Innovative developments in print and cut technologies have given sign shops a number of options they look at when it comes to purchasing new equipment. These options include all-in-one printer/cutter units, roll printer to vinyl cutters as well as flatbed printer to flatbed cutter solutions.

印刷和切割技术近来有了很多创新与突破,比如:一体化印刷切割机,卷筒打印机,乙烯基刀具,平板打印机及其刀具解决方案。这一系列的发展给需要购买新设备的标识制造商提供了许多选择。

Adding the right printer and cutter system to your workflow requires a bit of research plus a thorough analysis of your production processes, from the materials being used to the types of applications you are currently producing as well as other new jobs that you would like to take on in the future.

选择虽多,但要挑选到适合自己的印刷和喷切设备,则仍然需要对生产过程与工作流程作出深入的分析。首先要考虑目前生产的材料类型,其次是印刷及切割使用的应用程序,最后要对未来会去发展的其他工作做好规划。

Advances in Equipment

先进的设备

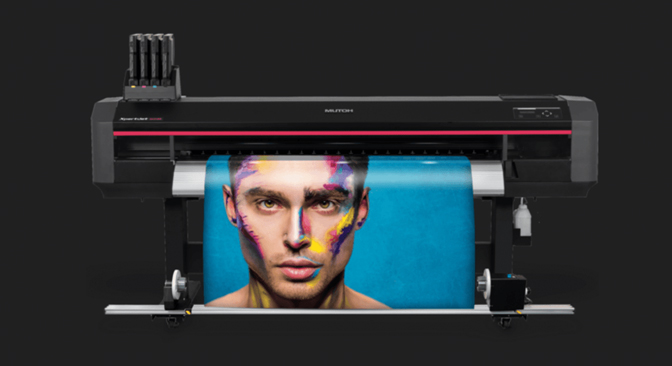

“Print and cut has been a major technique in most sign shops for years. Advances in media and inks has resulted in the horizontal expansion of this method from just traditional vinyl to more unique applications such as packaging and foil decals,” says Mark Rugen, director of product marketing and education at Mutoh America, Phoenix. “As printer technologies advance along with media and inks, no doubt print and cut applications will continue to rise in markets other than signage. In addition, the common trend in customizing and personalizing just about anything will result in further advancements in print and cut far into the future,” he says.

凤凰城Mutoh America公司的销售与培训主管,马克·鲁根介绍说:“多年来,印刷与切割一直是大多数标识制造商的主要技术。而多媒体的发展和油墨的进步,让制造商们的业务横向发展起来,除了传统的乙烯基制造,还多了如包装和箔贴花之类的独特应用。今后在标识制造商们的业务占比中,这类应用还将继续上升。同时也可以看出,一种定制化、个性化的趋势将在标识行业蔓延开来,并会在未来的很长一段时间内引导印刷与切割技术的进一步发展。”

Mutoh公司的一体化印刷与喷切设备

Rugen points out that printers and cutters are changing the digital finishing workflow. “Short-runs are the key phrase or term here. Digital finishing must accommodate the finishing of smaller runs of product. That being said, some printers, such as UV-LED, may actually have finishing inks, varnish that is used to coat the final product or parts of it. On the other hand, more traditional finishing such as laminates may have to be smaller in width since many print and cut applications are smaller in size as well. Finally, the cost of finishing is important and is influencing the development of simpler ways to finish a print and cut product.”

印刷与切割技术的进步正在改变印刷加工的工作流程。“短线”则是这种改变的重要体现,它意味着喷切设备必须适应小批量产品的精加工,而如UV-LED这类的打印机,将作为生产中的一环,被用于在产品上喷涂清漆。另一方面,技术的进步也许将改变传统产品的规格,比如层压板就不得不缩小宽度,以适应尺寸较小的印刷与喷切设备。最后,印刷和切割相结合的产品,可以使用更简单的方法来完成工作,也就意味着成本的降低。

One-Stop Shopping

集成式服务

Daniel Valade, Roland DGA’s product manager of Digital Print, Irvine, California, notes that inkjets with integrated print and cut capabilities are ideal for print service providers (PSPs) looking to grow their businesses, and for those just entering the industry who want to be able to do as many applications as possible with a single device. “While the term ‘one-stop shop’ has been around for a long time, it continues to fuel the demand for wide-format printer/cutters. For applications like Heat Transfer Vinyl (HTV) for apparel, and other types of print jobs that don’t require lamination prior to contour cutting, being able to send a job and walk away from the device while both printing and contour cutting are performed is a big advantage,” he says. “Because there’s no need to remove the media that has been printed on and load it into a separate device, advanced integrated printer/cutters, such as those within Roland’s TrueVIS series, allow for increased productivity and profitability. Because they allow for unattended printing—and are capable of printing and contour cutting even the most complex designs in one seamless workflow—these devices enable smaller PSPs to maximize efficiency and output while keeping labor costs down,” he explains.

