One thing that I learned from the electronics industry is that if you make something smaller or

less expensive, there is usually a demand for it. This also holds true in the sign industry where people are looking for ways to save money with a trend toward customers wanting lower-profile backlit signage.

我从电子行业中学到的一点就是,如果你要制作某些更小更便宜的产品,那一定是因为它有强烈的市场需求。在标识行业中,这一点同样适用。标识行业中,有一部分客户为了省钱倾向于低调的背光标识。

But customers often get sticker shock when they find out that their elegant, thinner sign actually costs much more than a deeper one, as many sign makers just add more LEDs to try and make the sign look evenly lit. In this article we will take a look at diffuser films and their applicability with some newer LED light sources designed to reduce cost and optimize performance in backlit sign applications.

当客户在发现他们的高雅纤细的标识实际上比那些更厚的标识成本高很多时,他们就会被产品的价格影响。例如,很多标识制作者为了让标识发光均匀,就在标识外壳里面简单地增加LED灯的数量。这篇文章将要向大家介绍LED扩散膜以及它在一些新型LED光源中的应用,这种新型的LED光源具备节能、亮化效果明显的特点。

Illumination Factors

照明因素

Figure 1: The relationship between light on the face of a sign and distance from the LED.

图1:标识表面的亮度与点光源到标识表面的距离之间的关系。

No one wants an illuminated sign that has hot spots or stripes. So recently, a lot of effort has gone into developing various products (from the light source, to diffuser materials and even paints) that are designed to improve evenness of illumination. In backlit signs, the evenness of illumination on the sign face depends on a number of factors, including:

·The spacing of the lighting

·The optical distribution pattern of the light leaving the source

·The distance of the lighting from the face

·The optical characteristics of the substrate and films

·The reflectivity of the interior of the sign

没有人会接受由于发光不均匀产生的光点和带条纹的发光标识。所以,近期很多企业开始在光源、散光材料甚至图形上下功夫以改善标识发光不均匀的问题。在背光标识中,标识表面的发光的均匀性取决于以下因素:

·照明的间距

·点光源发光的分布格局

·电光源距离标识表面的距离

·基片和扩散膜的光学特征

·标识内部的反光率

It turns out that light as a function of distance follows what is called an inverse square relationship (1/R2). Therefore, if you have a single LED module that is evenly lighting the face of

a sign at 1,000 LUX or lumens/m2, and you begin increasing the depth of the sign, the light will drop according to the following relationship or pattern:

1” from the sign face = 1,000 LUX

2” =250 LUX

3” = 111 Lux

4” = 62.5 LUX

实验发现,光的亮度与距离之间成平方反比的关系,即1/R2。因此,如果你用一个1,000 LUX的发光均匀的LED模组来照亮你的标识的话,你就需要增加标识的厚度。因为标识的亮度将会遵循以下规律:(”代表英寸,LUX是亮度单位“勒克斯”,左侧代表LED光源距离标识表面的距离。右侧代表需要的光强度。)

1” from the sign face = 1,000 LUX

2” =250 LUX

3” = 111 Lux

4” = 62.5 LUX

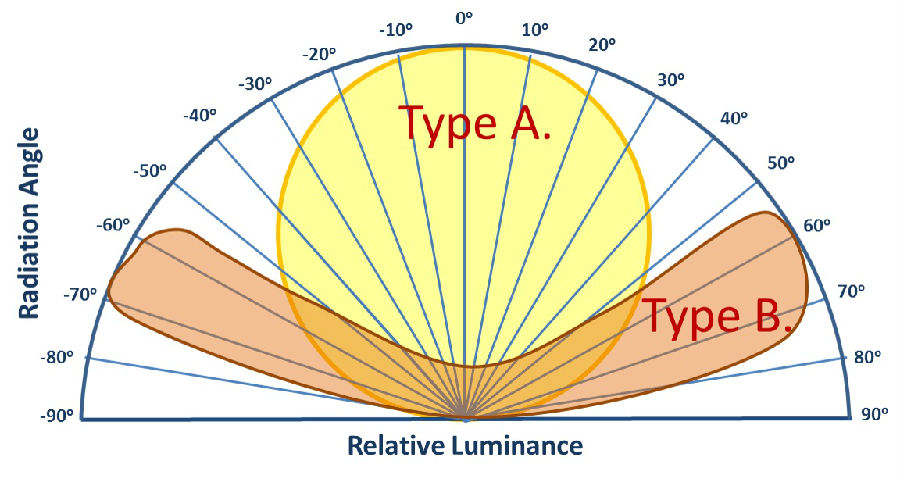

Figure 2: Lambertian LED (A) compared to Batwing optics (B) profile.

