Duets by Gemini state-of-the-art Class 10,000 clean room is a climate-controlled facility with automation-controlled temperature and humidity to eliminate risk of dust, debris or other contaminants. Photo courtesy of Duets by Gemini.

Duets by Gemini公司的绝对无尘室是一个带有自动调节温度与湿度的恒温设备,它可以防止灰尘、碎屑以及其他污染物的进入。

As the laser engraving industry continues to grow and expand, companies are devising new products and substrates that can be decorated using lasers. Different types of acrylic are the biggest sellers when it comes to laser engraving, but wood, metal, rubber and even faux leather are growing in popularity.

随着激光切割行业继续发展和壮大,很多公司相继开发出适合激光加工的板材和产品。说到激光雕刻,多种多样的亚克力切割制品是最畅销的产品,但木材、金属、橡胶、甚至人造皮革也越来越常见。

Dave Johnson, director of operations at Johnson Plastics in Minneapolis, believes that at least three-quarters of the materials used in laser engraving are acrylics or modified acrylics. When plastics first came out for signs, the majority of them had a core called ABS, which melts under the heat of a laser.

Dave Johnson 是Johnson塑料制品有限公司的运营总监,他坚信,激光雕刻材料市场上,四分之三的材料是亚克力或者改进的亚克力制品。当塑料刚被运用到标识行业中时,它们都有一个核心材料简称ABS,所以它们才能在激光的高温下融化。

“Companies had to reformulate the sheet stock,” Johnson says. “What it is now is modified acrylic. For acrylic in its pure form, laser is the best. It doesn’t melt. It doesn’t warp. The edges aren’t sticky. The more acrylic in the base, the easier it is to engrave or cut out.” Duets by Gemini, in Cannon Falls, Minnesota, manufactures substrates that can be used in both laser and rotary engraving. Duets makes plastics with ABS for the rotary engraving market and acrylics for the laser market.

Johnson说:“材料供应商们不得不重新制造板材,这就形成了市场上改进的亚克力。纯粹的亚克力板材,激光雕刻是最合适的。它不会融化,不会弯曲变形,边缘也不会粘连在一起。板材中亚克力含量越多,激光雕刻或者切割就越方便。”位于美国中北部明尼苏达州的Duets公司生产的亚克力板材既可以激光切割又可以福伦雕刻。Duets公司的亚克力板材中添加了合成树脂ABS。

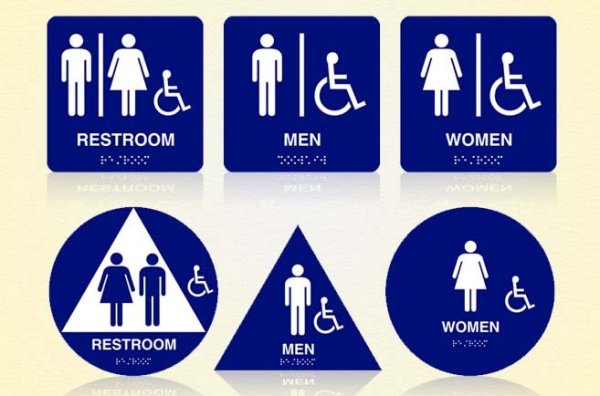

Sign shops can laser cut the figures that grace ADA-compliant signage. Photo courtesy of Johnson Plastic.2

标识公司可以按照设定的数据激光切割ADA兼容标识。

Gary Harder, director of Duets by Gemini, says that he still sees great demand for laser engraving in the sign industry but that awards, trophies and plaques are rising in popularity. Name badges are another great market to get into because many large corporations will go through tens of thousands of badges a year. “It is a great product for engraving plastic because the perceived value is high but the material cost is low,” Harder says.

Duets公司的主管 Gary Harder说,他在标识行业中看到了用于激光雕刻和切割的亚克力板材的巨大需求,而且,奖章、奖杯、奖品的制作中对亚克力的需求也持续扩大。胸牌(佩戴在胸前的名牌)是另一个可以进军的市场,因为很多大型的贸易公司每年在这方面都有高达几万美元的预算。Harder说:“胸牌是一个雕刻亚克力非常好的产品,它的产品感知价值很高,但是材料成本很低。”

ALTERNATIVES TO METAL

金属的替代物

“Many plastics manufacturers have come up with acrylic products that look like brushed aluminum or stainless steel and “those products go over very well. They are easy to engrave and look like metal and there isn’t an extra process of oxidizing,” Johnson says.

面对市场需求多样化的形式,很多亚克力材料制造商都想到让亚克力制品看起来像拉丝铝或者不锈钢。Johnson说:“这种亚克力的市场反响非常好。它们很容易雕刻而且具有金属的视觉效果,并且不需要额外的氧化处理。”

Customers who want to engrave on real aluminum or brass have to apply a real chemical to it afterward to get the letters blackened. “It is very easy for laser to cut it out instead of sheer cutting metal. The laser beam goes right through the plastic like butter and produces a very high-quality product,” Johnson says. ADA signage is one of the best segments of the signage industry to get into because most companies need almost an unlimited supply of ADA-compliant signs. More and more sign shops are using lasers to make these signs.

