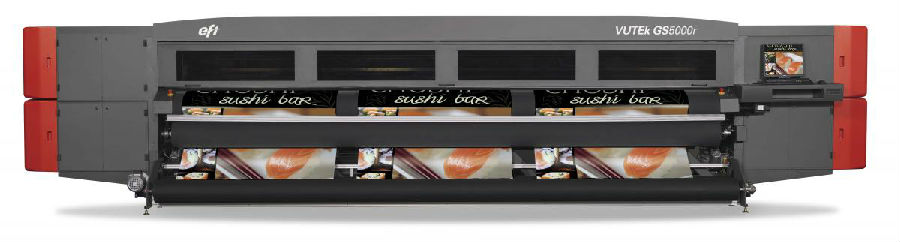

Large-format inkjet printers are computer controlled printing devices that support wide substrate rolls, sometimes more than 100" wide. Printers with capacities over 100" wide are considered to be super-wide or grand format (see Figure 1). The price range of these devices is as wide as the surfaces they print on—from as little as about $20,000 to well over a half million or more.

宽幅喷墨印刷机是由计算机控制的印刷设备,它支持宽幅面的材料印刷,其印刷的材料宽度有时会超过100英寸。通常,可以印刷宽度超过100英寸的印刷机都可以被称为宽幅喷墨印刷机(见图1)。这些设备的价格视它们可以印刷的幅面而定,从两万美元到高于五十万美元不等,甚至更多。

Large-format printing has grown in popularity over the past 25 years and is now a common technology used in many sign and commercial graphics shops. Creating oversized prints of high-quality digital images on a large variety of surfaces is central to signage and commercial graphics. I thought this would be a good time to take stock of the printing equipment and technologies in use today.

宽幅印刷技术在过去25年中日益普及,现在已经成为许多标识制作和商业图形商店中常用的技术。在各种材料表面上印刷高质量的宽幅数字图像是标识制作和商业图形的核心技术。我认为现在就是评估如今使用的印刷设备和技术的一个好时机。

Applications

宽幅喷墨印刷的应用

Large-format printers are used to print signage, banners, posters, trade show graphics, wallpaper, murals, flags and textiles, fine art, billboards, backlits and vehicle wraps—not to mention electronic circuit schematics, architectural drawings, construction plans, theater backdrops and media sets . Large-format prints are extensively used as high-impact advertising media. Let's look at some of the technologies being applied.

宽幅印刷机常用于印刷标牌、横幅、海报、展览展示图形、壁纸、壁画、旗帜、纺织品、精细工艺图形、广告牌、背光板、车辆包装图形、电子电路原理图、建筑图纸、施工计划和剧院背景图形等。目前,宽幅印刷技术正广泛应用于高影响力的广告媒体。现在让我们来看一下那些正在被应用的宽幅图形印刷技术。