图2:LED传感器模式(A)与羽翼状光学模式(B)对比图。

Simultaneously, you can cover exponentially more surface area by increasing the distance between the light source and the sign face (see Figure 1). Historically, most LEDs (and many other light sources) all had a Lambertian optical profile with typically a 120 degree beam angle and a largepercentage of the light directed at the face of the sign (see Figure 2). Using these LEDs, theonly option was to vary the spacing between each light source or increase the depth from the face of the sign.

同样地,你也可以通过增加标识的厚度来扩大点光源到标识表面的距离(如图一所示)。一般情况下,大多数LED和很多其他的点光源都有一个光传感器,它有一个120度的发光幅度,这部分光线直接照到标识的表面(如图二所示)。使用这些LED或者点光源时,唯一的操作就是调整每个点光源之间的距离或者调整标识的厚度以改变光源与标识表面之间的距离。

Even today I bristle when I go into sign shop and see guys literally sticking LEDs one right next to another to “make the sign even.” Often I have this recommendation: "You need to quit thinking about cost per foot and start thinking about cost per use." There is definitely a better, more economical, and more energy efficient way to evenly light low-profile signs.

当我在标识加工的店面里看到有人为了制作一个发光均匀的标识,在一个接着一个安装LED光源时,我就生气。通常我会建议他们:“你不要想着节省每英寸标识的成本,你应该思考如何提高每个LED的使用率。”这才是一个制作发光均匀的低调的标识的最好、最节能、最经济的方式。

Batwing LED Optics

遵循LED光学原理

Today many LEDs are available with batwing optics profiles from a number of manufacturers, which serve to redirect the light laterally at a relatively high efficiency. This virtually increases the “depth” of the sign by forcing the light to travel a longer distance and resulting in mixing of the light between modules. This can serve to reduce installation time and overall costs. Itcan also allow for illumination of backlit signs as low as 1.5”. There are a number of types of batwing optics available.

现在,很多制造商都有生产带有翼状光学器件的LED,它们的主要特征是有极高的反射率。事实上,他们强行改变光的路线,增加光的射程,间接增加了标识的厚度,导致不同模组发出的光混合在一起。这不仅会减少安装的时间和成本,还可以让背光标识的厚度低至1.5英寸,而且还会有很多背光标识可供选择。

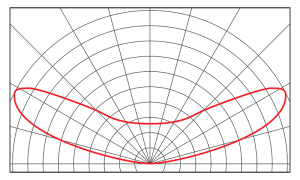

Figure 3: Specialized batwing optic for very low profile signs.(Image courtesy Principal LED, San Angelo, Texas.)

图3:专为低调的背光标识使用的翼状光学配件。

Standard batwing optics will create a more flat optical pattern. One of the more specialized optics is employed on our new Street Fighter Slim Mod. Its donut lens construction really pushes light laterally, making it the first module of its type that can evenly light signs as low as 1.5” in total depth on reasonable spacing,” says Nick Kadlacek, Engineering Tech. with Principal LED (see Figure 3).

标准的翼状光学配件会创造一个柔和的光学模式。有一个更专业的光学配件在我们的新的Street Fighter模组中,环状透镜结构有很好的散光功能,让它成为适当空间范围内第一个真正低至1.5英寸的均匀地点亮标识。

The point is that a number of LED manufacturers' specialized modules can evenly light many surfaces at relatively shallow depths. By purchasing the right LED for the right job and optimizing the depth and spacing, you can avoid the need for diffuser vinyl in many cases.

问题是,很多LED模组的生产商专注于那些在相当浅的层次上均匀照亮标识的LED模组。购买正确的LED,设置最佳的标识厚度和空间,或许可以避免使用扩散膜。

However, all practicing sign makers know that there are ALWAYS exceptions. Many highly translucentacrylics and certain other substrates may be specified for a specific color (or other reasons), resulting in a sign that has hot spots even with batwing type optics. In addition, polycarbonate faces and some flexible face material do a poorer job diffusing light. In these cases, a diffuservinyl is definitely necessary.

