Like any machine in your shop, the best way to make sure your laser engraver is generating a profit is to keep it running full time. The best way to do that is to make sure you are getting the most out of your machine to offer your clients exactly what today's customers demand. We asked some laser engraving companies about what they are seeing in terms of hot trends and profitable applications.

就像标识店铺里的很多机器一样,要确保激光雕刻机能够一直盈利,最好的方法就是要让它能一直运行。要做到这点,最好就是充分利用机器的运行,能保证满足客户每时每刻的需求。我们也问过一些激光雕刻公司,哪些是激光雕刻的热门和利润可观的应用领域。

What are the hottest trends that require the use of a laser engraver?

激光雕刻机应用的最新的潮流趋势是什么?

•“Laser cutting/engraving systems are exceptionally versatile, so it's interesting to see new and exciting ways our technology is being used,”says James Stanaway, director of marketing,Epilog Laser.“Signage is a huge market for Epilog; however, we're seeing an uptick in a variety of areas including paper/invitations/crafts as well as fabric and textile cutting/engraving. Because you can dial down the settings so precisely with a laser you can cut/engrave incredibly detailed and ornate designs from very delicate materials like paper and fabric.”

·“激光雕刻和切割系统几乎是万能的,所以我们能看到一些技术应用的新奇方式,”Epilog 激光设备公司的市场主管,詹姆斯Stanaway说到。“对于Epilog来说,标识是一个巨大的市场;然而,我们现在正在见证各个领域的发展,包括纸,邀请函和工艺品以及织物和纺织品切割/雕刻。因为可以调整,精确激光机的设置,这样就能用非常精细材料例如纸张和织物,做出精美华丽的设计作品。”

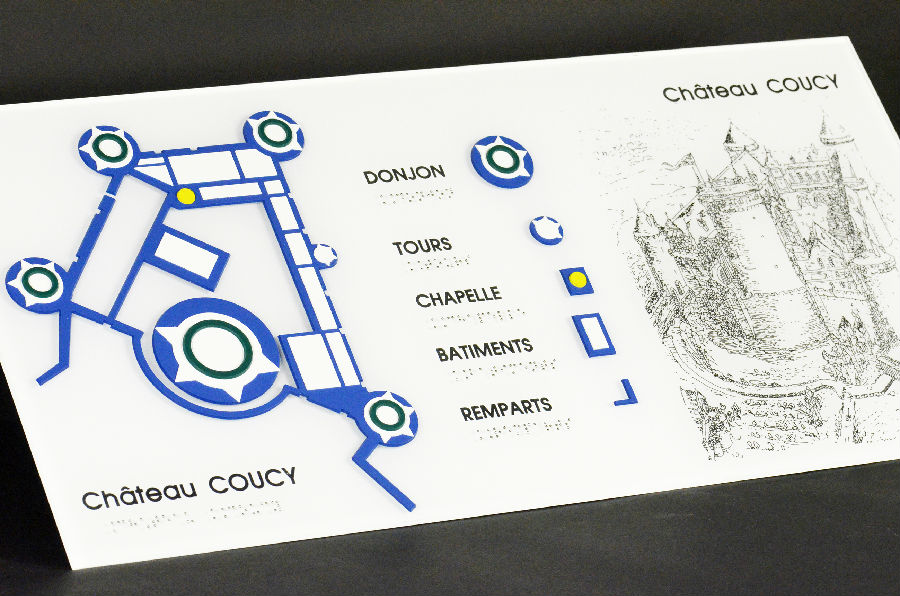

•“Some of the latest trends in laser marking include dimensional sign cutting and ADA and wayfinding applications,”says Anthony Harris, application specialist for Gravograph.“Precision cutting, with the added benefit of a flame-polished edge, opens up the ability to produce inlay elements and decorative effects not accomplished by any other technology.

·“激光市场里面最新的趋势也包括了空间标识切割,和ADA以及导向应用方面,”刻宝公司应用专家,哈里斯·安东尼说到。“精密打印,加上抛光面的优势,能够完成一些其他技术不能完成的,比如镶嵌和装饰的一些方面。”

“Certain software systems, like Gravostyle, you can design a job layout for your laser that can also drive the router table's braille process. This improves workflow efficiency, reduces the software learning curve and provides consistent job registration between machine technologies.”

“有些软件系统,像Gravostyle,就可以在激光操作时做布局设计,还能处理盲文操作。这样既提高了工作效率,也减少了软件学习的弯道,同时也保证了操作技术工作的一致协调性。”

•“Creating customized signage through a combination of digital printing and laser technology is very popular,” says Josh Stephens, business development,Trotec Laser. “Many retailers are making acrylic signs that are back lit, which would require a lot of post processing without a laser. ADA compliant signs are another very popular laser application.”

·卓泰克激光雕刻公司运营部乔什 史蒂芬说到,“通过数码印刷和激光技术的结合,创造个性定制化的标识非常流行。”“很多零售店铺都在制作亚克力标识,背光发光标识,要是没有激光机的话就需要很多后期处理。ADA标识又是激光雕刻领域另外一个比较流行的。”

What are some highly profitable applications for engravers?