客户想在真正的铝或者其他金属材料上雕刻时必须在字母变黑后再促成化学反应。Johnson说:“激光切割雕刻亚克力比切割纯粹的金属材料要容易很多。激光光束穿透塑料就像切黄油面包一样容易,雕刻质量非常高。”在标识行业中必然要涉足的就是ADA标识,它的市场需求也是无止境的。越来越多的标识公司都在使用激光切割术加工制造这类标识。

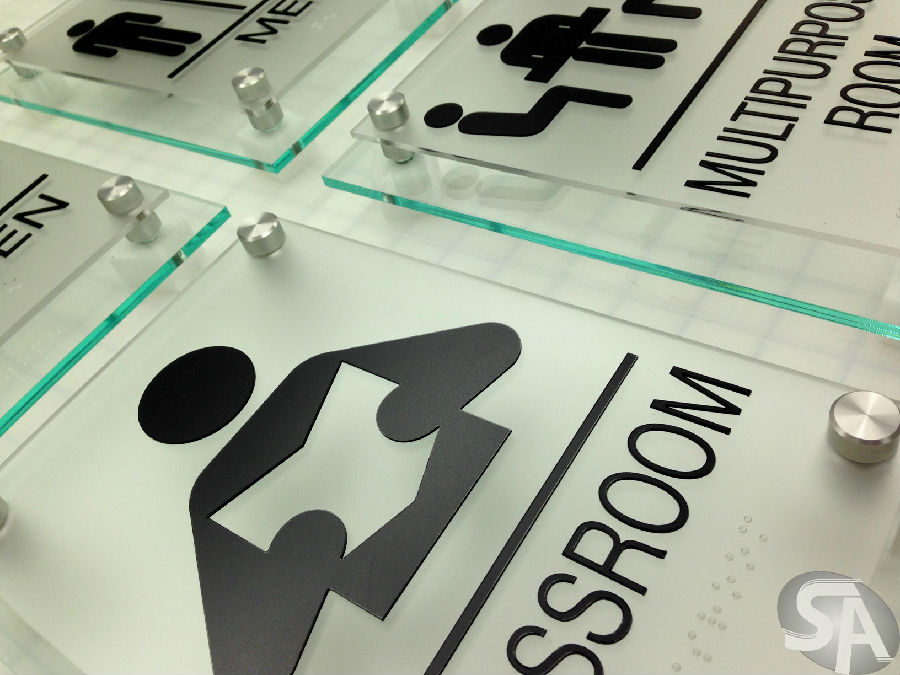

Duets by Gemini DuetsTactiles(TM) plastic sheet stock for ADA, appliqué and way finding applications is available in the industry’s most requested colors, patterns and finishes. Photo courtesy of Duets by Gemini.

Duets公司专为ADA标识生产的TM塑料薄片,在导视系统中常见的颜色、模式和装饰方式,它都能适应。

“In the past it was always done by a rotary engraving machine but shops are finding that the laser can cut them out quicker. The only thing it can’t do is drilling holes into the substrate and inserting the beads of acrylic in there, the braille part,” Johnson says. ADA signs are the most profitable signs to make, he adds. There is a bit more labor involved but what would have been a small $15 sign becomes a $45 one when the braille beads are added.

在过去,ADA标识都是用扶轮雕刻机制作的,后来标识公司发现,激光切割机处理这类工作更快、质量更高。激光切割机唯一做不到的工作就是在板材上转孔、插入亚克力粉,形成盲文印。他补充道,ADA标识是最有利可图的一类标识。虽然,它需要的劳动力相对多一些,但是,一个价值15美元的标识加入盲文印后就可以卖45美元了。

Many companies are experimenting with laser cutting rubber to make stamps, while others search for personal items, such as mugs, that cost very little to make but are easily engraved. Even though plastics that look like metals are popular, industrial customers are still interested in metals, like stainless steel, brass and aluminum.

很多公司也在尝试用激光切割机切割橡胶用于制作图章,还有一些其他的私人用途,如马克杯,它们制作成本少又容易雕刻。即使有些亚克力具有金属的外观,受人欢迎,但是工业用户还是对金属情有独钟,如不锈钢、铜、铝等。

A new product called CerMark, invented by Ferro, comes in liquid, spray or paste. Engravers apply a dab of it on stainless steel or other raw unfinished non-coated metals. When the laser hits it, it puts a permanent black mark on the metal. This is an easier process than traditional rotary engraving, he says. It also looks nicer and allows a customer to include more detail. It is very popular for sign applications and for labeling equipment.