然而,所有的标识制作者都知道任何时候总会有一个例外。很多高透明的亚克力板和其他的基板可能会被指定一个特定的颜色,这会造成标识会产生热点,即使它有翼状光学配件。另外,PC板的表面以及一些柔性材料表面的散光效果不是太好,这种情况下,一块散光板就很有必要了。

First and Second Surface

背光标识的结构

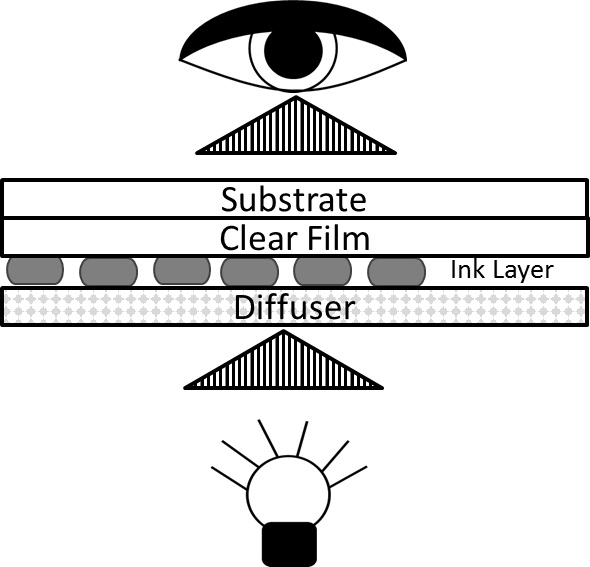

Figure 4: Structure of typical first surface graphics.

图4:标识正面的典型结构。

If you are using a diffuser film and a rigid substrate, the diffuser film can be applied directly to the opposite side of the substrate as the film is applied. For many constructions, this is an excellent way to avoid three consecutive film layers. For backlit signs with graphics, there are two general constructions:

如果你使用的是扩散膜和刚性基板,扩散膜可以直接用在刚性基板的对面,对于很多结构来说,这是一个极好的方法来避免三层连续的薄膜。对于背光标识来说,一般有两种结构:

First Surface OptionFirst surface graphics are those in which the graphic is printed right facing,where the ink ison the visual side of a translucent film (or substrate if printed directly). Often an over-laminate is applied to protect the ink (see Figure 4). Second Surface Option—Second

surface backlit graphics are printed as a mirror image, and in this case the clear film or substrate also serves to protect the image (see Figure 5).

第一种选项——正确打印的正面,墨水印在可见的半透明薄膜上(或者直接打印在基板上)。通常会有一层压层薄膜附在墨水上(如图4所示)。第二个选项——背光图样应该打印成镜像的样式,这种情形下,依然有透明薄膜或者基板附在表面以保护图像(如图5所示)。

Figure 5: Structure of typical second surface graphics.

图5:标识背面的典型结构。

It is important to check with the manufacturer for the correct diffuser film type, as certain films are suitable for second surface application only. In addition to creating a more even overallillumination, diffuser films are also useful when you need to create varying degrees of illumination on the face of the sign. For example, diffuser films can be applied as a second surface application behind a background color or secondary line of text to reduce its brightness, while a logo, for example, can be fully illuminated for maximum emphasis.

与制造商检查确认扩散膜的类型是否正确是非常重要的环节。因为,有些扩散膜只适用于标识背面。除了创建一个整体发光均匀的效果外,在你创造不同亮度的标识时,扩散膜会发挥很大的功能。例如,扩散膜可以作为背面的背景颜色或者用来减少亮度。有时,一个LOGO恰当的亮点或者亮度都可能成为它的亮点。