位于加利福尼亚州埃尔文市的Roland DGA数码打印公司的产品经理丹尼尔·瓦拉德对此有过专门的说明:集成印刷与切割的喷墨打印机非常适合印刷服务供应商业务增长的需要;对于刚入行的企业来说,则让他们在一台设备上完成尽可能多的任务,以降低成本。尽管“一站式服务”这个词已经出现很长时间,但在今天依然推动着宽幅印刷、喷切设备的进步。最先进的热转印乙烯基技术,在标识以及其他类型的打印工作中,进行轮廓切割前不需要贴膜,且能够发送一个指令使其在完成印刷后自动进入轮廓切割,这样就没有必要在产品完成印刷后将其拿出来,再重新放入另一个单独的设备进行切割,在生产过程中节约了很多时间。

先进的印刷与切割一体化设备,可以极大的提升生产率以及盈利能力。Roland公司出品的TrueVIS系列,即使面对最复杂的设计,也能于无人值守的状态下,自动在一个无缝流程中实现印刷与轮廓切割。这样的设备让小型供应商在使用最少劳动力成本的同时,可以最大化效率和产量。

Roland公司的一体化印刷与喷切设备

Valade adds that the industry is always asking for production level print speeds without sacrificing image quality, as well as the fastest outgassing times possible.

瓦拉德另外补充,印刷行业一直以来的追求都是:在不牺牲图像质量,保证生产水准的前提下,尽可能快的提高生产速度。一体化的设备就是在这个标准下的产物。

Keeping Up With Demand

跟上用户的需求

Michael Maxwell, senior manager at Mimaki USA in Suwanee, Georgia, reports that like many businesses today, print service providers are having some difficulty keeping up with the ever-demanding needs of the consumer. “Delivery times have shrunk significantly, and business owners are forced to multitask and ask their employees to do the same. All-in-one devices offer a functional workflow that reduces the stress of manual interaction and also reduces the stress caused by human error when moving to another device.”

Mimaki美国的高级经理迈克尔·麦克斯韦说:“与当今的其他企业一样,印刷企业也面临着无法满足消费者日益增长需求的困难:交货时间大幅缩短,企业老板被迫同时接手多项业务并要求员工如期完成。这时如果拥有一台一体化设备,就等于拥有了一整套自动、高效的工作流程,可以极大的缓解企业压力。”

Mimaki公司的UCJV一体化印刷与喷切设备

More Customized Products

定制化已成趋势

Gary Buck, vice president, sales and marketing for Summa America, Beverly, Massachusetts, says one of the trends he is seeing is more of a demand for creative and custom designs rather than mass production. “Personalization creates a sense of uniqueness. Although mass production will still exist, we see a clear trend toward creative and custom designs; that will make customers stand out from the crowd and be ahead of competition with solutions tailored to their specific needs. In line with that, we also see a tendency towards personalization and the need to create a sense of uniqueness. More and more people want to identify themselves with the product; they want to feel extraordinary, express their personality, so sign makers need to respond to this trend with more experimental, out-of-the-box, emotional and playful designs.”

马萨诸塞州贝弗利市Summa America公司,分管市场与销售的副总裁加里·巴克表示:“目前,人们对创意和定制化设计的需求越来越大,对于大规模生产的需要则逐渐降低。虽然大规模的生产仍将存在,但对于标识制造商而言,如果遵循创造性与定制化的趋势进行设计,不仅能使他们的客户在市场中脱颖而出,更让企业在特定需求解决方案的竞争中处于领先地位。客户想拥有具有认同感的产品,使想要与众不同的消费者可以表达自己的个性,所以标识制造商需要用更多实验性的、开箱即用的、感性的、好玩的设计来回应这一趋势。”

