比。或者,也会用铝合金作底板,然后突出来的塑料字做标识的表面,这样也能让标识看起来有立体感。”

Layered Options

多层选择

Mikes says a variety of different materials can be used for just one sign, as numerous layers can exist in the sign's layout. “There are so many combinations of materials that determine the overall graphical style of the sign. The most common projects include architectural dimensional signs, retail/storefront signs, corporate signage, way-finding and directional signage, ADA signage, ornate furniture, decorative interior art, and municipal signage,” he adds.

Mike说到大量不同的材料可能只用在一个标识上,因为标识布局上可能会存在很多层。“这么多材料的组合就决定了标识外观的整体风格。最常见的项目包括有建筑空间标识,零售/店铺标识,企业标识,导向标识,ADA标识,华丽家具上,室内装饰艺术中,市政府标识,”他补充到。

HDU Signage Options

HDU 标识选择

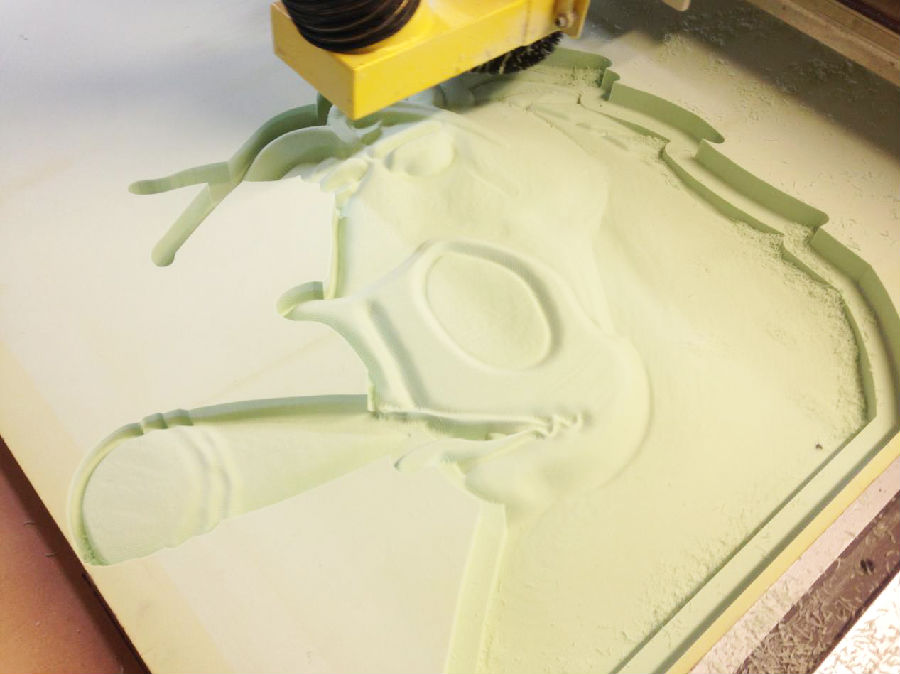

Brad Burnett, HDU sales rep at DUNA-USA Inc., Baytown, Texas, says one of the latest trends he is seeing is their HDU product being incorporated into exterior, lighted signage. “Because HDU can be intricately fabricated into unique dimensional backgrounds and designs, it can be used quite effectively to create cost-effective, high-end signage.”

Brad Burnett, DUNA-USA 公司的销售代表, 贝城,德克萨斯州, 说他现在看到的最新的一个趋势就是,他们的HDU产品正在逐渐应用到外部发光标识上。“因为HDU可以在制作独特的空间标识设计时,进行精细的制作,这样就会大大加快低成本,高收入的标识的制作。”

He points out that HDU has typically been the substrate of choice for businesses offering CNC routed signs, mainly due to the fact that it has no grain and is non-abrasive.

他指出,HDU已经很明显成为了商业上制作CNC围字标识材料的选择,这主要还是由于HDU材料没有纹理以及不粗糙。

“It's not going to wear a cutting bit down like wood or metal will, and is extremely versatile in regards to design capabilities,” he says. “It's not uncommon to see an exterior, lighted sign, crafted from a combination of MDF, HDU and aluminum. The HDU allows for a high-degree of dimensional customization, while the MDF and aluminum are typically used in reinforcing roles.”

“这种材料也不会像木材或者金属那样磨损切口,而且在设计能力方面也是通用型的,”他说。“由MDF,HDU和铝合金组成的精心制造的外部发光标识也不是不常见。HDU在尺寸上是可以任意规划的,同时MDF和铝合金起着加强固定的作用。”

Burnett reports that HDU is most often used to give a sign a dimensional look.

