In acquiring that office space they were also awarded signage rights to the top of the building. Allianz decided that they would locate a sign with their name and logo on the top of the building, with an identical sign on each side.

Allianz公司在搬到新高楼之后还拿到了楼顶的标识权,Allianz决定在大楼顶部及两侧安装公司标识。

Spectrum Signs channels Allianz ID

Spectrum标识公司与Allianz标识

Spectrum Signs Inc. (Farmingdale, NY) was commissioned to implement this sign project, and was responsible for fabricating the Allianz signage. The design of the Allianz sign was created by Gensler, (NY, NY), a global architecture firm, who provided concept drawings to Spectrum Signs, upon whom transformed the conceptual design into the final sign structure of a series of closed-face channel letters against an aluminum backplane. Once finished with fabrication, Spectrum teamed up with Empire Erectors and Electrical Co. (Bronx, NY), who were the prime movers in installing the completed signs on the upper reaches of the building top.

Spectrum 标识公司位于纽约法明代尔,他们受委托实施该标识项目,并负责制造Allianz标识。 Allianz的LOGO是由全球建筑公司Gensler(纽约州纽约市)设计的,他们为Spectrum 标识公司提供了概念图,并将概念设计转化为一系列发光字的最终标识结构。 Allianz标识完成制造后,Spectrum标识公司与帝国电力公司(纽约布朗克斯)合作,帝国电力公司成为在建筑顶部上部安装完成标识的主要推动者。

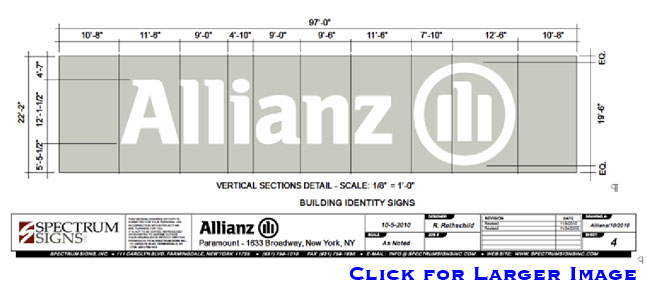

As the Allianz signage was designed, as described by Mike Gyscek, Spectrum Vice President, "the final display was completed as a closed face channel letter sign back lit with Sloan Great White 3Y Series (6500 k) LEDs. There were a total of 12,000 LEDs used to illuminate the four signs. Each 12-foot high channel letter had painted aluminum returns with a ¼" clear Lexan face covering it. Matching each Lexan face was a white 3M diffuser film behind the Lexan. On the Lexan surface was a 3M Dual Color film. During the day the sign face appears blue and at night when illuminated, appears white." Once finished, each channel letter was mounted on its own aluminum background panel (22-feet tall and various widths, depending on letter width it held in place). Altogether each Allianz sign face required ten panels (total sign face was 22-feet x 100-feet) to fully present its corporate name and logo on each side of the building.

正如Spectrum副总裁Mike Gyscek所描述的那样,最终的标识是用Sloan Great White 3Y系列(6500 k)LED组成的发光字。总共有12,000个LED模组组成,用于四个字母标识的光源。每个12英尺高的发光字都涂有铝基反光涂料,其中匹配每个Lexan是一个白色3M保护膜。白天,标识面呈蓝色,夜间照明时呈现白色。标识完成安装之后,每个发光字都安装在相应的铝制背景板上(22英尺高,各种宽度,取决于它固定的字母宽度)Allianz标识面总共需要10块面板(总共22英尺x 100英尺),才能在建筑的每一面完整地展示公司的标识。

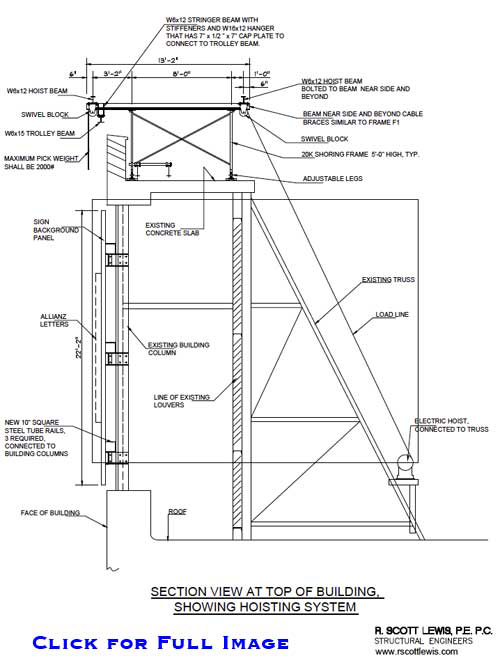

"We, in turn not only fabricated the sign system, but also figured out the engineering to hang the signs from the sides of building," stated Gyscek. "Essentially we came up with the concept of placing a series of steel beams horizontally along the building columns and hanging the sign segments like a giant billboard clamped in place on the side of the building."

