There is just no denying LED is a great "lighting solution" for our industry.

对于我们行业来说,毋庸置疑,LED是出色的“照明解决方案”。

On the other hand, as simple as LEDs appear to be, they are not simple and they are not created equal. There is an LED for almost every lighting need, and in most cases the LED solution offers advantages no other lighting medium in the past can match. That being said, let's get to our two most popular retrofit needs and usage: illuminated letters and sign cabinets.

另一方面,LED虽然表面看似简单,但实际上它们并不简单,以及它们所做的贡献也都不尽相同。几乎每一个照明光源都需要LED,在大多数情况下,LED的优点在于,过去很少有其他的照明介质可以与其媲美。话已至此,让我们来看看两个最受欢迎的改装需求和使用方法:发光字和标识灯箱。

Illuminated Letters

发光字

There is an LED for any sized letter and, to be clear, not all LED modules are created equal nor are all LED offerings UL certified as a "retrofit". For those of you whom might not know, for a CLM (my acronym for Channel Letter Modules) to receive UL acceptance, there are a number of factors that must be met. While this might not be the place to go over these intricacies, rest assured this is a requirement in North America.

LED可以用于任何大小的发光字,但是要弄清楚的是,并不是所有的LED模组都是相同规格的,也不是所有的LED产品都有UL认证的“改装”资格。对于那些可能不知道的人,为了获得UL认可的CLM(“槽型发光字模组”的首字母缩写),必须满足许多要求。但是,你大可以放心,这并不是什么复杂的问题,这仅仅是北美方面的一个要求。

If you are retrofitting illuminated channel letters, they are or were probably illuminated by neon. With this option, the letters most likely have 5" returns, regardless if face or halo lit.This return depth will typically work in your favor and the stroke will also be in your favor to allow you to get your hands in to remove the neon components, stand offs and GTO wiring -- and most importantly to clean the letter interiors.

如果你正在将过去或者现在用于槽型发光字的灯源由霓虹灯光源改装成LED光源,那么你的这一尝试,会使发光字无论是表面还是光晕都更加明亮。这样的亮度不仅对你的工作会有帮助,而且这个尝试对你亲自拆除霓虹灯组件、支架和GTO接线也会有帮助。对于发光字内部的清洁也是十分重要的。

When retrofitting letters, you have two primary options: perform the retrofit as an R&R (removal and reinstall) or perform it on site. If on-site is your choice, things you need to consider:

当你在改装发光字时,你有两个主要选择:拆除和重新安装或直接在现场进行改装。如果直接在现场进行改装是您的选择,那么您需要考虑以下事宜:

On-Site Considerations:

现场改装注意事项:

Access. Overall, letters and site conditions. Remember, site labor is typically the most expensive part of a retrofit and can be compounded by ground-level access--or lack thereof--and power line restrictions, etc.

线路的接入:在现场进行发光字的改造,首先需要考虑到,现场改装劳动力成本较高,你可以通过地面接入(或减少)电源和电线来控制整体成本的开支。

LED low voltage wiring access. This might need consideration if the letters are not raceway mounted. What is the mounting surface? This has a direct effect on your labor if you must drill holes; however, if the original lighting was neon, you might be able to use the neon wire holes.

LED低压线接入:如果发光字不是电缆管道安装,那么就需要考虑哪一面是安装面。如果您需要钻孔,那么这显然会让你的工作变的繁琐。然而,如果已有的原始照明是霓虹灯,那么您可以借用原有的霓虹灯电线孔。

Is there a Raceway? Possibly the easiest retrofit because all of your LED/secondary wiring can be in the raceway without any protective covering.

对于发光字已有现成的管道,这样的改装其实是最为简单,因为所有的LED光源或是二次线路的搭建,都可以直接放置在原有的电缆管道中。

Color saturation. If existing letters had colored faces and colored neon, and you use “white” LEDs, the colored face will not look as saturated. Explain this to your customer-prospect should this be the case.

颜色饱和度:如果现有的发光字有彩色的外壳和彩色的霓虹灯,那么当你使用白色LED光源时,外壳的彩色会看起来不那么饱和。如果是这样,请给你的客户给予合理的建议。

Additional considerations. Older plastic faces and trim cap can be a failure ready to happen under your watch, so you might want to list your potential adders for breakage for your customer in your agreement.

