Advances in printing, ink and fabric technology have made grand-format textile printing a strong growth area, particularly in the retail, home goods and trade show industries. This growth is attracting both sign and graphic shops as well as manufacturing companies to the textile industry.

打印技术、供墨系统和纺织技术的发展已经促使宽幅织物喷绘行业发生了巨大的变化,尤其是在零售商店、居家装饰和商业展览等行业。这一增长也吸引着标识和喷绘公司和一些制造公司进军织物喷绘领域。

Mike Wozny, senior product manager for EFI, says that his company recently entered the digital textile printing market with its July acquisition of Reggiani Macchine, which is based in Bergamo, Italy.

EFI 公司的高级产品经理Mike Wozny说,最近他们公司在七月份收购了Reggiani Macchine(位于意大利贝加莫,是一家以技术领先的供应商,在以水性墨水为基础的纺织品印刷中,拥有广泛的工业喷墨打印产品线)并顺利进入高速发展的纺织数码喷绘领域。

Reggiani’s inkjet technologies have been rebranded as EFI Reggiani and provide an extensive lineup of industrial inkjet printers that use water-based inks to print on fabric for the fashion and home furnishing textiles markets.

Reggiani的喷墨打印技术将以全新的品牌EFI Reggiani面向市场,拥有全系列高级纺织打印技术的多款打印机,包括水性墨水、酸性墨水、颜料性墨水和活性颜料墨水。以水性油墨为基础打印的织物产品主要用于服装与家具装饰领域。

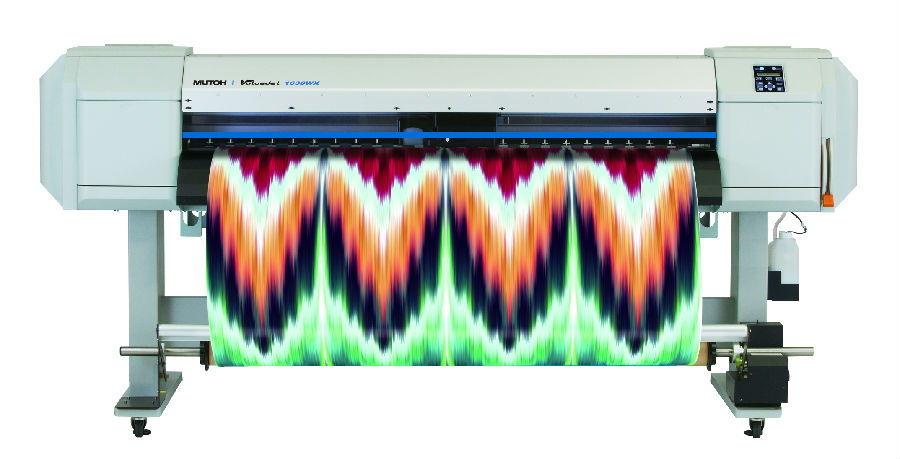

The Mutoh 1638WX can print dye-sublimated fabric at speeds up to 1,012 square feet an hour. Photo courtesy of Mutoh.

Mutoh 1638WX设备可以每小时1012平方英尺的速度热升华打印纺织品。

BIGGER, STRONGER, FASTER

更大、更强、更快

Every year, the industry requests direct to fabric printers that can do the job faster and with a higher quality but at a lower price. And every year, the industry delivers, Wozny says.

每一年,市场的快速发展对织物打印设备的速度、打印质量和价格的要求不断提高。并且,织物打印的发展每年也在快速发展着。

HP collaborated with CR&A Custom, Inc. (CR&A), a grand-format digital printing company, to transform a pediatric treatment room at California-based White Memorial Medical Center (WMMC) into an ocean adventure using HP Latex printing technology. The underwater-themed interior design project aims to inspire feelings of peace and tranquility.