一个叫CerMark的新产品,是一个叫Ferro的人开发的,可以以流体、喷雾、糊状存在。雕刻师用药棉蘸着涂在不锈钢或者未加工的生金属表面。当激光照射时,它就会形成一个永久的黑色印记。这种方法比传统的扶轮雕刻简单很多。它不仅更美观、还包含很多其他的细节加工。是非常实用和受欢迎的标识加工设备。

JDS Industries offers a variety of engravable gift items, such as Wine Boxes, BBQ Sets and Flask Sets.

JDS行业工具包装盒需要一系列的雕刻工艺,例如红酒包装盒、烧烤工具盒等。

Harder says that he has seen a huge leap in demand for laser engraved stainless steel mugs. The laser engraver sprays CerMark on it, hits it with a laser and then washes off the black, leaving crisp engraved lettering. “These are very popular, especially with the holidays coming up,” he says. Many companies are trying to get into this market because the mugs are fairly inexpensive to make but with laser engraving on them can be sold for $30 to $40 a mug.

Harder表示,他看到了市场对激光雕刻不锈钢需求的巨大增长,激光雕刻师在不锈钢上撒上CerMark这种材料,用激光照射,然后洗掉黑色,留下漂亮的雕刻字体。他说:“他们非常受欢迎,尤其是假期来临的时候。”很多企业在这个时候都想进入这个市场,因为这种杯子制作起来非常便宜,但是杯上增加激光雕刻之后,售价就在30到40美元之间了。

“Ultimately sign shops want to listen to their customers. They are the ones driving the needs. If they want plastic over metal, those options are available. If they want metal, that is available. Using a laser on both is just as easy,” Johnson says. There isn’t a ton of innovation as far as substrate materials go, but manufacturers have made their mark by adding new color schemes and adding textured finishes on the material as opposed to just a matte or glossy finish. “That’s where we see the innovation. I’m not sure that’s innovation. Just more options,” he says.

Johnson说:“最终,标识公司都听从他们客户的指引,他们引导着市场需求。无论他们想要塑料还是金属制品,激光雕刻都可以胜任。即使是金属雕刻也同样简单。”标识基板不需要太多的创新,但是,制造商们都通过增加板材的颜色配置和纹理表现而不是一般的哑光板,来区别于市场上的其他同类产品。他说:“这就是我们看到的创新。或许这不属于创新,只是为我们提供了更多的选择。”

Earl's: Laser-engraved signs made from textured plastic that is durable for exterior uses. Photo courtesy of Johnson Plastic.

Earl's:用带有纹理的亚克力加工的激光切割标识在户外标识中很普遍。

Mike May, COO of JDS Industries in Sioux Falls, S.D., says that plastics are definitely the most popular substrates for laser engraving but since the Great Recession began in 2008, he is seeing more sign shops branch out and use their laser engravers to personalize promotional products, incentives and customer and employee gifts. Everyone is looking for additional sources of revenue with their existing equipment.

Mike May,JDS产业在苏福尔斯的首席运营官,他说,亚克力板材是激光雕刻中最常见的板材,但是从2008年爆发的经济危机引起的大萧条开始,他发现很多标识店铺将激光雕刻应用于其他方面以拓展业务。每个人都希望能在原有的设备上赚取额外的收入。

Plastic isn’t used as much in the gifts and incentives market. It is used more for interior signage. Promotional items are made from all kinds of materials, including stainless steel, solid woods, bamboo, aluminum and anything else that lasers well, he says. JDS Industries is the largest supplier in the world for component parts for anything personalized. It sells awards, trophies, badges, signage, personalized gifts and photo gifts to various retail stores. It has 14 warehouses nationwide with nearly one million square feet of distribution space and more than 13,000 products.

他说,塑料很少作为礼物或者奖品,它大多应用于室内标识领域。赠品所用的材料很多,包括不锈钢、实木、竹子以及其他可以激光雕刻的材料。JDS Industries是世界上最大的个性化产品零部件的供应商。他们出售奖品、奖杯、徽章、标识、个性化赠品以及各种零售商店的照片。它在全美国范围内有14间仓库(大约占地一百万平方英尺),其中包含13000件产品。

Into Leather

皮革材料

JDS Industries features Laserable Leatherette in Black that lasers to an elegant gold finish, and Light Brown and Dark Brown that laser to black for a great contrast.

JDS Industries生产的用于激光雕刻的黑色的人造皮革可用激光雕刻出很多高雅的金黄色标识,上述展示了浅棕色、深褐色以及黑色人造革的鲜明对比图。

One of JDS Industries’ most popular lines is laserable leatherette. It is available in dozens of different products, including picture frames, plaques, portfolios, coasters, business card holders and drink holders, such as latte sleeves. “It is synthetic leather but it looks and feels like leather. The advantage is it is very consistent compared to leather,” May says. “Consistency is important. The whole point of lasering is to focus light to burn material so the surface has to be consistent. The leatherette is affordable; it has a high perceived value, looks great and lasers great. It gives retailers a great opportunity to make a good profit margin.”