其他注意事项:旧的发光字的亚克力面或者装饰面因为使用寿命的原因,可能随时会发生故障或者破损,因此,你需要在与客户进行此次改造之前,明确地列出这个潜在破损的条款。或者是建议客户对于发光字表面的材料同时进行更换。

Removal & Reinstall Considerations:

拆除和重新安装注意事项:

Same as above, regarding access concerns.

关于线路的接入方面,可参照上面的叙述。

Naturally, you will have labor to remove and reinstall. There might be some liability on your part for older plastics, etc., so do a very good site survey and cover any potential liability in your agreement.

总之,拆除和重新安装对你来说都是没有问题的。一些旧的塑料可能会影响你对发光字安装,对此你需要做一个完善的调查,并将每一个潜在的不利因素在你的协议中注明。

It is possible if there is a raceway, could you leave it on site? Again, a site survey will confirm this.

如果能够顺利地进行电缆管道安装,你会把它妥善放置好吗?进行一个现场调查,你就可以解决这个问题。

Same issues with the face removal, even in your shop.

不管是在什么情况下,外壳的清除都是一个难题,在你的商店里也会是同样的情况。

In your survey, determine if the sign codes changed. This is a very real potential issue regarding major repairs like this. Do not remove anything without checking the applicable code.

你首先需要调查的就是,发光字的相关数据是否改变。这种重大的维修现状是一个非常现实且需要解决的问题。在没有确认完相关数据之前,不要删除任何应用数据。

With the above thoughts, your LED materials will be pretty straight forward with the actual LED, power supply(s) and low-voltage wire. Regardless of either option. Deciding which option is very dependent on any given findings mentioned previously. A set of block letters with 3" strokes and an average number of letters might be easy to do on site. On the other hand, a large quantity of letters or narrower stokes might eat up a lot of on-site labor and the R&R might be a better solution. This option is also somewhat dependent of the weather conditions and available time to work in your shop.

在考虑了上述想法之后,您的LED材料将与实际的LED光源、供电情况和低压电线已经相当匹配。无论做出哪一种选择,都取决于你之前已经了解的信息。当发光字的笔画比较少的时候,现场改装工作是十分简单的,但是,如果需要改装的发光字太多以及铺设LED线路的电缆管道太窄,那么劳动力成本也会随之增加。这时,对旧的发光字进行拆除再进行重新组装就是一个非常好的解决方案了。当然,天气条件和你在商店工作的时间也会影响你做出的决定。

Sign Cabinets

标识灯箱

Our industry is steeped in, "If it ain't broke, don't fix it," and this opens this segment up to the three LED retrofit considerations, once you get past the fluorescent "easy out" mentality. It might very well be your customer demanding the update to LED, for all of the right reasons. So, let's discuss these three LED options and remember as with any retrofit, in any application and market, a site survey and full understanding of the LED system you might be considering is on you:

我们行业有这么一句话,“如果没有损坏,就不要修理它”。一旦你觉得荧光灯需要改装了,并且你的客户也要求更新LED光源,那么你就可以从以下三个方面来考虑LED光源的改装问题。考虑到发光字的广泛应用和市场潜力,你有必要做一个现场调查或是对LED系统有一个全面的了解。现在,让我们来讨论一下LED光源改装的三个要注意的方面。