HP collaborated with CR&A Custom, Inc. (CR&A), a grand-format digital printing company, to transform a pediatric treatment room at California-based White Memorial Medical Center (WMMC) into an ocean adventure using HP Latex printing technology. The underwater-themed interior design project aims to inspire feelings of peace and tranquility.

为了改变加利福尼亚纪念医疗中心的一个儿科治疗室的房间,惠普与另一个宽幅数码喷绘公司CR&A Custom合作,利用惠普的乳胶印刷技术,将其改造成一个海洋生物的世界,这个以水下世界为主题的设计旨在激发儿童宁静和平的心境.

“We have made significant inroads in the garment and home décor markets. When you hit the speeds we are hitting at the acquisition prices we are offering, the total cost of ownership is one-fifth of what it was five years ago,” he says. “Digital is more stable but much more mainstream in that textile garment industry as a result. They are making inroads into what was traditionally an analog business. It is much more digital today. As a result of that, a lot more industrial applications are coming online. Instead of painting a wall, you can use fabric today to change the look and feel of a room or hotel or overall space.”

Wozny说:“我们在服装和家居装饰方面已经做了巨大调整,当别人在调整速度时,我们在调整价格,我们现在的成本只是五年前的五分之一。但数码打印已经成为行业的主流了,并且发展迅速,现在都已经出现在线打印服务了。而不是直接粉刷墙壁,你可以通过织物喷绘来改变卧室或者宾馆的墙壁或着整个空间。”

The EFI Reggiani line of printers can print with 4 picoliter ink drop sizes at 8,000 square feet an hour. Three years ago, those speeds were unheard of. That has a lot to do with advances in printhead technology. “They are more reliable, more repeatable, more accurate printheads,” he says. “The data paths to drive those printheads; the amount of data required to drive that is significant. And then the ink technology, along with the architecture to support it, has come a long way as well. If you look at the ease of use on inks, the consistency, it is a much better situation today than five to 10 years ago.”

EFI Reggiani工业喷墨打印产品线可以一个小时打印4升的墨水,像素达到8000。三年前,这个打印速度是前所未闻的,这对喷头技术的要求很高。他说:“这些喷头更可靠、可重复使用、更精准。其中,驱动喷头的数据路径以及数据量都很重要。其次是油墨技术也获得很大的进展。如果你看到油墨使用的便捷性和相容性,你也会觉得今天的织物喷绘条件比十年前优越很多。”

The fabrics that are available for soft signage are also more advanced. They are softer, brighter and are more likely to be used in a direct printing application, he adds. “Now there’s a good line of direct fabrics that come online that still have a very soft hand or feel to them that receive the ink well and provide an excellent image quality,” Wozny says.

他补充道,用于软标识的织物更是进步了很多。它们更软、更亮,且在喷绘设备上更容易直接喷绘。Wozny说:“现在可以线上直接进行织物打印,而且织物的手感很柔软,墨水容易吸附,不易掉色,图像质量也非常高。”

Terry Amerine, director of product marketing at Durst Image Technology US LLC, says that direct printing to fabric profit margin opportunities are increasing. Fabric is more appealing because the creases and crinkles disappear when fabric is stretched, so “it is much cleaner, sharper and more aesthetically pleasing.”

Durst Image Technology US LLC 公司的营销经理Terry Amerine说,织物直喷的利润率也在不断上升。在服装领域,人们更喜欢织物,因为它不易褶皱,很容易舒展。因此,它看起来“更干净、更易塑形、审美上更吸引人。”

Amerine adds that while the visual appeal is a huge part of what drives the demand for printed textiles, fabric is also lighter than vinyl and easier and cheaper to ship cross country. “If you look at the major retailers and the number of locations they are shipping to, it is a cost savings. They are focusing on their carbon footprint, their sustainability strategy and this plays into that,” he says.

