When it comes to customized and personalized apparel, we've come a long way from the days of those T-shirt shops some of you may remember, filled up with Pac-Man machines.

谈到定制和个性化服装,我们经历了漫长的过程,你们印象中的一些T恤商家都是用烫画机制作服装的。

Back then, technology was very simple – you picked your favorite from a wall of pre-made images or selected a series of letters, and using heat-activated plastic transfer, they'd be happy to hot-press Farrah Fawcett or your name onto a shirt of your choice. Unless you had the time or patience for traditional screen printing, that rubbery iron-on was about as custom as you got.

最初的喷印技术是很简单的———你选择一张最喜欢的图片或者一系列字母,然后在衬衣上用热转印纸就可以把图片或字母热压成法拉·福赛特或你的名字。如果你对传统丝网喷印技术没有足够的耐心,那么你定做的服装就是把橡胶状的东西黏附于衬衣表面上。

Customers nowadays are seeking more sophisticated and truly personalized options. With the continuing evolution of digital technology, print and sign professionals can – with the right equipment – set themselves up to offer bright, clean, long-lasting images on virtually any piece of clothing. Hats, shirts or even shoes are all potential canvases.

如今的消费者热衷于更加复杂和真正个性化的选择。随着数码技术的不断发展,使用合适设备的喷印和标识专家,可以在任何布料上呈现出明亮、干净、持久的图案。帽子、衬衣甚至是鞋子都是可用的材料。

For those looking to expand their sign business, new and sophisticated direct-to-garment printing systems can tantalize customers with wearable versions of their own logos, images or art, easily and affordably printed on as little as one item at a time.

对于那些希望扩大标识贸易的公司,新型复杂的服装喷印系统会让顾客等得很焦急,因为它每次只能喷印一个可穿戴的标识、图案或者艺术品。

Modern print shops looking for truly long-lasting images and greater flexibility have two major choices to consider: The more complicated dye sublimation process, which works only with polyester fabrics, or the relatively new and increasingly flexible direct-to-garment printing process, which finally allows bright, long-lasting images to be printed directly onto cotton or other garments.

寻求耐久性图案和灵活性更好的现代喷印设备,商家只需要了解:无论是使用涤纶染料升华的复杂过程,还是全新灵活的服饰直接喷墨打印过程,最后都会在棉布或其他布料上喷印出明亮的、耐久性的图案。

Direct-to-garment printers also offer more value than the slightly lower-tech digital transfers, the latest generation of the old-fashioned plastic transfer – specialized paper that can be run through a color printer or even printed at home, then heat-transferred onto an item of clothing.

老式的热转印机都需要转印纸,其工作原理都是用彩色打印机甚至家用打印机把纸张先打印好,然后经过热传递技术喷印到布料上。因此,服饰直接喷墨打印机比它们有更高的价值。

Matthew Rhome, head of business development for Epson America, Inc.'s fabric imaging division, says digital transfers have major shortcomings in durability, just like those old, fast-fading T-shirts.“As well, digital transfers still need to be cut out from the backing material, so artwork that includes fades or gradients are not possible,”he says.

美国爱普生公司织物成像部门的业务发展主管,马修·罗姆谈到:“数码烫画机很不耐用,就像那些旧的不耐穿的T恤一样。同时,数码烫画机如果要避免产生褪色问题,那就要停止使用基底材料。”