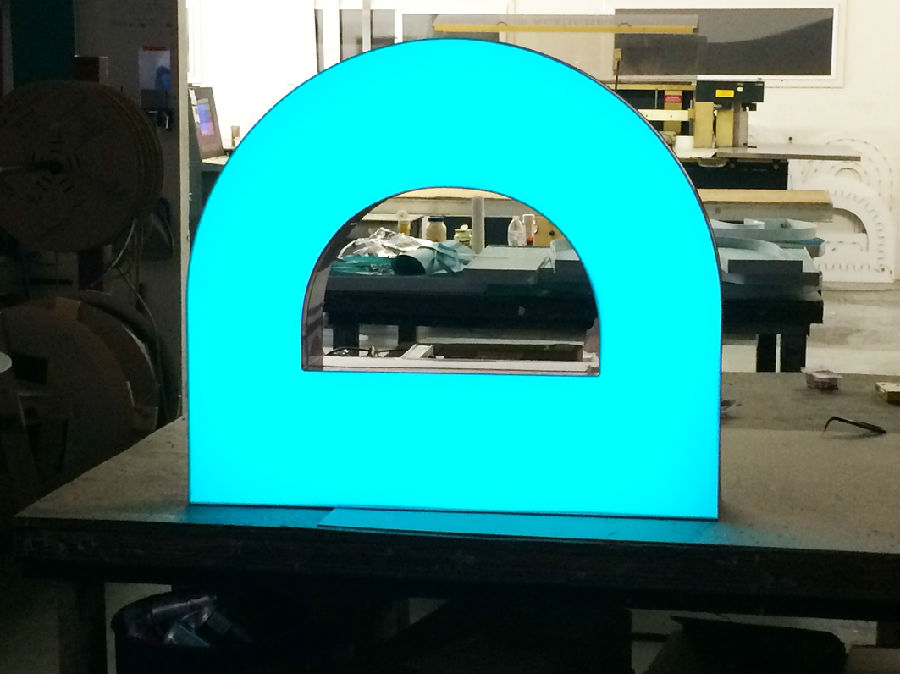

Grid System

网格系统

A grid system is just that, a grid of LEDs, usually featuring vendor/factory preset options. The positive of a grid system is the factory preset options where the performance of even illumination is repeatable every time. These options typically are easy to use by rolling out the LED grid.

顾名思义,网格系统就是一个LED系统的网格,它通常以具有供应商/出厂设置选项为特色。网格系统的优点在于,因为有了工厂预设的选项,所以每次都可以重复使用的发光字的均衡照明功能。这个方法通常很容易通过滚动的LED网格来实现。

With this option, the existing fluorescent parts are no longer needed. The LED grid system can be installed in several customer choice options from an LED vendor track (easy) to your fabrication preferences. If not using the vendor track, it can be as simple as adding a lightweight angle to both top and bottom raceways and securing the grid system. Another is to use the angle on one end of the grid and a spring with an eye hook and J clip ... another very easy and resourceful option.

有了这个选择,现有的荧光照明功能就不再被需要了。从LED供应商的简单建议到你自己的制造偏好,LED网格系统可以按照客户的需要来进行安装。如果不使用供应商渠道追踪,在电缆管道的顶部和底部同时增加一个不那么显眼的角度来确保网格系统的安全也是非常简单的。另一种方法是利用网格的角度,把环眼吊钩和J型弯钩连接弹簧后,将其安装在网格的一端......这是一个非常简单且聪明的办法。

Stick System

条状系统

There are many "stick" options that somewhat simulate the existing fluorescent mindset. However, as with fluorescent, there are considerations to take into consideration:

许多条状系统的安装模式都与现有的荧光系统安装模式有些类似。正因为如此,有些问题也就需要我们纳入考虑的范围之中。

Sign face to lht source if single-faced, and face to face if double-faced. This depth/distance has a direct effect on the final acceptance. Not all fluorescent hot spotting was caused by bad face painting in the days past. It was not common knowledge and not always shared that your lamp to lamp fluorescent spacing was 2x the distance from the face to the lamp. Again, in the old days, most shops put fluorescents on 12" centers as a rule of thumb.

标识表面如果是单面发光的就需要单向光源,如果是双面发光的就需要双向光源。安装的深度和距离都会对最终的成果验收有着直接的影响。不是所有的发光字表面的污点都是由以前的喷涂失误造成的。灯与灯之间的光照距离是人脸到灯光的距离的2倍,这件事情鲜有人知,因此,以前大多数商店在安装荧光灯照明时往往会遵守 12" 中心法则。

My talking point here is you need to take this into consideration if you "think" you can use every fluorescent socket spacing as is. The premise is good, but the site survey will determine the information you should know. And remember, LEDs are directional, thus the same spacing considerations that are prevalent with letters is compounded with cabinets as the light bounce is contained in a larger volume/area.