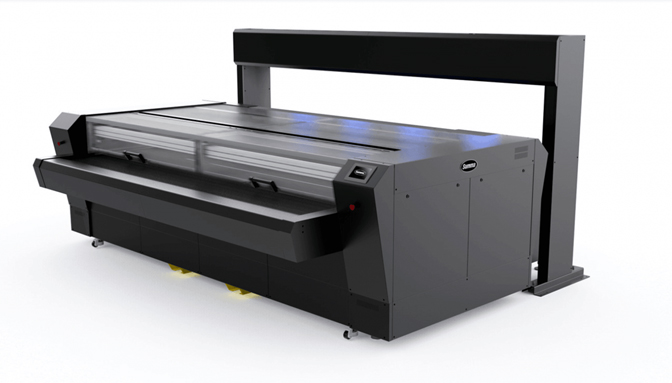

He states that dedicated flatbed cutting systems with integrated print and cut workflow instead of an all-in-one printer/flatbed cutter provide a major advantage of precision and efficiency you get from a dedicated flatbed system. “While the printer is working on a job, the cutter can finish another job, ensuring continuous workflows. Advantages of the flatbed cutters in general are their versatility, enabling users to process a wide range of materials, always with the same high accuracy; modular tooling system and better print and cut workflow integration.”

巴克指出:“一体化的专用平板切割与印刷设备的主要优势在于,比起非一体化的设备,提供了更多的精度和效率,当印刷设备在工作时,切割系统可以完成另一项工作,确保连续的工作流程。而平板切割通用性强,可以加工多种材料,且精度都能保持一致。这种模块化的一体设备可以更好的制造产品并缩减工作流程。”

Buck says that the need for sustainable workflow solutions is another trend in the sign and digital industries. “A company who takes itself seriously can no longer turn a blind eye and has to find ways to utilizing printing and cutting technologies that automate the entire process and find the most efficient method to print, cut and finish with a minimum of waste. So, optimizing entire workflows and process to minimize waste is becoming more and more important.”

He adds that automated systems are key. “Smart functionalities are requested to ensure higher accuracy and boost efficiency. Also, strong software is needed to control the machine and to make optimum use of it.”

可持续工作流程是标识和数码行业的另一个趋势,一个全心投入在这个行业的公司对于工作效率不会再睁一只眼闭一只眼,一定会积极尝试各种最有效的方式来利用或升级自己的印刷和切割技术,使整个过程自动化,以最小的浪费完成运转。因此,优化整个工作流程以减少浪费变得越来越重要。

自动化系统更是重中之重:设备具有智能化的功能,就能确保工作时更高的准确性;而强大的控制软件,可以保证对机器进行最佳利用,提高生产效率。

Sharp Solutions from Summa

Summa公司犀利的解决方案

Buck explains that dedicated flatbed cutters are suited also for mass production for higher precision and higher productivity.

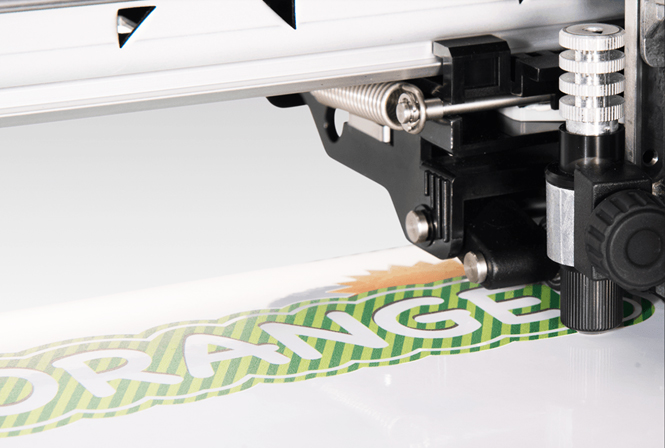

He says that roll cutters are ideal for stickers, paper cutting and patterns for fashion drawings.

平板切割机不仅可以制作精加工的产品,对于需要大批量生产的贴纸、剪纸与时装图纸来说,也是可以提高精度和生产率的工具。

Buck suggests that if a shop is looking for versatility, a flatbed cutter processes almost any material you can think of. “The F1612 is a great entry-level cutter with a small footprint, yet it has the versatility of the larger flatbed cutters in the series. This is a great starting point to expand business to new areas. For roll cutters, the S2 with tangential technology is at the top of the game.”

巴克建议,如果一个标识或印刷公司,正在寻找一款通用性高的喷切设备去加工不同的材料,那么Summa公司出品的F1612就是一个很好的选择。这是一款入门级的喷切设备,却拥有多功能的切割刀具,对于扩展新领域业务是一个很好的起点。而如果需要的是卷切机,采用正向切割技术的S2则会更为先进。

Summa公司的S2卷切设备

Buck adds that the company has also recently introduced their new large-format laser cutter, the L3214.