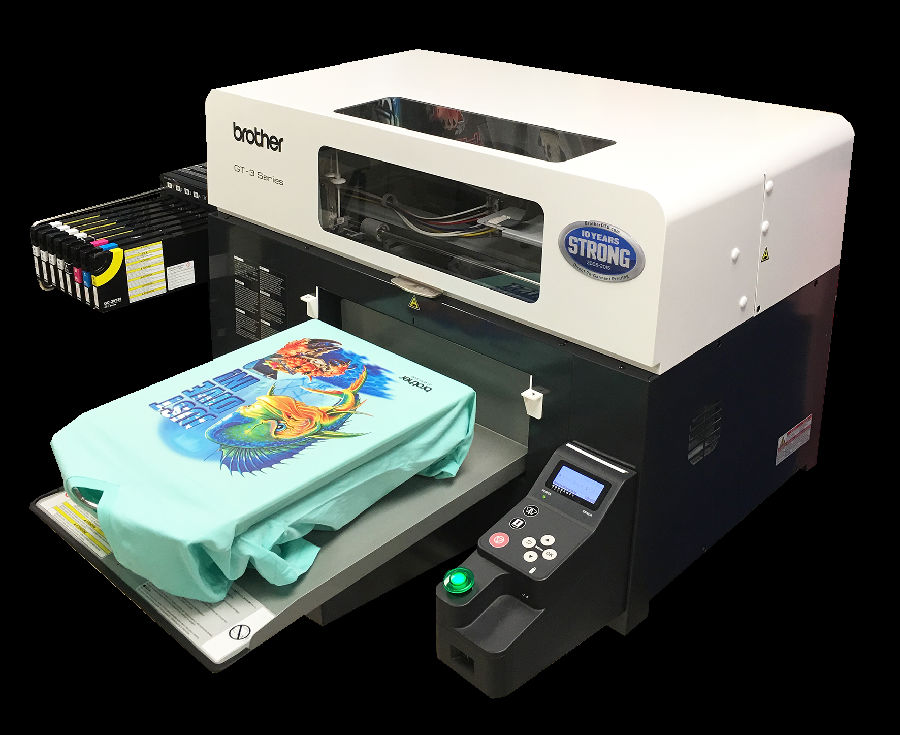

Mark Bagley, director of marketing for Brother International Corporation’s industrial products division, says that while the dye sublimation process has been a great way to create very colorful images on sport-related apparel (think cyclists' jerseys, as a vivid example), new digital, water-based-ink DTG systems offer many more choices and can also allow printing professionals the ability to do a simple one-off project for a potential customer, as a possible gateway to more business.

Brother跨国公司工业产品部门的市场主管,马克·巴格利说,目前染料升华技术已经可以在运动服装上喷印出色彩鲜明的图案(就像骑行者的运动衣一样),那么新型数码、水性油墨式服饰直接喷墨打印系统,就可以为客户提供更加专业化的喷印技术,这也是公司扩大贸易的一种途径。

“DTG works much better on natural, open-pore cotton materials, and can even be used on natural fibers like bamboo,”he says. “It's kind of like four-color CMYK printing on steroids, with a bigger print head and special ink that binds directly to the material.”

马克·巴格利说:“服饰直接喷墨打印机更适合在自然透气的棉布或天然纤维上工作。它是带有较大喷头,并且使用特殊油墨的机器。”

Rhome notes that the first commercially available DTG printer was introduced in 1996, but it was literally a CMYK-only model and had no capability for printing on dark garments. Many companies also experimented with equipment jury-rigged together from existing printer components, but the results were often less than impressive.

罗姆指出,第一台商用服饰直接喷墨打印机在1996年被引进,但是它只有CMYK一种模式,并且不能在深色布料上喷印。许多公司也曾尝试,用现有的打印机组件改装升级成新的设备,但是结果总是不尽人意。

“Since the introduction of this first printer, the most major advancement in DTG technology has been the introduction of reliable white ink and with it, the ability to print dark garments,”he says.

罗姆说道:“自第一台服饰直接喷墨打印机问世以来,最重要的改进就是,服饰直接喷墨打印技术可以用白色油墨打印深色布料了。”

Titanium dioxide-based white ink was introduced in 2005 but early formulation problems caused it to frequently clog printer components, leading them to wear out prematurely, Rhome explains. Current technology, introduced by companies that develop both the ink and manufacture the print heads, has cured most of those problems and lessened the need for maintenance.

罗姆解释说,2005年生产出白色二氧化钛油墨,但是早期的技术总是阻塞打印机部件运行,造成服装不耐穿的后果。目前既生产油墨又制造喷头的公司,已经解决了那些问题,并且减少了不必要的维护。

“Just like digital signage, the DTG printer can be used for one shirt or many at the same material cost per item,”he says. “A sign shop should understand that every sign customer is a potential DTG T-shirt customer. You already have the customer's art or design, so why not print shirts, too?”

罗姆说:“就像数码标识一样,服饰直接喷墨打印机可以用来打印一件或多件衬衣,标识店铺应该明白,每一个标识客户都是潜在的服饰直接喷墨打印客户。你已经得到了客户的艺术品或设计,那么为何不进行服装喷印呢?”

The DTG process is a bit more complicated than the old iron-on world, but the results are definitely worth it. Clothing items need to be pre-treated with a small dose of a spray-on solution that helps to better bind the ink to the fabric. After the shirt or bag is run through the printer, the item then also has to be cured with an adjustable heat press to seal in the image.

服饰直接喷墨打印过程比旧的烫印技术稍复杂一点,但是最后的成果是值得的。布料需要用少量喷涂方式做预处理,这样能够更好地把油墨浸入织物中。在衬衣或面料放入打印机后,还要用可调节的热压方式加工处理,把油墨密封在图案中。

Unlike the more extensive equipment required for the dye sublimation process, sign shops can begin their DTG work on a small and affordable scale, with prices for equipment dropping as the technology improves.

和多数设备所需要的染料升华过程不一样的是,随着技术不断提高、设备价格下降的发展趋势,标识店铺可以在小型可负担得起的规模下,开展服饰直接喷墨打印工作。

“With current promotions, someone could get started in the DTG business with an Epson F2000 white edition, a good heat press and a simple pretreating system for less than $16,500,”Rhome says.“Space requirements are very minimal – one could easily run the printing operation in an area not much larger than their kitchen table.

罗姆说:“就目前的发展而言,使用高敏热压和预处理系统的爱普生F2000白色版本设备,开展服饰直接喷墨打印项目,花费不到16500美元,并且对空间规模的需求是极小的——比厨房操作台稍大点的打印操作的区域就足够进行作业了。”

Ventilation isn't required and workflow is very straightforward – the shirt is pre-treated, then it is printed, and finally it is dried.”