我说这些是为了告诉你们,如果你想控制好每一个荧光接口的间距,那么你就需要考虑到这一点。有预先准备总是好的,现场调查会帮助你了解你需要知道的信息。并且请记住,LED光源是定向发光的,因此在同一空间中更要注意,当发光字与灯箱共同工作时,考虑到两方产生的光源会产生反射情况,应该将它们安装在更大的空间中进行使用。

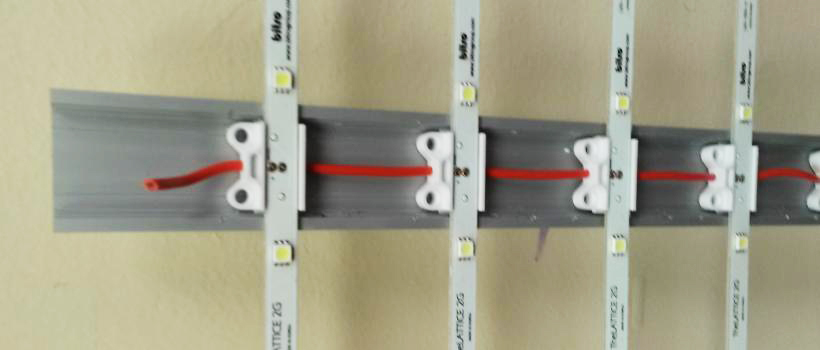

Channel Letter Modules

槽型发光字模组

If your absolute raw material cost is your only consideration, CLM might be your choice. With this option for single face, it can be pretty straight forward by mounting the CLM on the back of the cabinet. Naturally, depending on the cabinet construction, braces, etc., this can range from easy to more involved and needing additional considerations.

如果只有原材料成本是你唯一的考虑因素,那么你也许可以选择槽型发光字模组来进行改装工作。尽管槽型发光字模组仅适用于单面发光,但是将这个槽型发光字模组安装到灯箱后面的程序是非常简单的。当然,安装时也要考虑到灯箱的结构、支架等问题,因为这可以让工作变得更加简单。同时,考虑额外的不确定因素也是必要的。

However, for CLM and double-face applications, it can get tricky. Traditional CLM are modules with light emitting from one side only, thus for double face you need to have a floating center piece to mount the CLM on, typically back to back. I have seen flat bars, clear plastic and even chicken wire grids. Your LED vendor should have a track mounting system for your consideration/use.

然而,如果将槽型发光字模组应用于双面光源的安装,就会使事情变得有些棘手。传统的槽型发光字模组只能进行单面光源的安装,因此如果要进行双面光源发光,您就需要一个可以移动的中心组件来配合槽型发光字模组的安装,通常的安装方法是通过一个“背靠背”的形式来完成的,其材料的选用有扁钢、透明塑料甚至是铁丝网。你的LED供应商应该在售后服务中将相关的事宜和你说清楚并为你提供一些相关的解决方案。

In my humble opinion, there is just too much liability associated with this CLM option; labor can be very high depending on the size, permanent attachment labor can be daunting and there’s a general liability risk of individual CLMs falling off during transit. Both previous options offer better long-term solutions with less liability for you.

我的观点是,选择槽型发光字模组所涉及的相关不利因素太多了。首先它的劳动成本可能会非常的高,永久性的售后服务会令人望而生畏,并且单个的槽型发光字模组在运输过程中还伴随着可能会随时脱落或损坏的风险。之前提到两种方案都能为你提供更好的长期解决办法,并且不利因素也相对较少。

In closing, my approach here is based on general industry experiences over the history of LED in our industry and is not intended to disparage your choice. Additionally, I am defaulting to the simple business understanding of why we are all in business, and that is to make money offering honest products and long-term solutions. I do not believe in lowering my standards and raw costs with the hope of making it up on the service side. I feel my customers are simply too smart, and I want them to see me as a "solution" that benefits them today, tomorrow and in the long term. And if you have read any of my numerous industry articles since the ’90s, I always end with "Buyer Beware," and I do believe that. Do your research because knowledge is everything.

最后,我要申明的是,我在这篇文章中提到的方法是基于我在从事LED行业时所积累的一般行业经验,并没有任何贬低您之前的选择的想法。另外,在做生意的过程中,只要你想赚钱,你就得提供真实可靠的产品和问题出现时的长期解决方案。在不降低我的标准和原始成本的前提下,我可以通过提升服务品质来完善我的产品。我觉得我的客户太聪明了,无论是今天、明天或是长远的未来,我希望他们能把我提供的方法看成是一个对他们有所帮助的“解决方案”。而且如果你自从九十年代以来就读过一些我所写的行业文章,你就会发现我总是以“买家当心”来结束整篇文章。专心于你的研究,因为知识就是一切。