Amerine补充道,尽管视觉上喷绘织物可能更有吸引力,但是织物比亚克力更轻、更便宜,储存和运送也更方便。他说:“如果你去了解一下当地的标识店铺以及他们主要的发货地点,你会发现织物标识会节省出一大笔的运输费用。”

SUSTAINABILITY

稳定性

Fabric is more sustainable than PVC. In the trade show industry, fabric banners can be folded up and reused, and they also can easily be cleaned. “When you look at the aesthetics, freight savings and the durability … it is a better choice. It has a lot of advantages to it over a PVC banner,” Amerine says. The home goods market has become a big buyer of printed textiles. Many companies are purchasing printed textile wall coverings and draperies. Backlit signs are also in huge demand.

织物比亚克力的稳定性更好,在商业展览会行业中,广告旗帜和横幅可以折叠并重复利用,而且清洗也很方便。Amerine说:“考虑到美观、节省运费和稳定性方面时,织物是最理想的选择。和亚克力标牌相比它有众多优点。”家具用品市场已经成为织物喷绘领域发展的巨大推动力,很多公司都在用喷绘织物装饰办公环境,背光标识的市场需求依然很大。

In the past, most fabrics used a dye sublimation process, which is a little more complicated than printing directly onto fabric. With direct to fabric printing, the fabric is pretreated so that it will accept the dyes. In dye sublimation, there is an additional step that involves transfer paper. Direct to fabric printing is cheaper because it eliminates the need for transfer paper, which speeds up the entire printing process. Printers also use water-based inks, which are more environmentally friendly.

以前,绝大多数的纤维织物应用的是热升华打印技术,这比直接打印要复杂的多。进行热升华打印之前要将承印物提前预热,染料才能附着在承印物上。而且热升华打印需要复写纸。直接织物打印更便宜因为它不需要复写纸,打印过程简单方便,用时短。而且还可以使用水性油墨,更环保。

EXPANDING APPLICATIONS

拓展应用程序

A large growth area for printed textiles is the home goods industry. These images feature HP’s Photo Canvas substrate.

织物喷绘领域增长最快的就是家居装饰领域。

Durst produces all kinds of wide-format fabric printers. Its Rhotek series 322 are inkjet printers that are great for industrial soft signage applications. Durst’s Alpha series printers are multi-pass inkjet printers designed for the home textiles and fashion industries. The Alpha 330 is a massive unit that can print 11,000 square feet of fabric an hour and is in high demand in the home goods market. The Alpha 180 TR is a dye-sublimation printer for polyester and polyester blends that can also print direct with the addition of a direct-print kit.

Durst公司提供各种类型的宽幅织物喷绘设备,他们的Rhotek series 322设备是喷墨式打印机,主要用于工业软标识的生产。Durst公司的Alpha系列设备多通道喷墨式打印机,主要服务于家纺和服装生产行业。Alpha 330是一个功能强大的设备,每小时可打印11000平方英尺的织物和家居用品市场的高需求产品。

The trade show industry is in love with fabric. If a company needs to purchase 100 PVC banners, one for each exhibition, it costs a lot of money. With soft signage, a company can buy 10 banners and ship them from exhibition to exhibition. “You pay a little more for that banner than traditional vinyl, but you can pack it up, put it in a small package and ship it to the next exhibition. Roll it out, smooth out the creases and use it again,” Wozny says. The person hanging up the banner has an easier time of it as well because fabric is easier to install. Fabric has a higher value look and feel to it, which makes customers feel that their marketing dollars are providing them a better return on their investment, he says.

商业展览会行业始终钟情于织物软标识。如果一个公司在一个展会上需要100PVC横幅,这会花费很多。如果购买了10个织物软标识的话,可以从一个展会带到另一个展会,重复使用。Wozny说;“织物可能会比传统的亚克力成本稍微高一点,但是织物标识可以重复利用,打包收起来带到另一个展会重复使用。”拆卸横幅标识方便省时。织物的视觉体验价值更高,让客户有一个更高的投资回报体验。

“When I go to a lot of events and do internal training with customers, one thing I hear is how can I continue to expand my product offerings and increase my bottom line,” says Candyce Holcomb, the Americas large-format category manager for Hewlett-Packard. “The printing market is becoming more competitive. Printers are more efficient, easy to use and people are printing signs every day.”