JDS Industries公司最常用的材料是可以雕刻的人造皮革。它广泛地应用于相框、奖杯、宣传册、垫子、名片夹等产品中。May说:“它虽然是合成革,但是视觉和触觉上都很像皮革,这是它最大的优点。可溶性是前提,激光雕刻主要是通过光束聚焦到材料的表面,高温使材料融化。人造革很便宜,而且外观漂亮,适合激光切割。为零售商们提供了一个高利润业务的机会。”

Good Old Wood

经久耐用的老木材

Wood is also popular because it is easy to engrave. “Anything out of wood you can personalize is popular. Wood also has the benefit, like acrylic, of low material costs and high perceived value,” Harder says.

木材很受欢迎是因为它容易雕刻。Harder说:“在个性化雕刻方面,木材最受欢迎。木材的利润和亚克力相似,材料成本低而利润率高。”

Options Are Limitless

多样的选择

Gravotech, Inc. manufactures different substrates that are perfect for laser engraving. Its Gravoply Ultra is “great for indoor, outdoor, rotary, laser (cutting and engraving) and UV printing,” says Terri Bristow, marketing specialist with the Duluth, Ga.-based company. “This material helps increase profits by allowing you to stock only one material type for multiple applications. Since you can create your own custom color combinations, the options are limitless.”

Gravotech有限公司生产了大量的基板都是非常适合激光切割的。他们的Ultra系列产品非常适合室内外标识、扶轮雕刻、激光雕刻和切割以及UV打印,Ga.-based公司的市场专家如是评论:“有了这种材料,你就可以将它应用于多种领域,利润空间将会更大。既然可以让顾客自定义颜色组合,那就有无数个选择方案了。”

Gravotech also makes a product called Rubbalase, which is perfect for making stamps. “Not many engraving shops manufacture stamps, which is why it can be an additional revenue stream for some. This material can only be engraved by laser and comes in an odorless option for those that do not like the smell of burning rubber,” Bristow says.

Gravotech公司也生产了一款产品并命名为Rubbalase,它非常适合制作图章。Bristow说:“很少有激光切割服务供应商会生产图章,这就是为什么激光切割服务商会有一笔可观的额外收入。这种材料只能用激光切割才不会产生橡胶燃烧的气味。”

Exterior wayfinding signs are a key component to any business’ success. This directory was created using Durablack, a CO2 laser engravable aluminum designed to excel in harsh environments. Photo courtesy of Gravograph.

Exterior wayfinding signs are a key component to any business’ success. This directory was created using Durablack, a CO2 laser engravable aluminum designed to excel in harsh environments. Photo courtesy of Gravograph.

在标识行业中,户外导视系统占据着重要部分。这种标识是用Durablack的二氧化碳激光雕刻机在铝合金上精加工而成,具有很强的耐候性。

Findlay, Ohio-based Rowmark also manufactures laserable substrates. Its best-selling product is called LaserMax, which is a UV stable micro-surfaced, impact modified acrylic sheet that “engraves beautifully in a single pass,” says Bobbi Payne, customer and technical support specialist at Rowmark. The material is available in numerous colors and also features unique patterns like metallic, woodgrain and marble.

最后,俄亥俄州的Rowmark也生产了一系列的可激光切割的板材,其中最畅销的是一款叫做LaserMax的产品,这是一款抗紫外线的多层材料,是改良版的亚克力板。Rowmark 的技术顾问Bobbi Payne说:“LaserMax亚克力板单条刀轨激光切割的也很完美。”这种材料不仅颜色众多而且可以在外观上模仿金属、木材和大理石。

The company’s Metalgraph Plus material is one of Payne’s personal favorites. It is available in four unique metallic finishes and also lasers in a single pass. “This stunning product line looks like real metal yet it has all the product features and ease of use of plastic,” Payne says.

该公司的Metalgraph Plus系列材料是Payne个人最喜欢的材料之一。它也可以模仿四个独特的金属表面,也可以单条刀轨激光切割。Payne说:“这款产品看起来像金属,而且具有金属的特性,大大解放了塑料的用途。”

“Profitability for the laser engraver is contingent on a number of things. Obviously material costs, but fabrications also need to consider design, project layout time, machine time, assembly and clean up. Also contingent in the engraver’s profitability will be their market focus and the margins their market will support,” she adds.

她说:“激光切割的利润取决于很多因素。首先是材料成本,然后加工过程还包括设计、项目布局、设备运行成本、装配以及清理等。当然,最重要的市场需求,售价和销售量等因素。”