Mike Gyscek说:“反过来,我们不仅制作了标识系统,而且还想出了从建筑物两侧悬挂标识的工程计划。我们提出了一个概念,即在建筑物的柱子上水平放置一系列钢梁,将标识部分悬挂起来,就像一个巨大的广告牌夹在建筑一侧。”

Hanging out on Broadway

在百老汇大街悬挂标识

As for attaching the signage to the building, along the rooftop of 1633 Broadway was a series of vertical building columns projecting from the roof to an upper horizontal concrete slab to which each column connected to. The concrete slab in turn held a horizontal platform that encircled the building and had a trolley track from which the building's window washing scaffold traveled around on.

大楼位于百老汇街的1633号,在大楼的天台上有一系列的水泥支柱,每个水泥柱连接屋顶到上面的水平混凝土板上。混凝土板又有一个水平平台,环绕着大楼,一条小车轨道,大楼洗窗户的升降机就是从这条轨道上运行的。

Scott Lewis who engineered the solution for installing the Allianz signs on 1633 Broadway, had suggested using a series of horizontal square steel tubes (ten-inch square) which would span from building column to building column. "Each side of the building had a set of three horizontal steel rails inserted in place for each Allianze sign to hang from the building. Each selected column had its outer sheet metal aluminum enclosure removed at its point of entry so the horizontal steel tubes were able to be permanently attached to the building column. On the steel tubes were welded a series of angel iron plates upon which each sign segment was connected to."

R.Scott Lewis设计了在百老汇1633号安装Allianz标识的解决方案,他建议使用水平方形钢管(10英寸方形),从一根建筑柱跨到另一根建筑柱。他说:“建筑的每一侧都有一组水平钢轨,每个钢轨都是为了悬挂Allianze标识而设计的。每一根选定的柱子在入口处拆除了它外部金属铝板外壳,以便水平钢管能够永久地附着在建筑柱子上。我们还计划在钢管上焊接角铁,方便每个标识都能牢固的连接在这些钢板上。”

Empire Erectors creates sign lift-off Empire Erectors

用导轨式升降机安装标识

Once each sign was completed, at the appropriate moment, each sign segment was trucked to the worksite (1633 Broadway) where its installation was handled by Empire Erectors who were tasked with getting the signs off the street and lifted to the building roof for placement on each side of the building.

标识制作完成后,就会被运送到工地。标识的安装由Empire Erectors全权负责,主要任务就是把标识从街道运送到建筑物屋顶。

To do so involved a series of very clever custom-built hoisting systems incorporating several unique rigging components, including a custom designed winch, a custom-built carrying rig which locked up and lifted each sign panel segment up the side of the building. Finally, on the roof was a custom-built trolley rail system which was set up to move each sign segment to a specific location to be lowered for final placement on the side of building.

为此,我们参与了一系列非常巧妙的定制吊装系统,其中包括多个独特的吊索组件,包括定制设计的升降机,定制的承重设备,将每个标识固定并抬高到建筑物的侧面。最后,在屋顶上有一个导轨式升降机系统,它将每个标识移动到一个特定的位置,然后降低放置在建筑物的侧面。

Rooftop lift without a crane

无需起重机的屋顶升降机

"To begin the lifting process, each building side," James Ramsburgh company Vice President noted, "required a sidewalk bridge installed by York Scaffolding whose surface acted as a base for storing and preparing each sign segment for hoisting to the rooftop. The first procedure was taking delivery of each Spectrum Sign Allianz panel segment and transferring it from the flatbed to the top of the sidewalk bridge. Because all the panels were delivered as extra-wide loads, Empire Erectors could only receive the sign panels at night as extra-wide flatbeds can only travel on city streets from midnight till 6:00 AM.