最近,Summa公司还推出了一款大幅面的激光切割机L3214。

Summa公司的大幅面激光切割机L3214

Integrated Printer/Cutters

强大的功能

Valade points out that integrated printer/cutters have become the standard, and over time, users have figured out ways to shorten their post-production processes with them. “The strongest example of this has been how the perforated cut functionality, in addition to normal contour cut, has made the digital printing process simpler and easier. Instead of users having to rely on ‘tricks of the trade’ to accomplish this type of streamlined workflow, Roland makes it all possible by incorporating a simple one-button addition in its VersaWorks 6 RIP software. This allows users to have both precision contour cutting and a perforated cut in one quick and easy workflow. An example would be a long run of print and cut decals with contour cuts as well as perforated boundaries. With a state-of-the-art printer/cutter like a Roland TrueVIS VG2 or SG2, the decals are all ready to be popped out for individual sale. There’s no need to move the job over to an X/Y trimmer in post-production—the job is already done.”

一体化印刷与喷切设备已经成为新的标准,这是目前用户可以找到缩短后期制作的最好方法。除了普通的轮廓切割外,穿孔切割也是当前用户最需要的一个功能。目前很多用户通过多年的经验与技巧来完成穿孔切割,但如果使用Roland公司制作的VersaWorks6 RIP软件,只需要点击一个按钮,就可以实现这一操作。于是,不论是轮廓切割还是穿孔切割,都变成了一个快速与简单的工作流程。

运用到实践中,一种既需要轮廓切割也需要穿孔切割的贴花纸,如果通过传统工艺制作,就要在印刷后将其移到X/Y修边器上进行后期制作。但放在Roland True VG2或SG2这样一体化的印刷与喷切设备上,这些贴花纸就可以随时生产并出售。

roland-versa-uv-.-printer-cutter Roland公司的VersaUV一体化印刷与喷切设备

decals-roland-printer-cutter Roland公司机器和软件制作出的贴花纸

He says that integrated printer/cutter units offer a number of advantages such as being able to complete jobs that require both printing and cutting—without having to transfer the job from the printer to a separate cutting device—frees up time and helps maximize productivity. “Operators can design, prep and print other jobs while the integrated printer runs unattended. Jobs can be sent at night, when the shop is closed, and when the shop opens in the morning, an entire roll of print and cut decals (or other applications) can be ready to go.”

一体化的印刷与喷切设备有很多优点,比如无需将半成品转移机器;可以在无人值守的情况下进行设计、加载以及自动印刷,这样可以节省时间,最大限度地提高生产率。可以想象,如果使用这样的机器,在晚上公司下班后,无需安排额外的人员加班,工作就可以自动完成,第二天上班时,一卷卷完整的印刷产品就已经放在了眼前。

Potential Growth Areas

潜在的增长领域

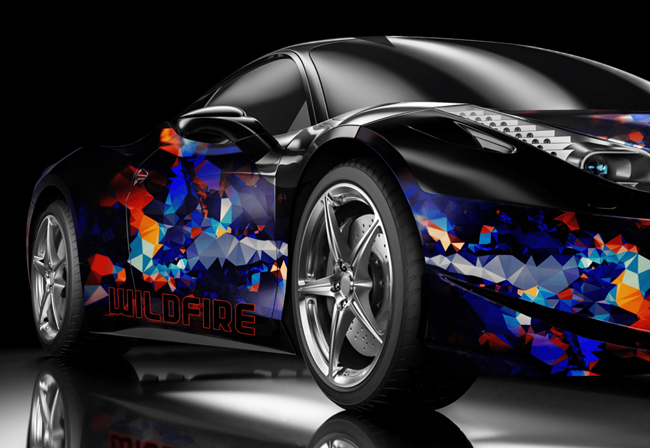

Valade says that with such a wide variety of applications available, and so many media types designed specifically for eco-solvent print-and-cut jobs, the biggest area for growth is to tap into any application the PSP is not currently offering. “Many smaller shops will turn down tougher applications like vehicle wraps due to the complexity of applying the material. The downside to that is the customer will go to a shop that does offer vehicle wraps, and the original PSP ends up losing business to a shop that’s able to accommodate all of the customer-requested applications. Think of a business that has a fleet of vehicles that need branding—the opportunity to produce the decals, posters, and apparel that can all go along with that same request can be lost. To help businesses add vehicle wraps to their product offerings, Roland offers Born-to-Wrap workshops throughout the year in many locations across the country. These workshops take the mystery out of design, printing, application, and even job costing, to give attendees the confidence to bring this application in house.”