美国惠普公司宽幅产品经理Candyce Holcomb说:“每当我在给客户做内部培训时,我经常听到的一个提问是我如何扩大我的产品提高价格。打印市场的竞争越来越激烈,打印设备的效率也越来越高,越来越方便,供应商们每天都在给客户提供打印解决方案。”

There are new opportunities to go into décor, wall coverings and things of that nature. Most print service providers are already making signs. They are already well-versed in sign display so it is natural and organic to move into textiles and fabrics,” she says.

织物喷绘在家居装饰和墙纸等方面应用的很多,很大一部分的供应商已经开始将织物喷绘运用到标识领域了。他们精通标识展示,顺其自然就把织物引入了标识制作中。

CUSTOMERS DEMAND MORE FABRIC

市场需求不断扩大

“We live in a one-stop shop kind of world. We want to go to one place to buy everything we need,” Holcomb says. The same holds true in the sign market. If customers can purchase vinyl signs and fabric wall coverings all in one place, they are more likely to give that shop repeat business.

Holcomb说:“我们渴望生活在一个一站式服务商店的世界里,希望有一个商店可以满足我们所有的需求。”在标识世界里也是如此。如果一个客户在一个标识店铺里即能买到亚克力标识也能买到壁纸的话,他一定会与这家公司建立长期的合作伙伴的。

Randy Anderson, product manager for textile at Mutoh America in Phoenix, agrees, saying he expects that in the not too distant future, customers will be able to walk into the local mail store, Home Depot or Lowe’s and be able to print on textiles right then and there.

美国Mutoh公司的产品经理 Randy Anderson说,他希望在不远的未来,顾客可以在当地的家居用品店或者标识店铺里挑选物品,Home Depot(美国家居连锁店——家得宝)好Lowe’s(全球第四大广告代理机构——灵狮)都可以当场进行织物喷绘。

For the home design market, having the ability to match paint with cushion material, drapes and shower curtains is the next step. “Whether Home Depot does it or they subcontract someone to do it, I think it is coming,” he says.

对于家居设计这个市场而言,完全可以将喷绘应用到缓冲材料上,窗帘和淋浴帘也是一个可以考虑的领域。他说:“无论Home Depot是自己做还是外包给其他的公司,这是一个势不可当的趋势。”

Anderson doesn’t believe that textiles are just for large applications like wall coverings, flags and banners, but smaller applications as well. “That is our number one growth area right now,” he says. Fabric signs last just as long outdoors as vinyl and they are easier to handle and harder to damage. Once the ink is embedded in the fabric, it’s permanent.

Anderson不相信织物只用于大幅面工程,如壁画,旗帜和横幅等,小幅面应用依然可以。他说:“这是我们位列第一的增长点。”织物软标识在户外标识的使用上与亚克力是一样的,并且它还容易安装管理,不易损坏。一旦打印完成,效果即是永久性的。

Anderson also envisions a day when textile printers will include a heat press attachment so that shops can start a job and finish it on the same piece of machinery. Currently, print shops have to invest in expensive heat press equipment along with their wide-format direct to fabric printer. That’s why most sign shops that get into fabric printing start out with a smaller, cheaper machine, which can add new revenue streams without too much outlay on their part.

Anderson也希望有一天织物打印机上增加热压工艺,这样一来,打印和加工就可以在同一台设备上了。目前,打印服务供应商只能高价购买宽幅织物喷绘设备与热压工艺设备。这就是为什么大多数的标识公司在进入织物打印的领域时以便宜的小型设备开始,这样不仅可以增加额外收入还不需投入太多。