RGB Printers

RGB印刷机

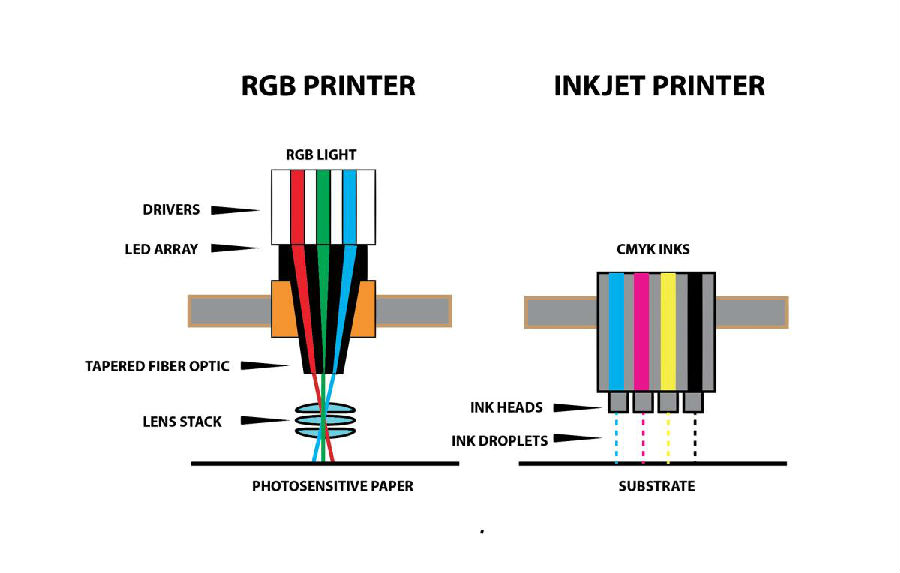

I’ll start with the least common type of printer—the RGB printer. RGB printers don’t use ink. They are photographic printers that transfer colored light onto photosensitive paper, (see Figure 2). An RGB printer known as LightJet was originally developed by Cymbolic Sciences in the early 1990s to write to 8"×10" photographic film. These "digital originals" were indistinguishable from scanned slides and negatives, and prints had the look and feel of a traditional photograph, and offered resolutions of about 4,000 dpi.

我将从最少见的印刷机——RGB印刷机开始说起。RGB印刷机在工作时一般不使用墨水,它是将彩色光线转印到感光纸上的照相印刷机(见图2)。被称为LightJet的RGB打印机最初由美国Cymbolic科学公司于20世纪90年代初开发,可以打印8英寸×10英寸大小的摄影胶片。 这种“数字原件”与扫描的幻灯片和摄影底片几乎没有区别,并且印刷出来的照片具有传统照片的外观和质感,还可以提供约4,000 dpi的分辨率。

Later Oce acquired Cymbolic Sciences and a large-format version of the LighJet was developed—along with competing brands such as the Durst Lambda. These units had the capability of writing much larger digital images directly onto photographic paper and backlit duratrans film using colored lasers. Though fairly popular among commercial graphics shops some years ago, their expense and limited substrate options have made them less popular, especially as the quality and speed of highly versatile, less expensive inkjet systems emerged.

后来,在Oce公司收购了美国Cymbolic科学公司之后,宽幅印刷版本的LighJet机型就和Durst Lambda等竞争品牌一起得到了发展。这些设备可以使用彩色激光技术将大量的数字图像直接印刷到照相纸或背光透明塑料膜上。早年这种技术在商业图形商店里运用得十分广泛,但是由于成本和耗材选择的限制,尤其是高品质、高速度和低成本的喷墨系统的出现,就使得这种技术慢慢的不受欢迎了。

Piezo & Thermal Inkjet Technology

压电和热喷墨技术

The two most common printhead systems in today's inkjet printers employ either thermal technology or piezoelectric technology.