随着各种应用程序的广泛使用,出现了许多专为环保打印和切割工作而设计的多媒体设备,可以想见,当今印刷与标识公司最大的发展取决于其所能做出的差异化。许多小门店会因为应用材料的复杂性,会拒绝像汽车包装这样专业且严格的工作,这样做的缺点是,客户会不断流失,去寻找另一家提供汽车贴纸、包装服务,或是能够满足更多客户要求的商家。试想一下,这会丢失多少生产贴花、海报或是贴膜的机会,而这些都是一家印刷公司应该拥有的服务。

为了帮助印刷公司在其产品中添加汽车包装服务,Roland公司在全国各地全年提供汽车包装车间,并且开办相关的研讨会,将汽车包装的设计、印刷、安装甚至整个工作成本的计算都公之于众,让与会者有信心进入这个新领域。

Vehicle wrap produced on the Roland TrueVIS VG2-640 printer-cutter. Image courtesy of Roland DGA.Roland True VIS VG2设备制作出的汽车包装。

Software is Key

关键:软件

Maxwell points out that each print-and-cut workflow essentially offers the same result. “Where the benefits lie is the interoperability of these units through software of partnerships. Enhanced workflow features such as Mimaki ID Cut reduce potential alignment or loading errors when moving from a print-only device to a cut-only device.”

从本质上来说,印刷与切割的工作,不论用什么机器做,都会产出相同的结果。但是对于一体化设备来说,每个单元都可以通过软件增强协调能力,比如Mimaki ID Cut,就减少了从印刷设备转移至喷切设备时出现的对齐或加载错误。

Maxwell says that print-and-cut functionality is almost a necessity in any print facility due to increased customization demands from consumers. Items including decals, labels, POP, POS, and custom signage are common and each one is unique, which creates a challenge for PSPs.

印刷与标识公司现在面临的挑战是:由于消费者定制化需求的增加,增加贴花、标签、流行、销售等元素甚至自定义标识的要求都很常见,且每个设计都是不一样的,但打印机和切割机却只有固定的那些功能。

Maxwell adds that Mimaki offers a highly integrated and seamless print-and-cut workflow solution. “The company’s popular CJV and UCJV Series offer advanced unattended operation for roll-to- roll goods and are a great addition to any traditional print shop.

Mimaki公司的UCJV一体化印刷与喷切设备

Mimaki提供了一个高度集成和无缝的印刷与切割工作流程,让公司最受欢迎的CJV与UCJV系列产品也加入了先进的无人值守与卷切功能,这对于任何一家传统的印刷公司都是一个强大的助力。

Recently, the company has added laser and rotary engraving/cutting functionality to suit certain application needs. This opens up a print-then-cut workflow to customers using Mimaki JFX and UJF Series products, giving them the ability to easily expand their offerings.”

针对定制化的潮流,最近Mimaki增加了激光旋转雕刻与切割功能,以满足用户的特定需求,这为使用Mimaki JFX和UJF系列产品的用户打开一扇全新工作流程的大门:“先打印,后切割”。让扩展产品、满足消费者需求等任务可以被轻松完成。

Plenty of Options Available

选择虽多,考虑更多

Rugen says that due to the rising and continuous popularity of print and cut applications, there is no “right” combination of printer and cutter equipment. “Some choose to combine both printer and cutter into one device, some separate them. Some devices are roll-to-roll, others flatbed. The choice of equipment and methods depends much on the applications anticipated and maybe even the experience of the operators. As an example, if print and cut is to be used for the packaging market, a flatbed cutter may be needed. In addition, combination printer/cutter equipment is by far easier for the newer user but has two possible drawbacks. One, if the media must be finished with a laminate it will have to be removed from the printer/cutter anyway and reinserted for cutting, and two, if there is a maintenance issue with either printer or cutter, the entire device may be inoperable. A separate printer and cutter combination is more versatile in most cases,” he says.

由于印刷和切割应用的不断增长和普及,已经没有所谓印刷机与切割机的“正确”组合这一说法。有些企业会使用一体化设备,有些则会用多台设备,有些使用卷切机,有些则选用平板切割。要知道,选择生产设备和方法很大程度上取决于具体的应用,甚至取决于操作者的经验。面向包装市场的印刷与切割,可能需要平板设备;对于新用户来说,一体化设备会更容易操作。

一体化设备同样有缺点:第一是产品如果必须使用层压板,也会出现转移机器进项再加工的情况;第二是在一体化设备里,不论是印刷装置还是切割装置需要进行维护,都会导致整个设备无法运转,独立的印刷机和切割机在这方面也许会更加的灵活。