Burnett报道,HDU用的最多的就是在创造立体标识外观上。

“Another common application is to be used as dimensional letters, which are often added to a flat background made from HDU or another substrate such as wood or metal,” he says.

“另外一个常见的应用就是用作空间立体字,经常是被放在平板底板上的,这些底板是由HDU或者另外一种材料例如木材或金属组成的,”他说到。

Burnett adds that many types of signs can incorporate HDU into them to add a visually pleasing dimensional look: Monument signs, channel letters, fascia signs, hanging signs, address plaques, and even golf course signage. “It's also popular for HDU to be used as a ‘master mold’ to create vacuum-formed sign faces. Our newest product is the DUNABOND line of HDU adhesives. The single-part, polyurethane adhesives are both waterproof and can be used to bond HDU, wood, metal, concrete, and other expanded materials together.”

Burnett补充到,很多类型的标识都可以把HDU应用到上面,来增加三维立体空间的视觉效果:纪念碑标识,发光字,标识标牌,悬挂标识,导向标识,还有高尔夫路线标识。“HDU用作顶级的模型也是很受欢迎的,能够创造真空的标识外观效果。我们最新的产品是HDU粘合剂DUNABOND系列。有一个特点,聚氨酯粘合剂既能防水,又能把HDU,木材,金属,混凝土和其他发泡材料粘合在一起。”

Standing out From the Crowd

做最优秀的生产商

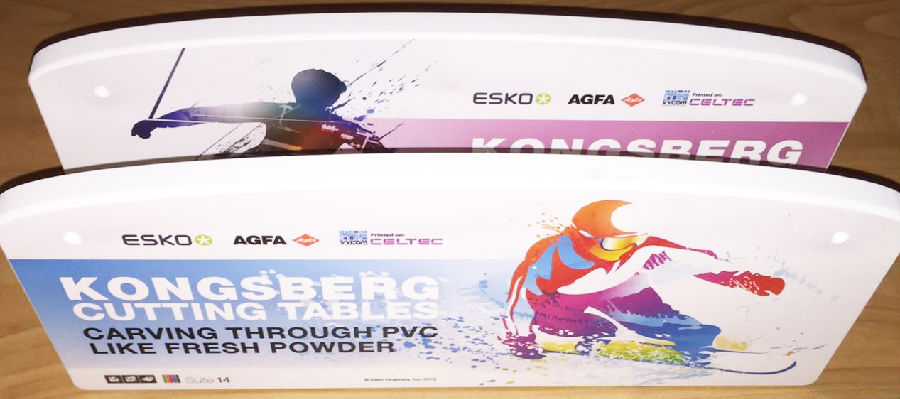

Brandon Wyatt, marketing manager,3A Composites USA, Statesville, North Carolina, reports that more and more retailers are focused on differentiating their brand through intricately designed signs and graphic displays.“To create these unique looks, designers and fabricators continue to turn to lines of rigid substrates that have trusted reputations for producing clean, quality cuts with CNC routers, including: our heavy-duty Gatorfoam foam-centered board, Sintra PVC board and Dibond aluminum composite material.”

Brandon Wyatt,美国3A复合材料的市场经理,斯泰茨维尔,北卡罗莱纳州,报道说,越来越多的零售商家注重区分自己的品牌,通过精心的设计标识和展示。“为了创造独一无二的外观,设计者和制作者会倾向于使用刚性板材,这些板材在CNC围字机高质量,整洁的切割上都享誉盛名,包括:我们的重型Gatorfoam 泡沫板,Sintra PVC板和Dibond铝合金复合材料。”

He explains that heavy-duty Gatorfoam foam-centered board; Sintra PVC board and Dibond aluminum composite material remain popular with fabricators who rely on these durable, rigid substrates because they are well suited for clean routing. “These three rigid substrates offer fabricators a range of price points and physical characteristics designed to meet varying customer needs for the length of time as well as the location that signs will be displayed.”

他解释到,重型Gatorfoam 泡沫板,Sintra PVC板和Dibond铝合金复合材料还是很受制作者欢迎的,这些制作者都是比较信任这些耐久性好的刚性板材,因为这些都适合整洁的切割围字。“这三种刚性材料给制作家提供了一系列的价格层次和物理特性,能够满足不同客户对于时间长短,标识展示的位置等类似的需求。”

“Dibond aluminum composite material offers the greatest durability in creating permanent exterior storefront signage. Sintra (in the 6mm and greater thicknesses in the Bright White, Black, Gray and Light Gray colors) also may be used to create exterior signage. Additionally, Gatorfoam (in the 1 inch and greater thicknesses) may be used outdoors provided that the board’s edges are painted to protect the sign from UV exposure.”