如今喷墨印刷机中最常见的两种喷墨头系统采用的是热喷墨技术和压电式喷墨技术。

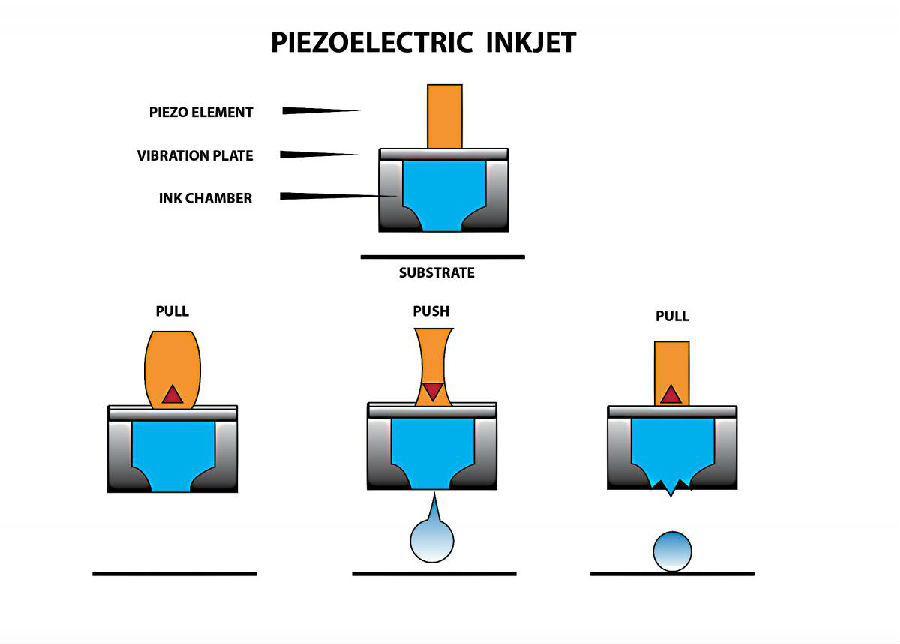

Piezoelectric printhead technology, which was first introduced by Epson in 1964, employs piezo-ceramic crystals at the rear of each printhead ink reservoir. When an image file is RIPed and electronic data is sent to the printheads, an electric charge excites the piezo crystals causing them to expand and contract at very specific frequencies. The pulsing of the crystals drives ink in the printhead reservoir so that a tiny droplet of ink fires out of the nozzle and onto the substrate, (see Figure3Piezoelectric printheads are quite durable, are used in a wide variety of inkjet printers, and can accept a wide variety of ink types.

爱普生在1964年首次提出压电式喷墨头技术,在每个喷墨头墨水盒的后方使用压电陶瓷晶体。当图像文件经过RIP处理之后,其电子数据就会被发送到喷墨头,此时电荷就会刺激压电晶体,让它们在一个特定的频率里膨胀或收缩。晶体在经过膨胀或收缩后所产生的脉冲可以驱动喷墨头储存器中的墨水,使得一小滴油墨从喷嘴中喷到材料表面(见图3)。压电式喷墨头非常耐用,既适用于各种喷墨打印机,也可以接受各种类型的墨水。

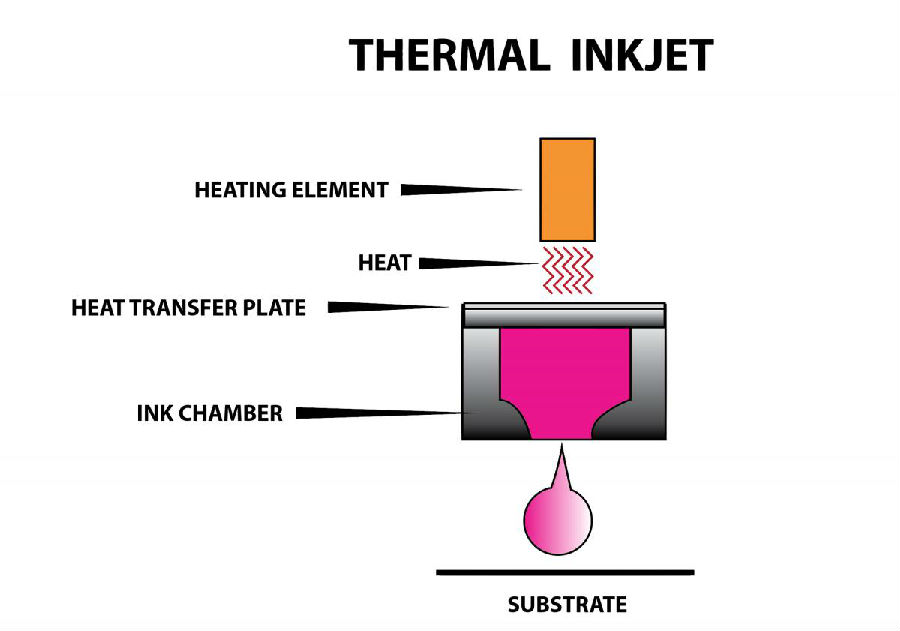

Thermal inkjet technology—used only with aqueous-based ink systems—employs heat behind the ink reservoir in the printhead. A RIPed file sends the data to the printheads causing a pulse of heat that in turn forms a tiny bubble in the ink chamber. The bubble fires an ink droplet out of the nozzle and onto the substrate (see Figure 4).