Light Control Films

光控薄膜

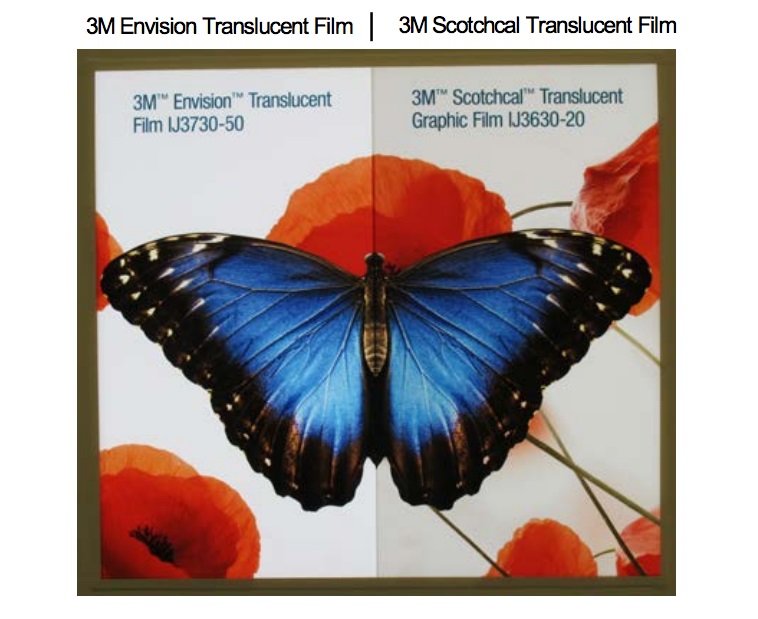

3M carries a wide range of lightcontrol films and substrates. The Envision family of both diffuser and translucent films are specially formulated to work with LED light sources and retain up to60 percent light transmission. According to 3M, they offer this improved light transmission while still diffusing the LED light.

3M公司推出一系列的光控薄膜和基板。他们的扩散膜和半透明薄膜都是为LED光源特制的,这些薄膜和基板的透光率都在60%以上。据3M公司所说,这些产品在扩散LED光的同时还能改善其穿透率。

Recent advancements in both diffuser films and LED technology have led to brighter, even illumination with fewer LED modules required. (Image courtesy of 3M)

最近,扩散膜和LED技术的发展使LED越来越亮,亮化中需要的LED模数量也减少了。

I was able to see a demonstration in which application of this film to the sign face required 40 percent fewer LEDs, while providing the same surface LUX and even illumination. I was also impressed with the coloration of the 3M material, which not only increased the light, but visuallyseemed to keep a “purer” color that was not a dull greyish blue as with the standard diffuserfilm. This may have been more of a brightness effect more than a true color shift, but regardless the visual benefits were clearly apparent.

我有幸看到一份文件,上面说这种类型的薄膜在减少40%的LED灯的基础上能到达相同的LUX甚至更亮。我对3M公司的材料颜色印象深刻,它不仅提高了亮度,而且视觉上颜色更纯,不是那种带有标准扩散膜的沉闷的灰蓝色。这可能是亮度提高带来的效果而不是颜色的变化,但视觉效果确实提高了不少。

“We utilize Envision diffuser film any time we are using a colored vinyl face with a clear polycarbonate substrate for channel letters,” according to Michelle Geyer, a design engineer at Kieffer & Co. “We have also been matching the 3M Envision film on shallow letters with some newer opticsbased LED technology. This allows us to create new designs and reduce overall energy costs,” adds Geyer. Envision films are also come with a nineyear nonprorated 3M MCS warranty. Application notes and technical bulletins are also available on the 3M website.

Kieffer & Co.公司的设计工程师Michelle Geyer说:“只要我们在发光字里用PC板和上色的亚克力板,我们就用Envision的扩散膜。我们已经利用先进的光学LED技术将3M公司的Envision薄膜和薄的发光字联系在一起了。”Geyer 补充道:“它们不仅使用灵活而且耗能少。”Envision薄膜还有一个9年的3M MCS担保,操作说明书和技术说明在3M的官方网站上都能找到。

An Important Tool

必备工具

Diffuser graphics are an important tool for not only creating more even illumination or reduced light intensity, but can be used effectively to vary the light, highlighting certain text, images,or logos. Diffuser films can be also used effectively with the latest LED technology that utilizespecialized optics to create new form factors and lower profiles in backlit signs.

散光器是一个非常重要的工具,它不仅有助于光的均匀分布、降低亮度,还可以区分不同的光、突出特定的文本、图画和LOGO等内容。在新技术的帮助下,扩散膜还可以根据特定的光学原理用开发新的照明材料。