Dihond铝合金复合材料在店铺外部标识的持久性上是最好的。Sintra(有6mm的,厚一点的,雪白色,黑色,灰色,浅灰色)也是用在外部标识上的。另外,Gatorfoam(有1英寸的,还有厚一点的)可以用在户外标识,主要在板的边缘上油漆,来保护标识不被紫外线曝光侵蚀。

Smart Products from 3A Composites

3A复合智能产品

Wyatt says that 3A's SMART-X and KAPA tech products are two new easy-to-route rigid premium substrates originally introduced by 3A Composites in Europe and were recently rolled out in the United States.

Wyatt说,3A的SMART-X and KAPA 技术产品是两种新的易切割的刚性优质板材,最初是由欧洲3A复合材料公司引进的,最近才被推出到美国。

“SMART-X is a premium quality distinctive lightweight foam board consisting of an all-plastic sheet that is uniquely constructed with a moisture-resistant expanded polystyrene core and two layers of UV-resistant solid polystyrene. SMART-X can be installed outdoors without experiencing any significant change in color for a period of up to two years. It can be direct-digital printed and is easily routed and milled for sign and displays.”

“SMART-X 是一种优质独特的很轻的发泡板,全部是由塑料板材组成的,这些都是独特的由防潮发泡材料和2层防紫外线固体聚苯乙烯组成的。SMART-X 也可以安装在户外标识上,一到两年的时间都不会褪色。而且标识和展览方面也可以直接数字印刷,又容易切割碾压”

He says that KAPA tech is a hybrid graphic display board that combines the lightweight characteristics of a foam board with the durability of an aluminum composite material—two pre-painted sheets of .008-inch aluminum bonded to a polyurethane foam core.

他说,KAPA技术是一种混合的标识展示板材,结合了发泡板重量轻,铝合金复合材料耐久的特性-由两块油漆好的0.008英寸的铝合金板材贴附到一整块泡沫板上。

“This hybrid construction allows KAPA tech to perform in both indoor and outdoor graphic displays with the durability of an aluminum composite material (ACM) but at half the weight of an ACM,” he adds.

“这种复合的结构使得KAPA科技能够在室内和户外的展示都可以用,拥有铝合金复合材料的耐久性,但却只有铝合金复合材料一半的重量,”他补充到。

Shop Applications

企业应用

Vycom's White reports that many of their end users are doing some wonderful things with their products and points that one shop in particular that is doing some interesting work in this area is NGS Printing based in Elgin, Illinois.

Vycom's White 报道,他们很多终端客户都在他们的产品方面做一些比较有趣的工作,指出:有家店铺,特别是在这个区域做一些有趣的事情的,就是NGS Printing,坐落在埃尔金,伊利诺斯州。

“They are using many of our products, including expanded PVC, to decorate a variety of items such P.O.P. displays, video games, pinball machines, kiosks, wire displays as well as a variety of other industrial uses,” she explains.

“他们现在用的很多产品都是我们的,包括PVC发泡板,用来装饰一系列的物品,例如POP展览展示,电子游戏,钉球机,报亭,金属展具,还有一系列的工业用途,”她解释到。

“We find that expanded PVC is a very economical substrate for many P.O.P. applications and is used extensively atNGS Printing for a variety of components and signage,” comments Mark Landrowski, VP of operations. “Our new state of the art digital print equipment offers the option to print directly onto a wide range of surfaces and media. Our digital solutions are the perfect answer to our client’s short-run, quick turn or prototype needs,” he adds.

“我们发现PVC发泡板在很多P.O.P.应用中都是很有经济价值的板材,在NGS Printing的标识组件中应用的很广泛,”Mark Landrowski补充到,运营副总裁。“我们现有的数码打印设备提供了很多选择,可以直接在很多材料表面和介质上打印。我们的数码打印解决方案,在客户短期运转,快速运转或者模型需要方面都是很完美的解决方案,”他补充到。

House of Signs

标识之家

Frisco, Colorado-based House of Signs specializes in custom-routed and handcrafted 3D signs and unique support structures. They have been designing and fabricating award-winning creations since 1989.