James Ramsburgh说:“为了吊装标识,每一个建筑侧都需要脚手架,用作储存和准备吊装的工具,方便把标识运送到屋顶。”首先要做接收每个Spectrum标识公司制作的Allianz标识交付。由于所有面板都是以超宽负载的形式交付,帝国大厦的工作人员只能在晚上接收这些面板,因为超宽的面板只能在午夜到早上6点之间在城市街道上搬运。

"Our biggest challenge was getting the signs to the top of the building, as there was no crane available or capable to provide a 750 + foot lift to the building top. And even if there was, once each sign segment was in motion, it would have proven impossible to control the effect of the wind on the panel and its natural swaying tendencies as each sign segment was hoisted towards the roof."

“我们面临的最大挑战是将标识带到建筑物的顶部,因为没有可用的起重机能够为建筑物顶部提供750 多英尺的升力。即使有,也可能因为标识在半空中受风力或触碰到障碍物发生不可预测的危险。“

Inevitably the solution for lifting the signs to the roof was right in front of them. Already in place along the sides of the building was a vertical track system used by the building's window washing scaffold. Empire Erectors took advantage of that vertical track, and built a custom designed winch and rigging system that also worked from the window washing track. They further built a custom designed hoisting rig upon which each Allianz panel sign segment was clipped into and that in turn was connected to the rooftop custom winch. The rig was designed to be locked into the window washing tracks to carry the channel letter panels up the side of the building with no worries about sway or wind to affect the sign panel's passage to the rooftop.

出人意料的是,把这些标识送屋顶的办法就在他们面前。建筑两侧已经安装了导轨式升降机系统,平时它用于建筑物窗户清洗。帝国大厦的工作人员利用了这条垂直轨道,设计定制了一个适用于搬运标识的升降机和绳索工具,该系统也可以从窗户清洗轨道上运行。他们进一步建造了一个新的起重设备,Allianz的每个面板标识都被夹在上面,然后与定制升降机相连。该平台被设计成锁定在窗户清洗轨道上,以便将标识带到建筑一侧,而无需担心风力或其它因素会影响标识的运送。

At the proper moment each sign segment was winched up, and followed by a small Empire crew in Empire's electric scaffold. The scaffold crew then supervised each sign lift session to make sure the sign panel harness rig never snagged on the building and safely reached the top.

于是工作人员就利用该轨道将每一个标识都吊起,然后派人在脚手架上负责跟随标识,监督每一个标识的升降环节,这是为了避免标识卡到建筑物导致物件损坏。

Once on the roof, the sign segment was transferred from the winch to a custom-built rooftop trolley with chain falls, which is a rigging device to help lift and lower the sign segments in place. The trolley was then moved along the rooftop to the sign's proper roof position where the sign panel was lowered in place. Once positioned properly, the sign panel was attached to the steel structure by bolting the panel to the sign structure on side of the building.

一旦上了屋顶,标识就从升降机转移到一个特制的带有链条的屋顶手推车上,用特制的链条帮助固定标识。工作人员用升降机沿着天台移动到标识适当的屋顶位置,找到正确的定位,用螺栓把标识固定在建筑物侧面的钢结构上,然后工作人员再进行进一步操作。

As each part of the Allianz sign project reached completion, sign inspector John Carmona, who reported to R. Scott Lewis reviewed each completed section. Inevitably it took approximately 20 plus inspections to look at each part of the install process, with several different visits to each side of the building. "Altogether there were three types of inspections," stated Cormona,

Allianz标识项目的每一步骤都已落实完成,标识督察John Carmona向R. Scott Lewis汇报,他对每一个完成的部分进行了审核。 Cormona说:“安装过程的每一个部分都要经过20多次检查,对建筑的每一侧都要进行几次不同的检查和询问。总共有三种类型检查。”

1)An inspection of the skybridge for each side of the building.

1)对大楼两侧天桥的检查。

2) Inspections of all the welds and boltings of sign components being attached to structural steel.

2)结构钢上所有标识部件的焊接和螺栓检查。

3) A final inspection of entire sign once it was fully attached to horizontal rails.

3)当标识完全附着在水平轨道上时,对标识进行最终检查。

Once completely installed on all four sides of the building, and illuminated for night viewing, Gyscek noted how amazing it was to see the Allianz sign being visible throughout the entire Manhattan midtown area. "It was even visible across the Hudson River from the New Jersey side and as well, close-up from most of Times Square which was right below it."

Allianz的标识终于完工了,现在它可以在白天夜间正常运作。在夜晚,Allianz标识在大楼顶端发出耀眼的光芒。Gyscek惊喜的说:“它甚至可以从新泽西州一侧的哈德逊河对岸看到,从它下方的时代广场的大部分地方也可以看到。整个曼哈顿市中心区域都能看到Allianz标识是多么令人惊奇!”