热喷墨技术(仅用于水性油墨系统)。这种技术是在喷墨头油墨盒的后方使用热量作为压力。当图像文件经过RIP处理之后,其电子数据被发送到喷墨头就会产生一股热脉冲,从而在墨水盒中形成微小的气泡,这个气泡就会帮助墨滴从喷嘴中喷到材料表面(见图4)。

Both thermal- and piezo-based inkjet printers can generate professional-quality, high-resolution large-format images. Some photo print shops use archival aqueous inks that have proven to be better than the standard ink for long-term durability. Archival inks are humidity and light resistant and claim to last for as much as a century rather than fading over time. They have a protective resin coating that increases durability and an impressive color gamut keeps photos true to the original image.

热喷墨印刷机和压电式喷墨印刷机都可以印刷专业品质的高分辨率宽幅图像。一些照片印刷商店使用的档案专用水性油墨已经被证明比标准油墨更加的持久耐用。档案专用水性油墨具有保湿和耐光性的特点,并且不容易因为时间的流逝而褪色。它们具有提高耐用性的保护性树脂涂层,颜色丰富的色域也会使照片保持原始图像的颜色。

Aqueous Ink: Dye vs. Pigment

水性油墨:染料VS颜料

Both thermal and piezo inkjet printheads can deposit aqueous (water-based) inks. The term "water-based" is an industry-accepted misnomer. The colorant is actually suspended in a neutral carrier solution that may be water or a soy-based liquid. Generally aqueous prints are used for interior applications, but with lamination can also be used outdoors.

热喷墨和压电式喷墨头都可以储存水性(aqueous)油墨(术语“water-based”是业界公认的一个误称)。实际上,着色剂可以悬浮在比如水或是大豆基液体的中性溶液中。通常水性油墨印刷产品多应用于室内,但是在经过层压处理之后也同样可以应用于室外。

Various substrates are available for aqueous printing, including many types of matte, semi-gloss and glossy papers, canvases, vinyl, and cloth. Aqueous technology requires that these materials be coated to accept and hold the ink, and to control dot gain.

很多材料都可以使用水性油墨印刷,比如磨砂纸、半光泽纸和光泽纸、帆布、乙烯基材料和布料。水性油墨技术要求这些材料在得到印刷后可以充分吸收和保持墨水,并且尽量减少油墨晕染问题的出现。

Colorants in aqueous inks come in two varieties: dyes and pigments. Dyes rely on dispersed organic (plant-based) materials for their color while pigments use finely ground inorganic materials.

应用于水性油墨的着色剂有两种:染料和颜料。染料多使用分散的有机(植物)材料着色,而颜料则使用精细的无机材料着色。

Dye-based inks offer the widest color gamut and produces intense colors, but prints can fade in time when exposed to ambient UV light. For this reason dye-based inks are primarily used for indoor printing. Pigment-based inks are less vivid, but offer much better resistance to fading due to UV rays. Finished aqueous prints should be laminated and encapsulated if they are to be displayed outdoors.

使用染料的水性油墨在提供较为广泛的色域的同时,还可以提供颜色鲜艳的视觉效果,但是当其印刷产品暴露于紫外线下时,就会很容易发生褪色现象,因此,使用染料作为着色剂的水性油墨主要用于室内印刷。使用颜料作为着色剂的水性油墨虽然不是特别鲜艳,但是它拥有非常好的防紫外线特性,不容易褪色,如果要在室外使用水性油墨,那么就应该在最后完成时对印刷好的材料进行层压和封装处理。

Solvent and Eco-Solvent Inks

溶剂和生态溶剂油墨

Traditional true solvent inks consist of color pigments suspended in petroleum or a petroleum by-product such as acetone or ketone as a carrier. Due to the presence of hazardous VOCs (volatile organic compounds) emitted by true solvent inks, they are not used in the U.S. as widely as they once were.