弗里斯科,科罗拉多州的标识之家,是专业从事定做围字和手工3D标识以及独特的建筑设计标识的。从1989年开始,他们一直从事设计和制作加工一等的标识作品。

“The CNC machine is one of our favorite tools, and offers such a diverse number capabilities. We just finished installing a new Multi-Cam 3000 with auto tool-changer. This is the Rolls Royce of CNC machines, and we are very excited to push the limits this year and beyond,” states Roger Cox, founder and president.

“CNC设备是我们最喜欢的工具之一,能够提供多样化的功能。我们刚刚用自动切割机器完成一个新的Multi-Cam 3000的安装。这台是Rolls Royce CNC机器,我们今年很高兴又进一步扩大了我们的市场。”Roger Cox创始人兼总裁说到。

He reports that the most common substrate they use for milling 3D signs is CoraFoam by DUNA-USA.“After product-testing many high-density urethanes over the years, we have found the quality of CoraFoam to be at the top of our list. Very tight-celled and smooth, this product holds incredible detail while remaining very strong, and doesn’t absorb primers and paints like some other HDU products we have worked with in the past. We normally mill a rigid backer for all our signs using ¾-inch MDO plywood. The CNC handles this dense product with ease,” he adds.

他还报道过,他们现在用的比较常见的用来制作3D标识的基板就是DUNA-USA的CoraFoam。“经过了这些年的高密度的产品测试,我们发现CoraFoam质量在我们的物品中是最好的。有着比较细密和光滑的特点,这种产品有着令人难以置信的特点同时又是非常坚硬的,也不会像我们过去的HDU产品那样会吸附小分子和油漆。我们做所有标识一般都是用3/4英寸的MDO胶合板来做坚硬的底板。CNC机器处理这种精密的产品毫不费力,”他说到。

PhotoWorksGroup

图像解决方案

PhotoWorksGroup, Inc., a large-format graphic solutions provider based in Charlottesville, Virginia, has been creating large-format graphics, exhibits, displays and signs for museums, universities, health care institutions, manufacturers and corporations since 1986.

PhotoWorksGroup公司,一家宽幅平板打印方案提供公司,位于弗吉尼亚州,夏洛茨维尔,从1986年开始,一直专注于创造宽幅平板打印,展馆,大学,医疗中心,制造商,合作商的展架,展具,标识。

While PhotoWorksGroup uses all types of media, including fabric and vinyl, Geoff Kilmer, president, PhotoWorksGroup, estimates that three out of every four of the company's projects are produced with rigid substrates. To meet the individual needs of each project, Kilmer frequently turns to the wide array of rigid substrates offered by 3A Composites USA.

PhotoWorksGroup 可以用各种介质打印,包括织物,乙烯基板,Geoff Kilmer,PhotoWorksGroup 的总裁,估计公司项目的3/4都是用刚性板材生产的。为了满足每一个项目的需求,Kilmer经常会向3A美国复合材料公司进购大量的刚性板材。

“With the addition of our Zünd digital cutter, working with rigid substrates is more efficient than ever. The most common rigid substrate we use is Sintra. It's suitable for a wide gamut of applications, is dimensionally stable, and cost effective. We enjoy being able to gang print to large sheets, then cut out on the digital cutter. It really cuts down the labor cost enabling us to remain competitive and profitable,” Kilmer explains.

“有了我们的Zund数字切割机,在硬性板材上作业就比以前更加有效率了。我们用的最常见的刚性板材就是Sintra.它适合各个范围的应用,尺寸稳定,成本高效。我们喜欢在大的板材上批量打印,然后在数字切割机上裁切。这样确实能够节省人工成本,我们的产品也就具有竞争力还有比较可观的利润,”Kilmer解释到。

“In today's competitive market, you really need some automation such as a digital cutter, to cut down on labor costs. I would rather purchase the premium materials such as Sintra, to insure the client gets the best quality product, and save production costs through good organization, production techniques, and automation. As digital cutters become the norm, I believe it is becoming harder and harder to operate competitively in today's market without one,” he concludes.

“在市场竞争激烈的今天,我们是真的需要一些自动化的设备例如数字切割机,来削减人工成本。我宁愿购买优质的材料例如Sintra,这样能确保客户得到的产品质量是最好的,也能通过好的组织,产品技术和自动化设备来节省产品的成本。随着数字切割机变得越来越普遍,我觉得,在今天这样的市场中,没有一台这样的设备,想要制作出具有竞争力的产品是越来越难的,”他总结到。