雕刻机的一些高利润的应用领域有哪些?

•“ADA signage, industrial tags and rating plates and point of purchase display fabrication,” Harris says.

·“ADA标识,工业标签和标牌以及一些服装展示柜台,”哈里斯说到。

•“Customers are encouraged to laser cut preprinted materials (laminates, acrylic, plastics, paper, wood, etc.) Stephens says.“This can yield high profit margins because a laser can create custom signage, displays, stationery, and more with unique shapes and sizes that will appeal to any customer.”

·史蒂芬说到,“要鼓励客户使用各种材质的材料进行激光雕刻(像分层板,亚克力板,塑料,纸,木材等等),这样就能有高利润空间,因为激光雕刻机可以做个性定制的标识,展览展示陈列道具等,以及能够吸引客户的一些独特形状和规格的图形图像。”

•“Electronics customization is a higher-return application,” Stanaway says.“Since the product is customer-supplied, there are no material costs for this type of project. Additionally, due to the expensive and high-end nature of electronic devices, people are willing to pay a premium to make their mass-produced phone, tablet or computer really stand out.

·“电子产品定制化是一个高收益的应用,”Stanaway 说到。“因为这种类型的项目中产品是客户提供的,也没有什么其他材料损耗。另外,由于电子设备的昂贵和高端的性质,人们通常会愿意支付额外的费用,这样他们的大量生产的手机,平板电脑,笔记本电脑都能够引起人们的关注。”

“Another high-profit margin application is photo engraving. Engraving a photograph gives it that‘forever’feel. Over time, photos can get lost or damaged – engraving them onto a beautiful wood or marble plaque allows customers to capture a very specific moment in time forever.”

“另外一项高收益的应用就是图像雕刻。雕刻图像能够帮助长久的保存下来。随着时间的推移,照片可能会遗失或者损坏—把图像雕刻在精致的木材或者大理石牌匾上,这种方式可以帮助客户永久的保存图像。”

What specialty products are you seeing your customers create?

客户创造的一些特色产品是什么?

•“Our customers are creating various custom cut, engraved and digitally printed awards, signage and promotional items,”Stephens says.“The possibilities of customization with a laser are endless because of the ability to integrate with other technologies, the vast array of materials that can be processed, and the ease and speed they can be processed with.”

·“我们的客户会创造各种各样的定制化的切割,雕刻和数码印刷标牌,标识和促销产品,”斯蒂芬说到。“激光雕刻机定制化的可能性是无限的,因为它结合了其他的一些技术,有大量可以处理应用的材料,操作速度也很快。”

•“We have a fan group on Facebook, the Epilog Laser Fans, and from that group of 5,000-plus members we see a great variety of new products and projects,”Stanaway says. “Particularly popular right now are laser-cut (hand assembled) corn-hole game sets with laser-etched bean bags for throwing; laser-etched stainless steel tumblers; and personalized map engravings.”

·“我们在Facebook上有一个粉丝群,Epilog激光群,从这个5000多位成员的群里,我们可以看到各种各样的新产品和项目,”Stanaway说。“现在特别流行的就是激光切割(手组装)玉米洞游戏,投掷激光雕刻的豆袋;激光雕刻不锈钢玻璃杯;个性化地图雕刻。”

•“With oversized machines with generous pass-through capabilities, customers are finding interesting niche applications such as lasering wooden doors, cabinets and decorative screens quite profitable,”Harris says.

·哈里斯说到,“有了大号的设备和大容量的传输量,客户就开始寻找一些利润可观的,有趣的日常应用,例如激光雕刻木门,橱柜和一些装饰性的屏风。”

What are some newer or trending applications that may require shops to upgrade their laser power or increase their table size from their current engraver?

有哪些新型的应用领域是需要商家升级激光设备功率或者操作机床规格的?

•“Your laser may need to be upgraded to a higher power or larger table size when you are processing items like Corian, glass, marble, wood and specialized composite materials like 3-Form," Harris says. "The need for higher power is especially evident when processing thick substrates like 1” acrylic with polished edges."

·“当处理这些材料时,像可丽耐,玻璃,大理石,木材和特殊的复合板3-Form,激光雕刻机可能就需要升级到更高一点的功率或者大一点的操作机床。”哈里斯说到。“在处理厚基板时,像1” 抛光亚克力板,高功率的要求就比较明显了”

•“We are seeing many sign shops that want to expand their product offerings and engraving/cutting capabilities on different mediums," Stanaway says.

"While CO2 laser engraving/cutting systems are ideal for more organic materials like wood, stone and acrylic, they were not designed to tackle bare-metal marking applications that are more industrial in nature. These types of applications are better addressed by a fiber laser system.