传统的溶剂型油墨由漂浮在石油表面的彩色颜料,或由丙酮或酮等石油副产品作为原料制作而成。由于传统的溶剂型油墨会散发危险的挥发性有机化合物(VOCs),所以它们现在并不像以前一样广泛地在美国使用。

More ecologically friendly eco-solvent and light-solvent inks are widely used today. They employ less toxic glycol esters as the carrier, and are an effective waterproof outdoor printing solution, but they produce slower drying prints. Most eco-solvent printers can be used in an office environment with minimal or tolerable odor levels, and very low VOC levels.

更环保的生态溶剂和轻溶剂油墨在今天得到了广泛的使用。它们的制作材料很少使用具有毒性的乙二醇,并且这种溶剂在户外使用时能够有效地防水。但是经由它们印刷的产品干燥速度较慢。大部分生态溶剂印刷产品都可以在办公环境中使用,其散发的气味几乎不可察觉,VOC含量非常低。

Latex Inks

乳胶油墨

Another type of water-based ink used in wide-format print production is called Latex inks. HP developed the technology as an outdoor printing alternative to light- and eco-solvent technology, and introduced it to the market in 2008. Latex inks are pigmented, water-based inks employing an aqueous-dispersed polymer (“Latex”) technology that gives these aqueous inks outdoor durability with very few environmental concerns.

另一种用于宽幅印刷生产的水性油墨被称为乳胶油墨。惠普公司就在发展这种技术,他们将乳胶油墨作为户外印刷的主要油墨来代替轻溶剂油墨和生态溶剂油墨,并于2008年向市场进行推广。乳胶油墨可以直接进行着色,其水性油墨采用水性分散聚合物(“Latex”)技术,这种技术增加了水性油墨的户外持久性并且非常环保。

HP Latex printers—Designjet series and HP Scitex printers—use internal radiant heaters and forced airflow to drive off water and cure the inks, producing dry, ready-to-use prints.Prints can be laminated immediately using cold, hot, or liquid processes. The company claims un-laminated durability of three years for outdoor applications, and up to five years for indoor displays.Printers to produce vivid, durable prints on a wide variety of coated and uncoated materials including most low-cost, eco-solvent/low-solvent compatible media.

惠普Latex印刷机(Designjet系列和HP Scitex印刷机)使用内部辐射加热器和强制气流来干燥水分并固化油墨,可以生成干燥的即用型印刷材料。其材料可以使用冷、热或液体方式进行层压处理。并且公司声称即使是没有经过层压处理的材料,也可以在室外使用三年,室内使用则长达五年。印刷机可在各种涂层和无涂层的材料上印刷出颜色鲜艳并且耐用的成品,这些材料包括大多数低成本、生态溶剂或者轻溶剂兼容介质。

In recent years Mimaki and Ricoh have developed similar Latex printing systems.

近年来,Mimaki和理光都开发过类似的胶乳油墨印刷系统。

UV-Curable Inks

紫外线(UV)固化油墨

UV-curable inks work in an entirely different way than aqueous or solvent inks. In addition to the pigment colors, they are a chemical soup consisting mainly of monomers and oligomers and a photoinitiator catalyst that, when exposed to a strong source of UV irradiation (an arc lamp or LED-based cure lamp) become a solid. The monomers and oligomers chemically change into a solid polymer. Most wide-format UV-cure printers used in the sign industry have cure lamps mounted on the printhead and cure the deposited inks with every pass of the printhead.

UV固化油墨与水性或溶剂型油墨的工作方式完全不同。除了颜料颜色之外,它们的化学组成成分主要是由单体和低聚物组成的,当暴露于强烈的紫外线光照(弧光灯或LED固化灯)下时,光引发剂就会发生固化反应,单体和低聚物发生化学反应转变成固体聚合物。应用于标识行业的大多数宽幅紫外线(UV)固化印刷机具有安装在喷墨头上的固化光照灯,每当喷墨头喷出油墨时固化灯就会对油墨进行光照固化作用。

UV-cure printing is viable on a huge range of substrates, and is especially useful for outdoor applications printed directly onto rigid substrates using a flatbed printer. Fully cured UV inks can be extremely durable and hard or remain quite flexible, depending on the formula used.