罗姆说:“通风设备是没有必要的,服饰直接喷墨打印工作流程是很简单的——衬衣经过预处理,接着被打印,最后被风干就可以了。”

Flexibility is DTG's greatest asset, as sign professionals can use the equipment to offer a whole new range of printed products to their customers, but not necessarily have to commit to a major print order with an outside vendor. Costs are simply contained to the price of the printed object and supplies.

灵活性是服饰直接喷墨打印技术最大的优点,因为标识专家可以用这些打印设备,为客户做出全新产品,不需要给外部供应商提交打印订单,并且成本包含打印物品的价格和所使用的原料。

“If you want to be successful in DTG printing, you need to know how to sell apparel, and how to work with artwork,” Bagley says.“This is about providing value to your customers, but it's also a great way to upsell a current client. You can print out a single shirt based on their design and you've got something that's extra helpful for sales calls.”

巴格利说道:“如果你想要在服饰直接喷墨打印领域取得成功,那么你要了解如何销售服装、如何使用图稿,这是给你的客户提供价值,它也是对当前客户追加销售的有效方式。你可以根据他们的设计喷印出一件衬衣,那么你同样可以获得额外的销售成果。”

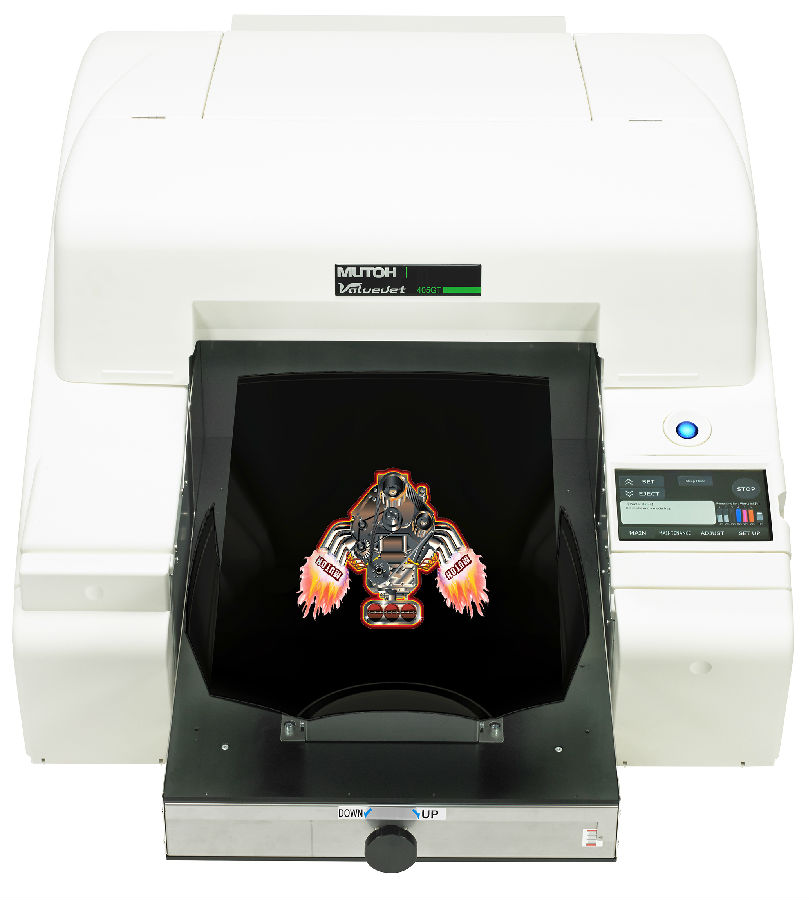

As for future developments, expect to see faster, more compact and more inexpensive DTG technology to emerge, allowing professional-level results on even smaller scale. Randy Anderson, product marketing manager for Mutoh America, Inc., says that integration of pretreatment and drying, available in some high-end DTG equipment, has definitely simplified the process, as has increased integration with current white screen printing technology, to increase throughput. At the same time, Brother has also developed special digital camera add-ons to preview and guide the printing process, providing even more detail.

至于未来期望看到的发展,那就是会出现更简洁便宜的服饰直接喷墨打印技术,甚至更小规模的设备都可以提供专业水平的成果。美国Mutoh公司的产品市场经理,兰迪·安德森说,一些可以实现预处理和风干过程的高端服饰直接喷墨打印设备,已经简化了这些过程,而且通过融合当前白色屏幕打印技术提高了生产量。同时,兄弟公司推出特殊数码摄像头,安装在喷墨打印机上,这样就可以实时预览服装的喷印过程。

“In the middle of the market, platen options allow for a wider range of print platens, not only for a variety of sizes, but a variety of products to include hats, shoes and other specialty market items for personalized or business identity products,” Anderson says. “There is already as split in this industry between high-volume production and the desktop DTG for Mom and Pops. Look to the future to see the desktop DTG become simpler and easier to use while still maintaining quality output, in a more affordable package.”

安德森说道:“在中端市场,喷印压印盘的选择范围很广,不仅包括多种尺寸,也包含个性化的帽子、鞋和其他特色产品或企业特性产品。高产量产品和服饰直接喷墨打印机已经没有关系了。未来可以看到,服饰直接喷墨打印机在保证输出质量的前提下,操作起来会更简单便捷。”