·“我们看到很多标识店铺都想要扩展他们产品供应种类,以及不同材料上的激光雕刻能力,”Stanaway说到。“虽然二氧化碳切割雕刻设备非常适合有机材料,如木材,石头,亚克力板,但是他们的目的不是为了裸金属操作对准应用,这项应用实质上是比较工业化的。这种类型的应用用光纤激光系统操作会更好。”

Epilog recently launched the Fusion M2 Laser Series, which features the Fusion M2 32 and Fusion M2 40, two systems with dual-source laser capabilities that can perform all kinds of applications on nearly any material. The systems in this series are available with both CO2 and fiber laser sources within the same cabinet. This allows designers and manufacturers to use one piece of equipment for two very different applications much more seamlessly and in a smaller area.

Epilog最近推出Fusion M2系列,结合了Fusion M2 32和Fusion M2 40的特点,配有两种双源激光系统,几乎能在所有材料上处理各种应用。这系列的系统可以应用在同一橱柜上,二氧化碳和光纤激光源都可以。这样设计者和生产厂商在用一种设备做两种不同产品时,能在小的空间里贴合的更加完美。

This cutting-edge laser series also includes exceptionally precise camera recognition capabilities that allow users to quickly and easily cut pre-printed graphics from cardstock, acrylic and nearly any other medium. The eView Camera Module has been exceptionally well-received by the signage community in particular.

这款先进的激光设备还具有异常精准的图像识别功能,以便于客户能够在纸片,亚克力板和其他的介质上,快速轻便的切割预打印的图像。友好的电子触摸屏现在已经很受欢迎了,特别是在标识行业。

"The eView makes cutting printed graphics incredibly easy and produces exceptionally precise results from anywhere on the table. There's no need to line up your graphics to the top-left corner of the machine, or even to align it to the x and y-axes-users simply add registration marks to their graphic and the cameras detect exactly where to cut.

触摸屏可以让切割图像变得更容易,不管在任何操作机床上都能有精确的结果。图形图像不用排队输送到设备左上角,或者按照坐标轴线来规划,只要简单的对准图像,这台触摸相机就可以准确的把握切割点。

"After users have placed their graphics on the table, Epilog’s Job Manager shows a real-time photo representation of the laser table with the printed graphic and its true position on the table. From the Job Manager, operators click the registration marks they want to use, and the eView Camera software does the rest.”

“用户把图像放在操作台后,Epilog的市场经理就就给我们展示了一个激光操作台的实时的图像,图像和位置都已准备好。之后,操作人员点击操作按钮,接下来的工作就交给触摸相机操作了。”

•“In the signage industry multi-material signs are making customers consider upgrading their machines,”Stephens says.“For example: A customer may upgrade to a dual-source laser if they wish to create products with an organic material and metal. A dual-source machine allows for cutting, engraving and marking. In order to create larger signs, customers are also upgrading to larger format machines with pass through capabilities. Finally, many engraving shops are adding vision systems to their existing machines to ensure accuracy and increase production with preprinted materials.”

·“标识行业内出现的多元化材料使得很多客户都想升级设备,”史蒂芬说到。“例如,如果想要用有机材料和金属制作一些产品,客户通常就会升级双源激光设备。双源激光设备可以切割,雕刻和标记。为了制作一些大型的标识,客户也可能会考虑换一台具备路径功能的大型打印机。最后,还有很多雕刻标识商家会在现有的设备上增加可视化系统,这样可以确保精确度,提高生产率。”

Is there a big difference in what shops should be looking for in a laser engraver if they want to do more cutting than etching?

如果你希望切割与雕刻作出对比,那么在激光雕刻设备需求方面有什么不同吗?

•“When it comes to cutting, wattage is the most important factor,”Stephens says.“The general rule for optimal cutting speeds and quality is for every 1/8" of material, 30W is needed. Ventilation is the second most important variable. With the right power and speed settings, it's simple to achieve perfect flame polished edges with zero post processing.”

·“谈到切割,功率是最关键的因素,”史蒂芬说到。“最理想的切割速率和质量就是每种材料1/8’’,30W。通风设备是其次。有了合适的功率和速率设置,想要实现完美的火焰抛光边缘处理以及后期精细加工的处理,就很容易了。”

•“Accuracy of optical registration when cutting printed media, insuring the program compensates for scaling, stretch, skew and rotation,”Harris says.“For heavy cutting applications efficient exhausting and an accurate finned cutting table are essential for consistency.”

·“切割打印介质的时候,光对准的精确度能够保证程序能够把握缩放,拉伸,倾斜和旋转,”哈里斯说。“对于深度切割应用来说,有效的排气和精确的切割台凹槽都是至关重要的。”

•“Higher-wattage options,”Stanaway says.“Having a higher wattage laser (75 -120 watts) allow our users to both cut through thicker materials – up to about ½”of hardwood or acrylic – as well as engrave/etch faster than lower-wattage machines.If sign shops are looking for higher production values, a larger format, high-wattage machine is definitely the way to go.”

·Stanaway说道:“高功率激光设备(75-120瓦)可以同时切割比较厚的基板材料-上到½”硬木材或者亚克力板-雕刻也比低功率的设备速度快。如果标识店铺想要高品质的,肯定就要换大幅面,高功率的设备机器。”