UV固化印刷适用于大部分基材,并且对于需要使用平板印刷机印刷的户外应用的刚性基材尤其有用。完全固化的UV油墨非常牢固耐用,并且在应用方面也十分灵活。

Dye Sublimation

染料升华

“Dye Sub” as it is called in the vernacular, is a method for digitally printing onto textiles. In this process, special sublimation inks—under heat and pressure—sublimate and diffuse into polyester-based media and fabrics, forming a permanent bond. There are two techniques used with dye sub: direct-printing to textiles and transfer printing.

“染料升华”简单来说就是将数字印刷应用到纺织品上的一种方式。在这个过程中,专用的油墨通过热量和压力进行升华,并被吸收到聚酯基介质和纺织品中,形成永久的粘合。染料升华有两种技术:纺织品直接印刷或转印。

For transfer printing, a reverse image is printed onto a special transfer paper which is then placed with the intended substrate in a heat press where the inks can then be sublimated to the fabric. These printers produce very durable photo-quality continuous-tone images. Dye-sublimation printing uses polyester and polymer-coated substrates and is used to print onto apparel, and poly-coated items such as cell phone covers, plaques, ceramic containers, etc.

说到转印,就是将一个倒转的图像印刷到特制的转印纸上,然后将其与预先准备好的基材一起放置在热压机中,再将油墨印刷到纺织物上。这些印刷机可以印刷非常耐用的接近照片图质的连续色调图像。染料升华印刷使用聚酯和聚合物包膜的基材,它多用于服装印刷,以及多涂层物品,如手机盖、瓷片、陶瓷容器等。

The heat press (clamshell/drum press), or calender unit uses a combination of time, temperature (380°-420°F.) and pressure, which vary depending on the substrate, to transfer the sublimation dyes at the molecular level onto the surface.

根据基材的不同,热压机(蛤壳式/鼓式压力机)或压光机的使用时间、温度(380°-420°F)和压力的大小也不尽相同,但最终目的还是要将图像以分子的形式转印到纺织品表面。

With direct printing, the printer deposits the dye sub inks directly onto the fabric which can then be run through a heat press—eliminating the need for a transfer process. Some direct-printing printers include a set of heated rollers (calender) that perform on-board sublimation.

再说直接印刷,印刷机将染料直接印刷在纺织品上,然后通过热压机运行的操作,无需转印过程,就可以将图形印刷在纺织品上。直接印刷的印刷机包括加热辊(压光机)系列,这一系列就可以在基材上进行染料升华操作。

Dye sublimation produces an extremely permanent, high resolution, full color print. The prints will not crack, fade or peel under normal conditions.

染料升华印刷出来的图像效果持久、分辨率高,并且是全彩色印刷。正常条件下,印花不会破裂,褪色或剥落。

Plotters

绘图仪

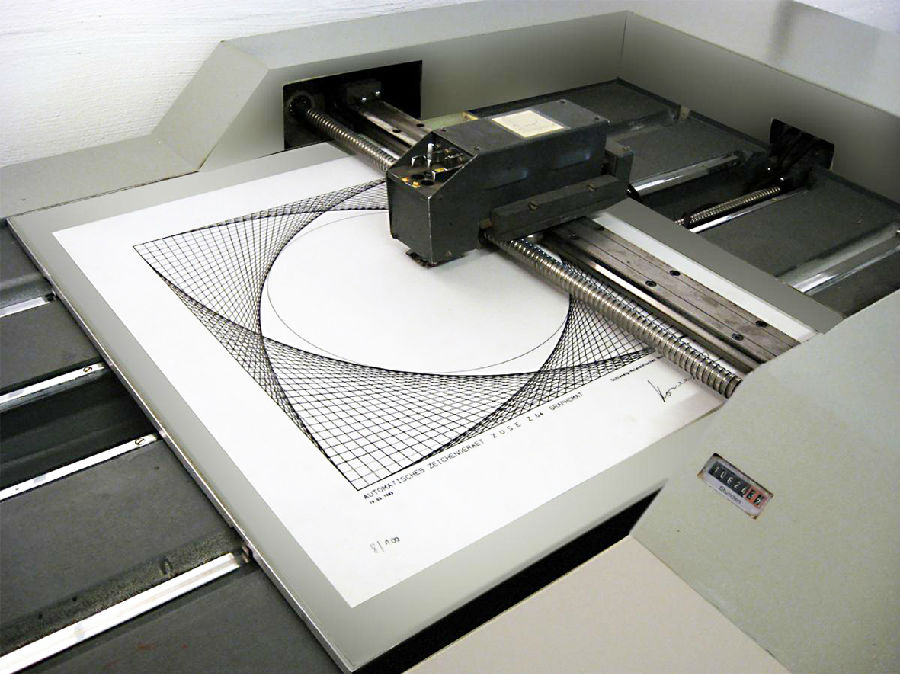

Plotters were the first type of printer that could print with color and render graphics and full-size engineering drawings. This technology is primarily used for producing CAD (computer aided design) and CAM (computer aided manufacturing) drawings. A plotter interprets data from a computer into line drawings on paper with one or more automated pens, (see Figure 7). The plotter can draw continuous point-to-point lines directly from a vector file. There are a number of different types of plotters the most common being:

绘图仪是第一个可以印刷颜色、进行图形着色和进行全尺寸工程绘图的印刷机。该技术主要用于生产CAD(计算机辅助设计)和CAM(计算机辅助制造)图纸。绘图仪可以直接将电脑上的矢量文件转换成连续的点对点线条,用一支或多支电子笔自动绘制在印刷材料上(见图7)。市面上有很多不同类型的绘图仪,以下我将列举几个比较常见的类型:

Drum Plotters—draw on paper wrapped around a revolving drum to create the vertical coordinates of the drawing. The pens move in a horizontal direction and draw on substrate.

滚筒绘图仪——对包裹在旋转滚筒上的纸张进行绘制,创建绘图的垂直坐标。笔在水平方向上移动并在基底上进行绘制操作。

Flatbed Plotters—draw on paper placed on a flat surface with pens that move both horizontally and vertically.

平面绘图仪——使用电子笔在平面纸张上进行水平或垂直绘制操作。

Electrostatic Plotters—draw on negatively charged paper with positively charged toner.

静电绘图仪——使用带正电的调色剂在带负电的纸张上进行绘制操作。

Vinyl Cutters—though not actually a printer, a vinyl cutter uses plotter technology to accurately cut shapes from vinyl sheets.

乙烯切割机——虽然这个机器实际上并不是印刷机,但是乙烯切割机可以使用绘图仪技术在乙烯基板上精确地切割出形状。

Printing

印刷

There are many variables that need to be considered before you push the print button.

在按下印刷按钮之前,需要考虑许多变量。

Considering the amount of material that is consumed by large-format printing and the length of time it takes to print a large-format document, it is essential to get the print right the first time, otherwise a lot of time and money can be wasted.

考虑到宽幅印刷的耗材以及印刷宽幅图形文件所需要的时间长短,首先对印刷的相关事宜进行预先的检查是至关重要的,否则就会导致大量时间和金钱的浪费。

That about covers the types of large format printers and their characteristics and capabilities. There are many brands and sizes on the market and you should consider what system is best for your particular needs.

其次需要考虑的就是宽幅印刷机的类型、特点及其功能。市场上有许多关于宽幅印刷机的品牌和尺寸,你应该考虑清楚你最需要的是哪一种印刷机的系统。